Coating composition for the prevention and/or removal of limescale and/or soap scum

A composition and coating technology, applied in the purpose of preventing and/or removing scale and/or soap residue on a substrate surface, in the field of preventing and/or removing scale and/or soap residue on a substrate surface, capable of solving complex application processes, troubles, Insufficient storage period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

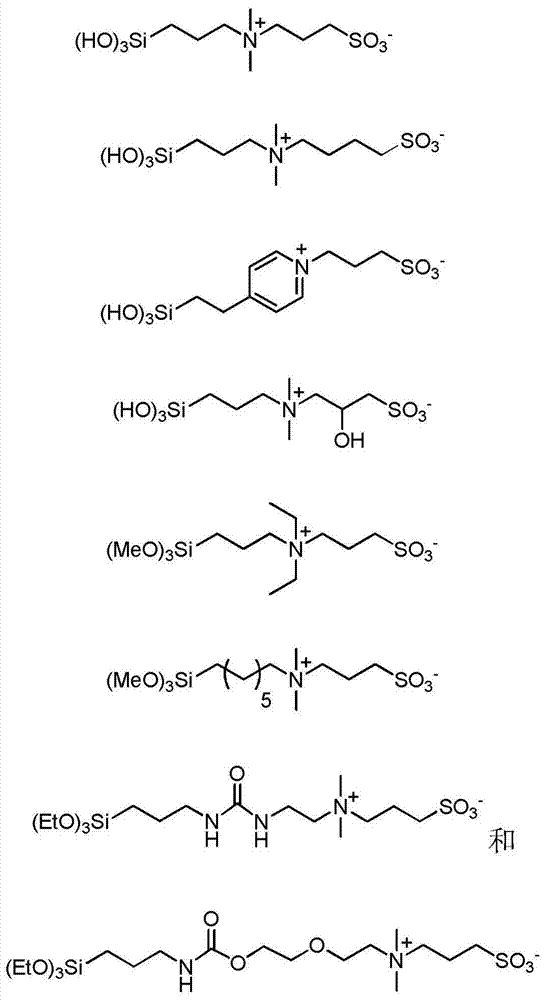

Method used

Image

Examples

example

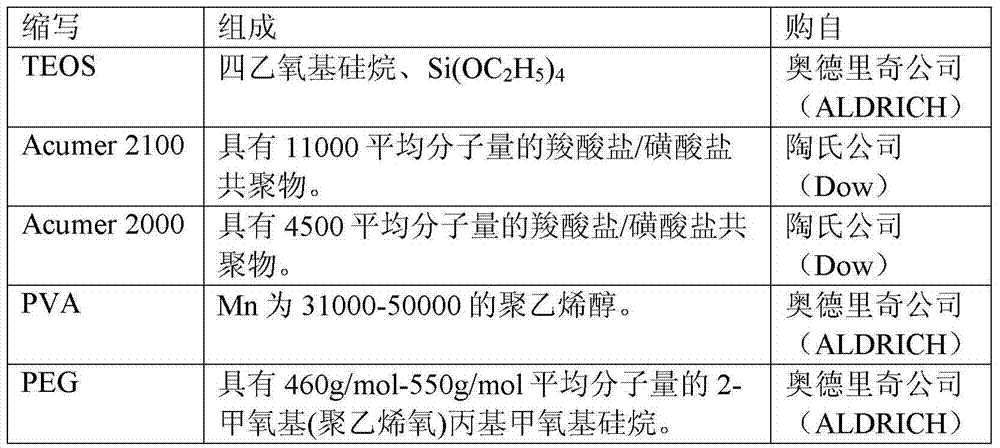

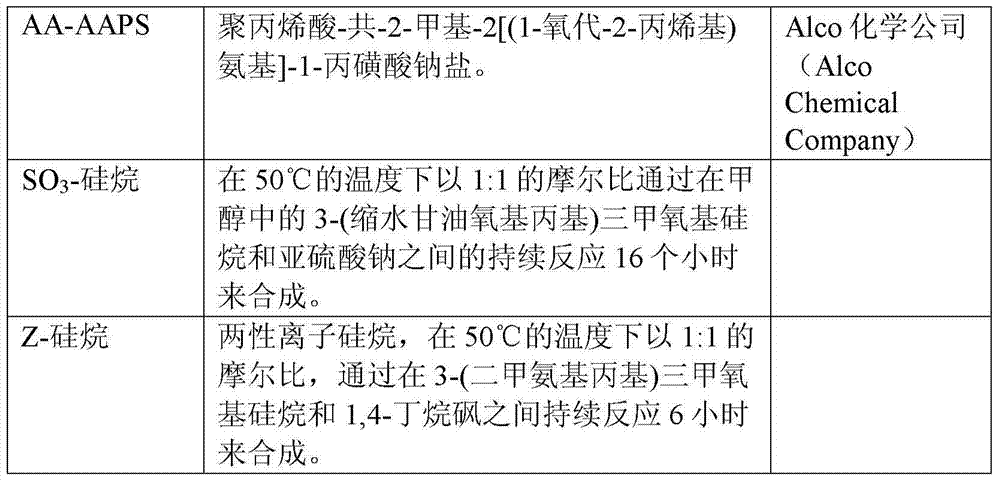

[0301] The following non-limiting examples are provided to further illustrate the compositions and methods provided herein. Unless indicated otherwise, the percentages are percentages by weight relative to the total mass of the composition and add up in each case to 100% by weight.

[0302] testing method :

[0303] Static Water Contact Angle Measurement [W.C.A.]

[0304] Static water contact angle measurements were performed on dried (treated) samples using deionized water available from Millipore Corporation. The contact angle analyzer used was a Video Contact Angle Analyzer available under the trade designation VCA Optima (AST Products Inc.). Static contact angles were measured on sessile droplets (1 μL) at 30 seconds after deposition. The reported values are the mean of at least 4 individual measurements.

[0305] Transmittance measurement :

[0306] Samples were tested for light transmission (T) and haze (H) using a BYK Gardner Haze-Gard Plus instrument (BYK ...

example 1 and example 2 and comparative example C-1 and comparative example C-2

[0337] In Examples 1 and 2, glass test panels were treated with 5% by weight aqueous dispersions of acidified SIL-3 containing various amounts of Z silane as given in Table 1 according to the general method. Comparative Example C-1 was made with a glass test panel treated with a 5 wt % aqueous dispersion of acidified SIL-3, while Comparative Example C-2 was made with a glass test panel treated with a 5 wt % aqueous dispersion of Z silane. Hard water stains were produced according to the methods outlined above. The test panels were evaluated for their transmittance. All test results are listed in Table 1.

[0338] Table 1

[0339] example

example 3 and comparative example C-3

[0341] Example 3 and Comparative Example C-3 were made in the same manner, except that different silica nanoparticles and different sulfonated silanes were used, as indicated in Table 2. The coating composition had a total solids content of 5% by weight. Hard water stains were produced according to the general method outlined above. The test panels were evaluated for their transmittance. The test results are listed in Table 2.

[0342] Table 2 : Evaluation of silica nanoparticles with sulfonated silanes.

[0343] example

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com