Intra-mould automatic material cutting head device

A cutting head and automatic technology, which is applied in the field of automatic cutting head device in the mold, can solve the problems of increasing the burden and operation of workers, and cannot meet the requirements of automation and mass production, so as to avoid manual cutting or hand tearing of the edge cutting head, Effects of reducing burden and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

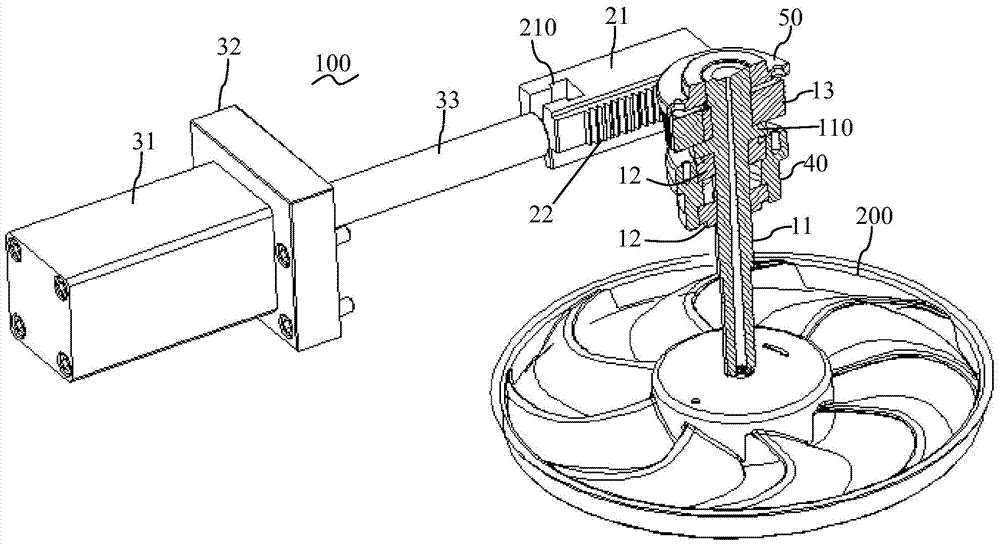

[0018] Such as figure 1 As shown, the automatic in-mold cutting head device 100 of the present invention includes: a cutting assembly, a transmission assembly, and a power assembly.

[0019] The material cutting assembly is used for automatic material cutting of the plastic part 200 , and it includes: a large nozzle nozzle 11 , a bearing 12 , and a gear 13 . Wherein, said Dashuikou nozzle 11 has an injection molding channel, and the two ends of the injection molding channel are inlet and outlet respectively, through which liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com