Aluminum electrolysis cell with end face electricity outgoing

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of electrolytic cells, can solve the problems of large horizontal current, large cell spacing, and increased investment costs, and achieve the effects of stable electrolysis, small horizontal current, and reduced investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

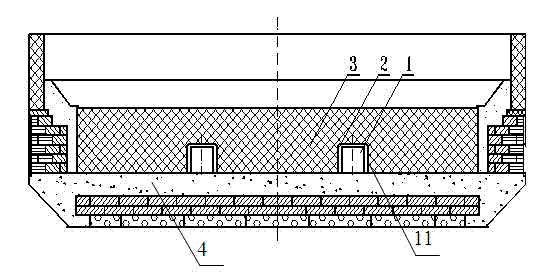

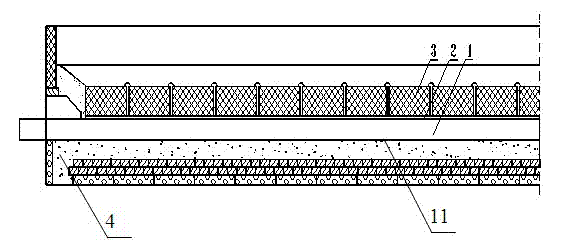

[0018] refer to figure 1 and figure 2 , the aluminum electrolytic cell with end face electricity discharge includes a cathode carbon block 1 and a cathode rod 2, a rod groove 11 is opened on the cathode carbon block 1, and a cathode rod 2 is arranged in the rod groove 11 along its length direction, and the cathode carbon block is fast 1 is set in the tank shell 4 of the electrolytic cell, and the rod groove 11 penetrates the tank shell 4 at the outlet end of the electrolytic cell, so that the electrolytic cell can directly discharge electricity from the outlet end, without the need to discharge electricity from the side and configure a large number of tank side busbars. The slotting direction of the rod groove 11 is parallel to the side of the electrolytic cell where the rod groove 11 is located, and the paste 3 is filled between the cathode rod 2 and the rod groove 11. The paste 3 mainly plays a role of fixing and conducting, and the cathode rod 1 can It is a steel rod or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com