Component taking and inserting device and fully-automatic inserting machine

A technology of plug-in devices and components, applied in the field of manipulators, can solve problems such as low work efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

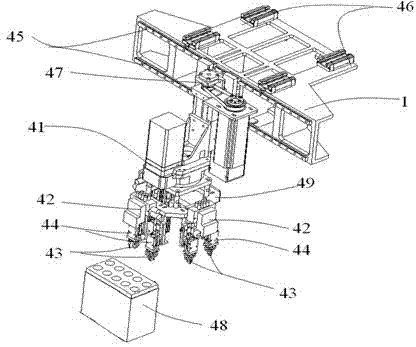

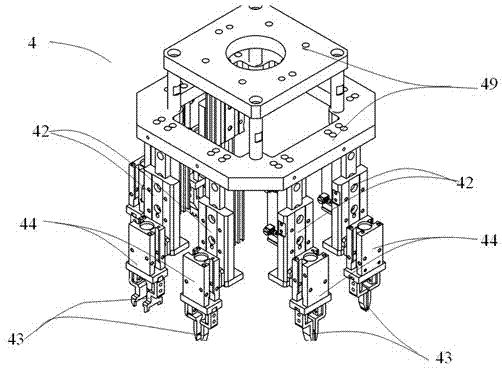

[0017] This embodiment provides a kind of take-up and plug-in device 4 for components, such as figure 1 , 2 , The retrieving plug-in device 4 is composed of a rotating head 41, an upper and lower cylinder 42, a jaw 43, a jaw fixed cylinder 44, a frame 49, an X-axis module 45, a Y-axis module 46 and a Z-axis module 47; wherein, The Z-axis module 47 is fixed on the X-axis module 45, the X-axis module 45 is fixed on the Y-axis module 46, one end of the rotating head 41 is fixed on the Z-axis module 47, and the other end is fixed on the frame 49. top, so that the rotating head 41 can move freely in the X, Y, Z directions, up, down, left, and right, front and rear directions, and it can rotate 360 degrees in all directions; On the cylinder 42, the jaws 43 are fixed on the jaw fixing cylinder 44, so when the rotating head is free or rotates in the up, down, left, and right directions along the X, Y, and Z directions, the jaws 43 can be simultaneously driven up and down along the...

Embodiment approach 2

[0019] This embodiment is a further improvement of Embodiment 1. The main improvement is that the plug-in device 4 for taking materials in Embodiment 1 cannot automatically replace the jaws 43. When the jaws 43 need to be replaced, they need to be replaced manually after stopping work. The retrieving plug-in device 4 in this embodiment has a jaw storehouse 48. When the reclaiming plug-in device 4 needs to replace the jaws 43 according to the site conditions, the original jaws can be directly placed in the jaw storehouse 48 without stopping the machine. The required jaws are automatically installed on the jaw fixing cylinder 44 to complete the replacement, and the types of jaws in the jaw library 48 can be arbitrarily increased or decreased according to the types of components required on the PCB board to be inserted, so that the entire retrieving plug-in device 4 More automatic and intelligent.

[0020] Apart from this, this embodiment is completely the same as Embodiment 1, a...

Embodiment approach 3

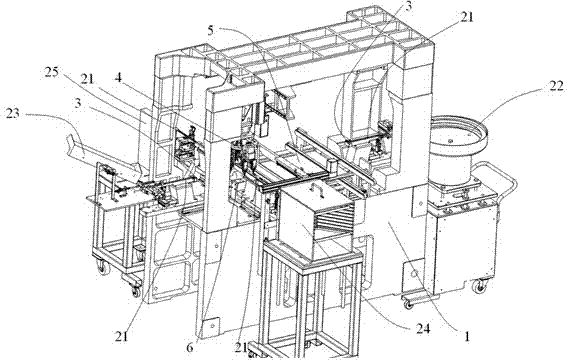

[0022] This embodiment provides a fully automatic plug-in machine, such as image 3 and Figure 4 As shown, it is composed of a base 1, a component supply device with a feeding tray and a material delivery trough 21, an electrode determination device 3, a retrieving plug-in device 4, a PCB board transmission and fixing device 5, and a component positioning device 6. It is worth mentioning that What is more, the plug-in machine in this embodiment can use one or more component supply devices of the same or different structures at the same time to adapt to one or more components of the same or different types. Correspondingly, the plug-in device 4 The clamping jaw 43 and the electrode determining device 3 can also be one or more. In this embodiment, four kinds of component supply devices are set, which are respectively located on the left side, the right side, the front side and the rear side of the base, and the left side is the component supply device for braiding material. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com