Flip-chip high-voltage LED chip and preparation method thereof

A technology of LED chips and chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of heat conduction and reliability of LED high-voltage chips that have not been solved, affect chip reliability, and difficult to export heat, and achieve good heat dissipation effect. , Guaranteed reliability, fast heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

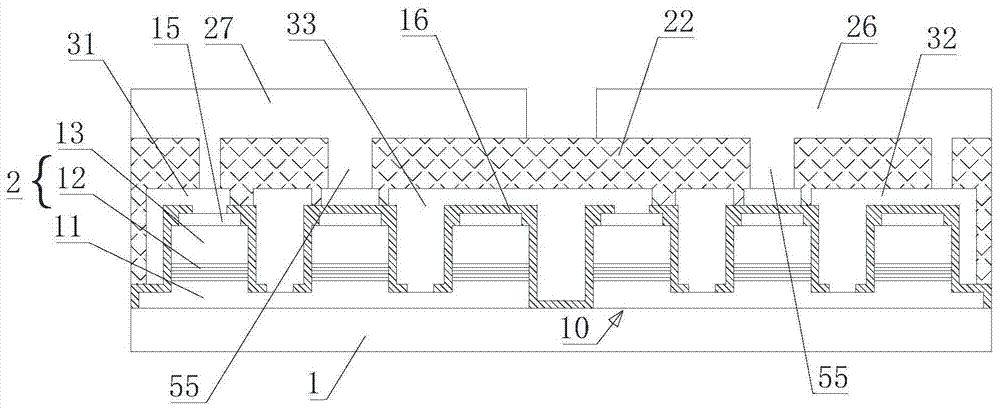

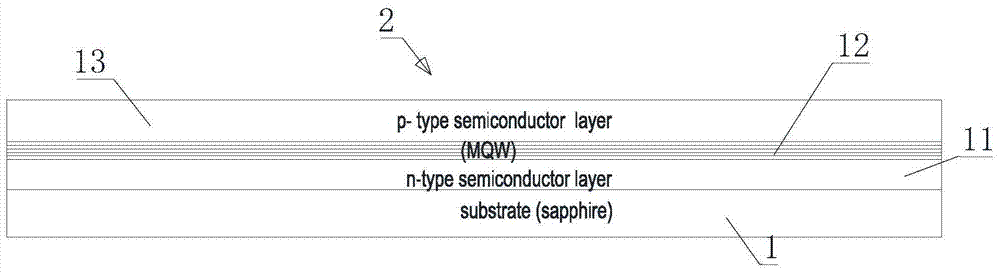

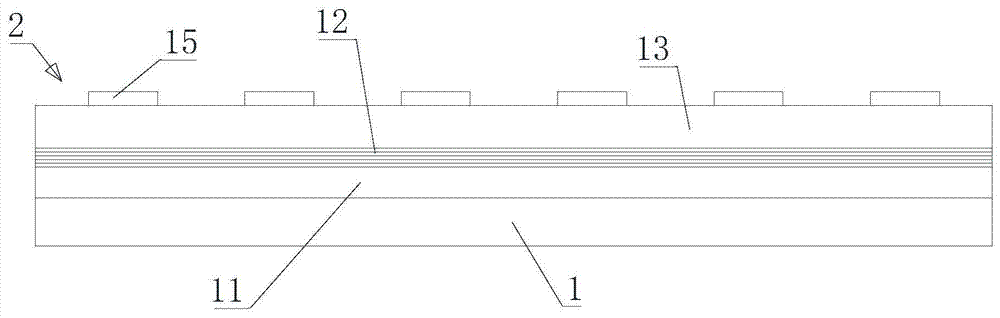

[0040] Such as figure 1 As shown, the flip-chip high-voltage LED chip of the present invention includes a substrate 1 and M chips 10 located on the surface of the substrate 1 that are insulated and independent from each other, M is an integer greater than or equal to 2, and each chip 10 includes 1 N-type gallium nitride layer 11, light-emitting layer 12 and P-type gallium nitride layer 13 on the surface, P-type gallium nitride layer 13 covered with reflective layer 15, N-type gallium nitride layer 11, light-emitting layer 12 and P-type gallium nitride layer 13 The GaN-type GaN layer 13 constitutes the epitaxial layer 2 of each chip. Each chip is separated by a trench 3 whose depth reaches the surface of the substrate 1 . The surface of the epitaxial layer 2 and the reflective layer 15 of each chip is covered with the first insulating layer 16 . On the first insulating layer 16, form the P lead electrode 31 electrically connected with the reflection layer 15 of the first chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com