Material for transfusion hose and application of material

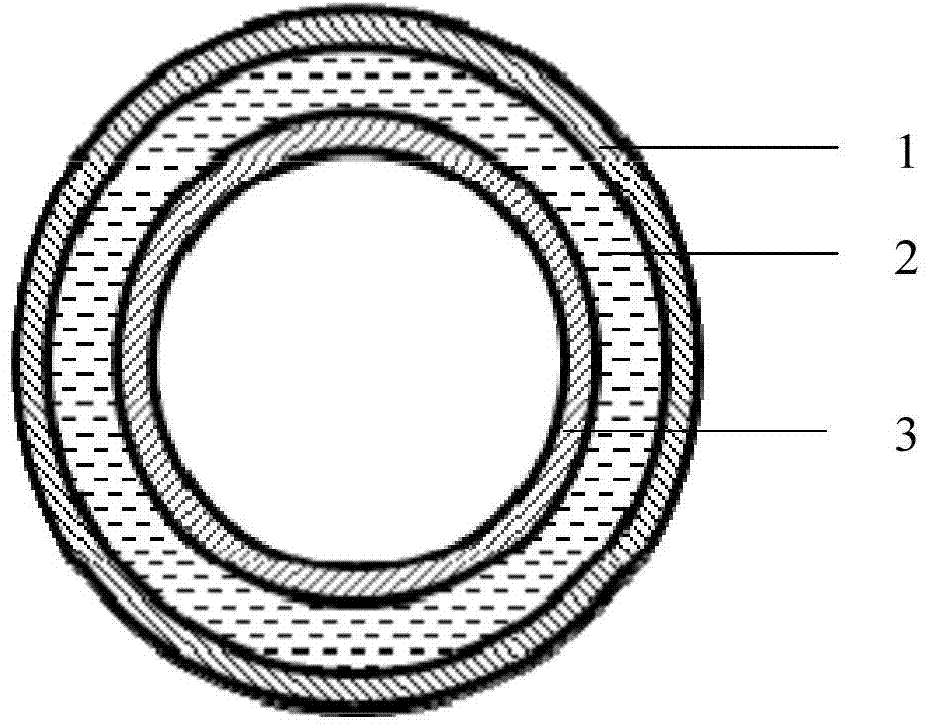

A technology for infusion hose and outer layer materials, applied in catheters, layered products, synthetic resin layered products, etc., can solve the problem of absorbing active ingredients of medicinal liquid, etc., and achieve benefits to human health, improved elasticity, and good welding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

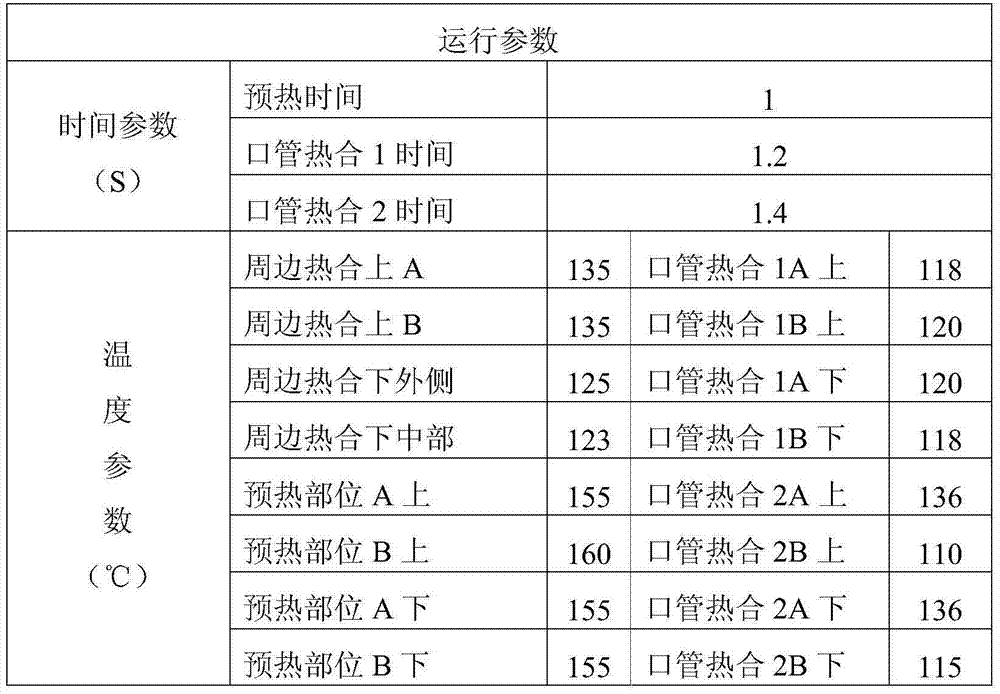

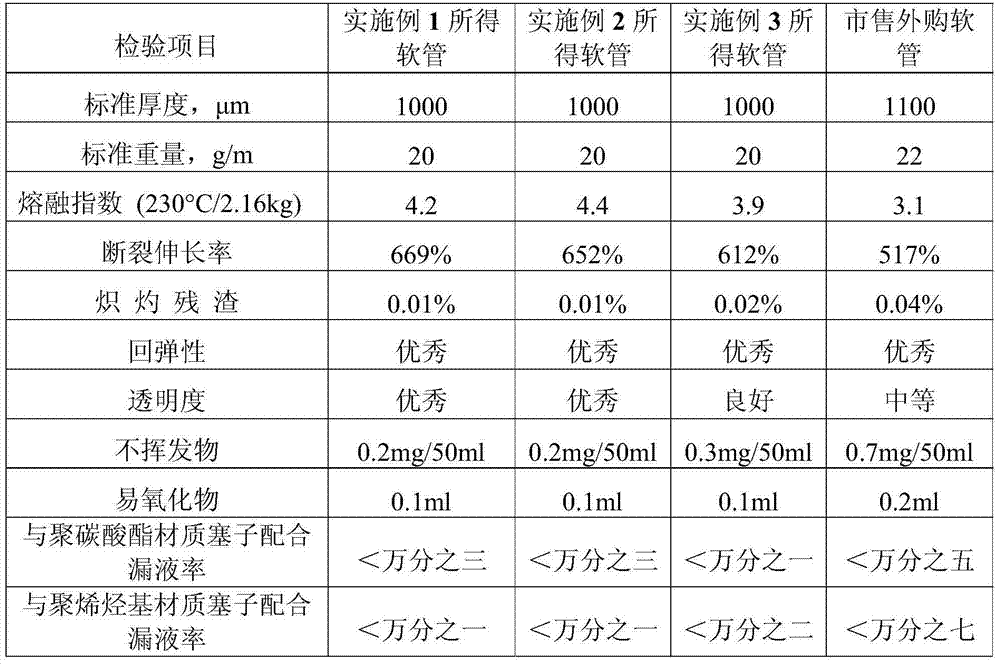

Examples

Embodiment 1

[0035] In the transfusion hose of this embodiment, the outer layer formula adopts 99% polypropylene (melting point 131.2°C, density 0.901g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 5.6g / 10min, the tensile strength is 19MPa, and the impact strength is 11KJ / m 2 ), and 1% by weight of styrene-ethylene-butylene-styrene (density 0.890g / cm 3 , under the test conditions of 230°C and 2.16Kg, the melt flow rate is 5.1g / 10min), add 0.07% of the weight percentage of the above-mentioned material 2,6-tert-butyl-4-methylphenol in a high-speed stirrer Physical mixing is carried out, and the mixed material can be used directly or after being granulated by twin-screw.

[0036] The middle layer formulation is 70% by weight of polypropylene (melting point is 156.1°C, density is 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 3.7g / 10min, the tensile strength is 15MPa, and the impact strength is 19KJ / m 2 ), and 30% by weight o...

Embodiment 2

[0042] In the transfusion hose of this embodiment, the outer layer formulation adopts 50% by weight polypropylene (melting point 131.2°C, density 0.901g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 5.6g / 10min, the tensile strength is 19MPa, and the impact strength is 11KJ / m 2 ), with 50% by weight of styrene-ethylene-butylene-styrene (density 0.890g / cm 3 , under the test conditions of 230°C and 2.16Kg, the melt flow rate is 5.1g / 10min), add 0.07% of the weight percentage of the above-mentioned material 2,6-tert-butyl-4-methylphenol in a high-speed stirrer Physical mixing is carried out, and the mixed material can be used directly or after being granulated by twin-screw.

[0043] The middle layer formulation is 70% by weight of polypropylene (melting point is 156.1°C, density is 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 3.7g / 10min, the tensile strength is 15MPa, and the impact strength is 19KJ / m 2 ), and...

Embodiment 3

[0049] In the transfusion hose of this embodiment, the outer layer formula adopts 70% by weight polypropylene (melting point 131.2 ℃, density 0.901g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 5.6g / 10min, the tensile strength is 19MPa, and the impact strength is 11KJ / m 2 ), and 30% by weight of styrene-ethylene-butylene-styrene (density 0.890g / cm 3 , under the test conditions of 230°C and 2.16Kg, the melt flow rate is 5.1g / 10min), add 0.07% of the weight percentage of the above-mentioned material 2,6-tert-butyl-4-methylphenol in a high-speed stirrer Physical mixing is carried out, and the mixed material can be used directly or after being granulated by twin-screw.

[0050] The middle layer formulation adopts 30% by weight polypropylene (melting point is 156.1°C, density is 0.891g / cm 3 , under the test conditions of 230°C and 2.16kg, the melt flow rate is 3.7g / 10min, the tensile strength is 15MPa, and the impact strength is 19KJ / m 2 ), and 70%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com