Double disc opener coupling bionic disc structure

A ditch opener and double disc technology, applied in the direction of excavation/covering trenches, application, planting methods, etc., can solve the problems of increased traction resistance, increased soil disturbance, large working resistance, etc., and achieve the goal of reducing fuel consumption, reduce ditching resistance, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

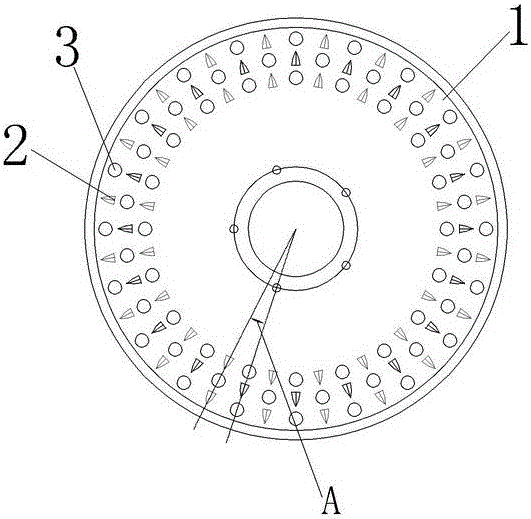

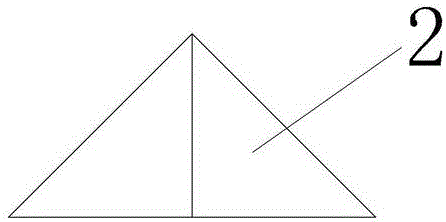

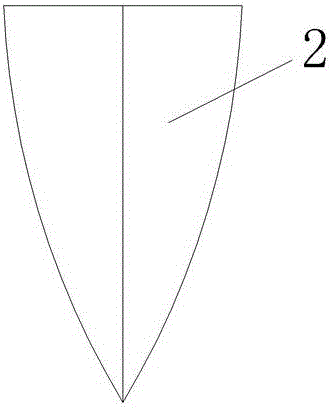

[0016] Such as figure 1 As shown, in this embodiment, wedge-shaped protrusions 2 and spherical convex hulls 3 are arranged on the surface of disc 1 of the double-disc opener. The embodiment has three layers in total, and the wedge-shaped protrusion 2 of the adjacent layer is opposite to the spherical convex hull 3; T is the thickness of the disc 1; as figure 2 , image 3 and Figure 4 As shown, H1 is the height of the wedge-shaped protrusion 2, and L1 is the length of the wedge-shaped protrusion 2: as Figure 5 As shown, H2 is the height of the spherical crown of the spherical convex hull 3, D2 is the diameter of the spherical crown of the spherical convex hull 3; A is the angle between a wedge-shaped protrusion 2 and a spherical convex hull 3 adjacent on the same ring along the radial direction ; Wherein H1=T, L1=D2, H2=7%~13%D2, A=7.2°~12°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com