Stator welding machine

A welding machine and stator technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency, inability to achieve continuous welding, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

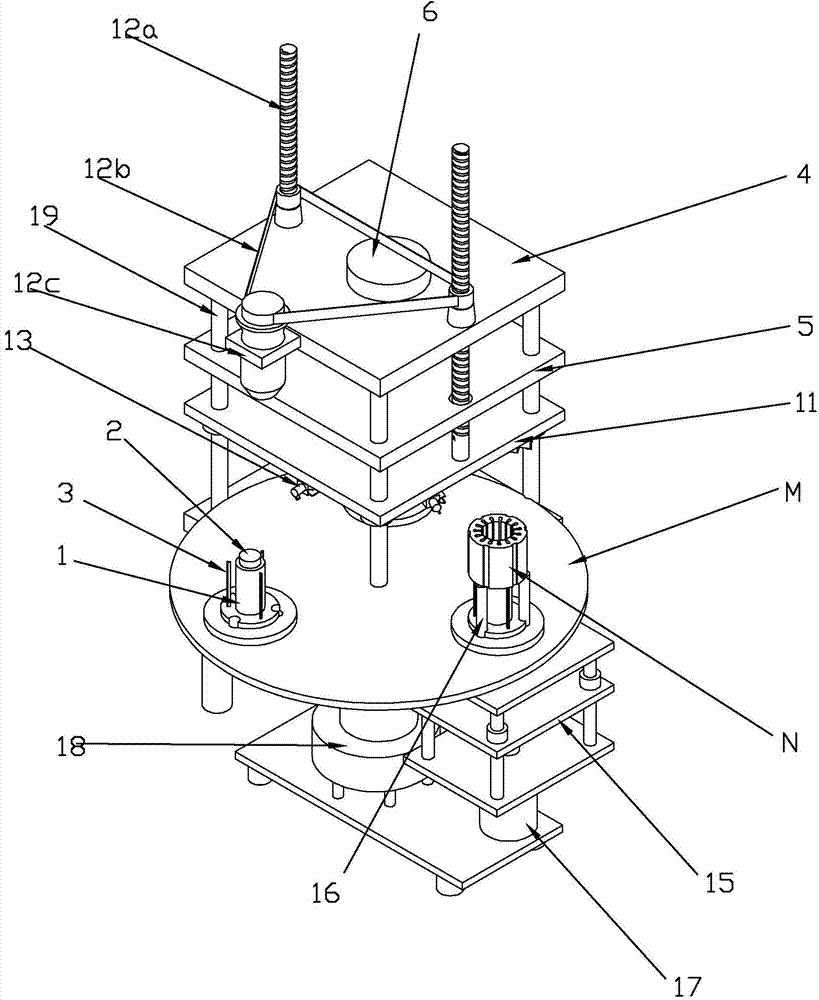

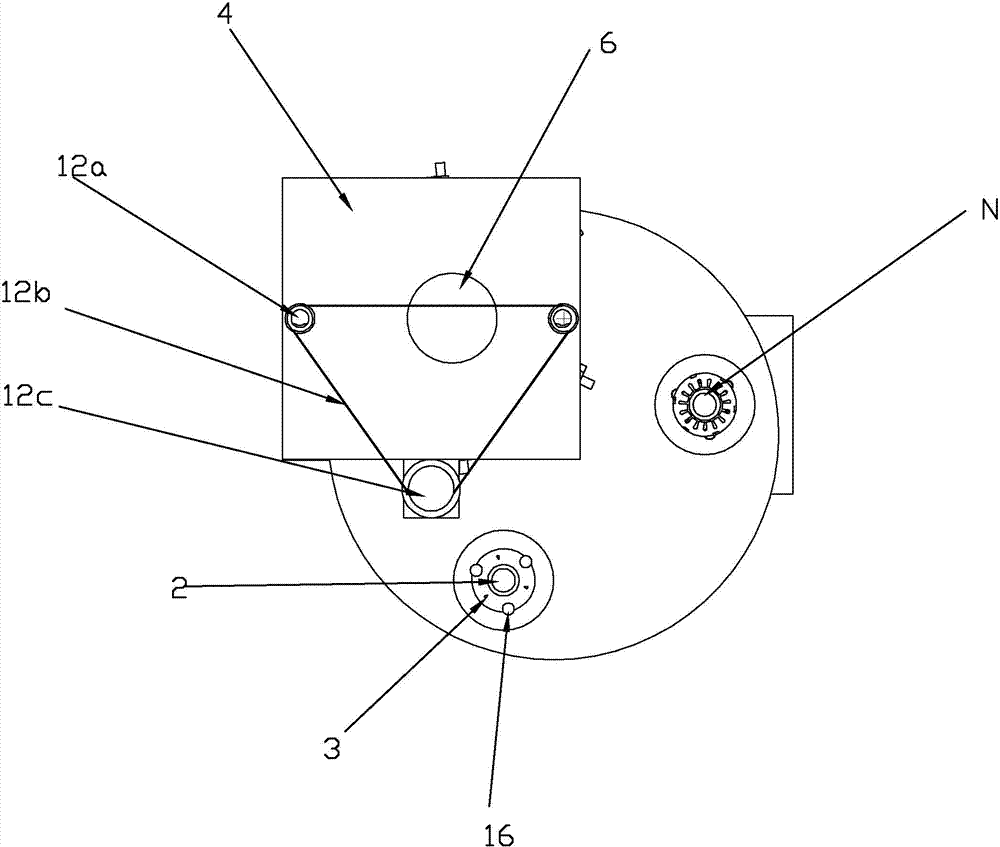

[0023] A stator welding machine, including a rotary table M with three stations controlled by a servo motor 18, the servo motor 18 is located below the rotary table M, and can be connected through gear transmission, belt transmission or the output shaft of the servo motor 18 Rotary table M. Each station is equipped with a stator tooling assembly, which is evenly distributed on the rotary table at an angle of 120 degrees. The stator tooling assembly includes an expansion sleeve 1, an expansion core 2 that cooperates with the expansion sleeve 1, and the expansion sleeve 1 is distributed in the circumferential direction. There are three restricting rods 3 restricting the rotation of the stator N, and the restricting rods 3 are inserted into the winding slots of the stator N. The three stations sequentially include a putting station, a welding station, and an ejecting station; the putting station is composed of a simple stator tooling assembly, which is used for workers to put in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com