Ultrasonic knife bar assembly, ultrasonic knife thereof and ultrasonic knife control system

A technology of ultrasonic knife and components, which is applied in the field of medical equipment, can solve the problems of knife head wear, long-term no-load, high labor intensity, etc., and achieve the effects of accurate energy output, prolonging service life, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

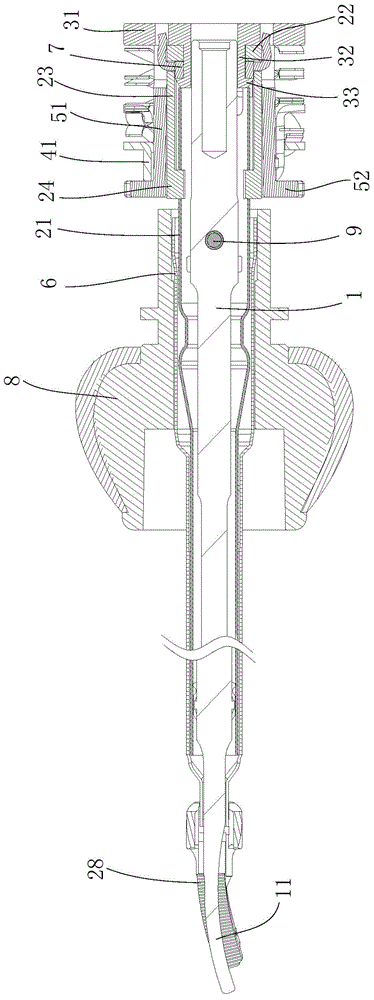

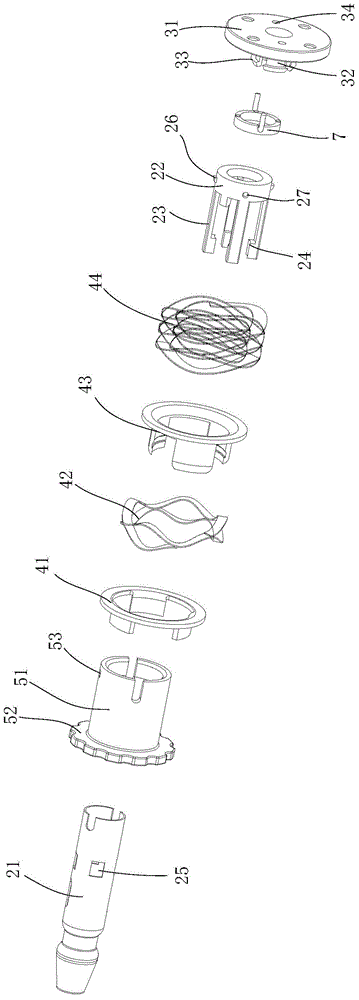

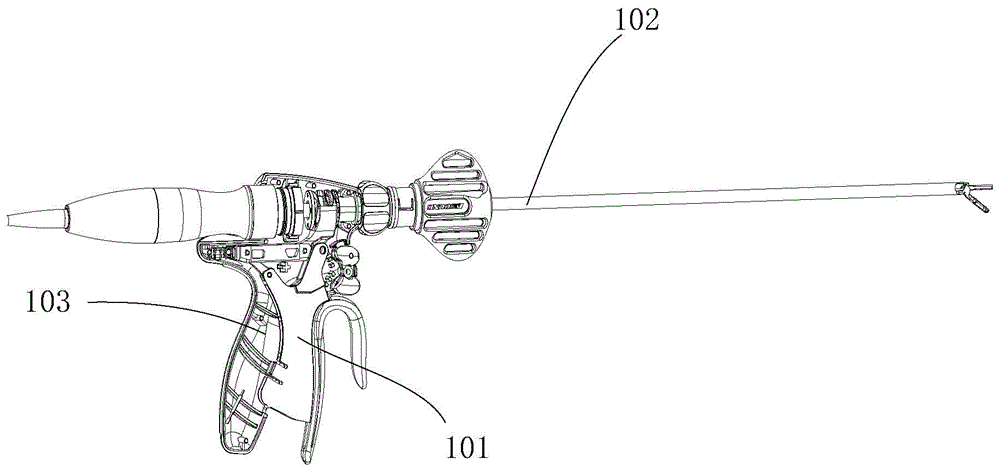

[0055] like figure 1 and figure 2 As shown, the present invention provides a kind of ultrasonic knife bar assembly, comprises the force transmission mechanism that is connected with the first half shear head 28 and is provided with the ultrasonic action rod 1 of the second half shear head 11, the first half shear head 28 and the second half shear head 28 The two halves of the cutting head 11 cooperate to form the jaw of the cutter head, and also include a pressure transmission component for receiving external toggle pressure and applying it to the force transmission mechanism, and a pressure detection element 7 is arranged between the pressure transmission component and the force transmission mechanism .

[0056]In this example, the force transmission mechanism includes an inner sleeve 21 and a connector connected to the rear of the inner sleeve 21. The inner sleeve 21 is set outside the ultrasonic action rod 1. The inner sleeve 21 is covered with an outer sleeve 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com