Bearing bush type conductive clutch

A technology for clutches and bushings, which is applied in the field of bushing-type conductive clutches, can solve the problems of high manufacturing costs of conductive clutches, affecting the smooth operation of equipment, and hot conductive clutch plates, etc., and achieves the advantages of increased working thickness, reduced manufacturing costs, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The bush type conductive clutch device provided by the present invention will be further described below in conjunction with the accompanying drawings.

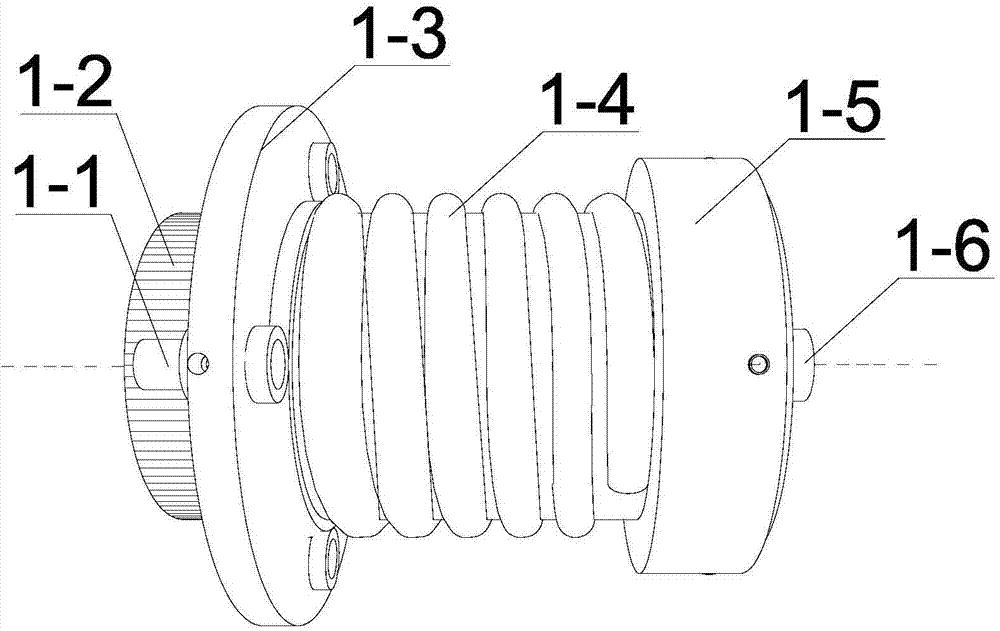

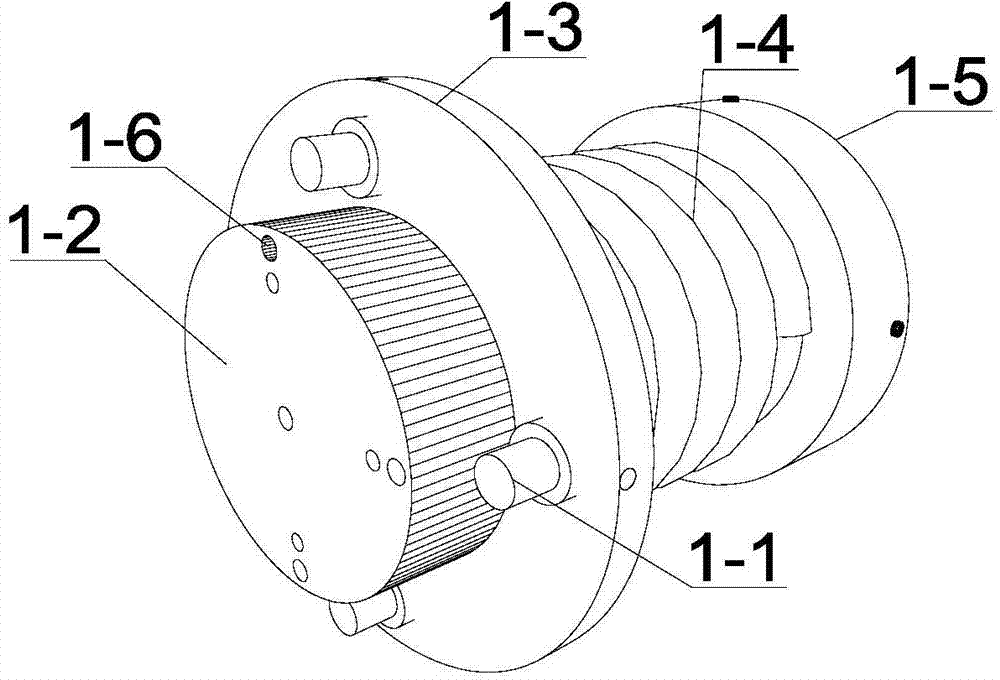

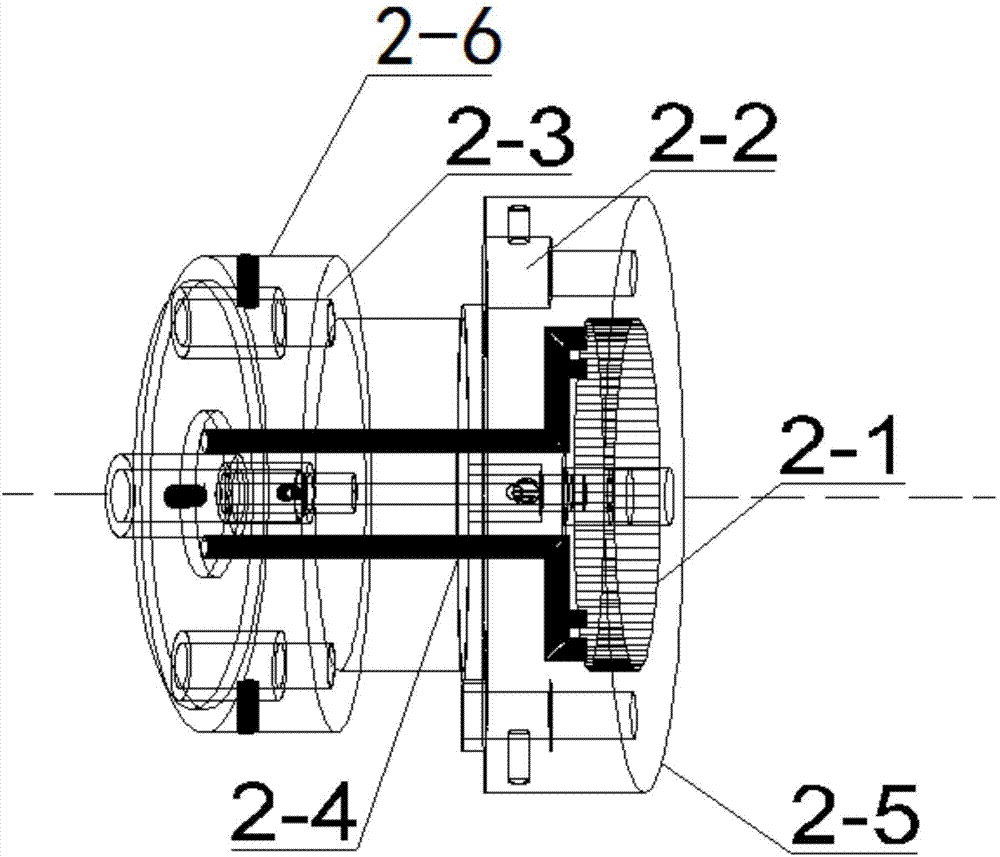

[0025] Such as figure 1 As shown, it is a schematic diagram of a sub-conductive clutch, figure 2 It is a schematic diagram of the isometric structure of the sub-conductive clutch body. It can be seen that the sub-conductive clutch body includes a fixed bolt 1-1, a push-type conductive clutch plate protrusion 1-2, a sub-conductive clutch body flange 1-3, and a return spring 1-4, spring base 1-5 and cable 1-6; among them, the push-type conductive clutch boss 1-2, the sub-conductive clutch flange 1-3, the return spring 1-4, and the spring base 1-5 Coaxial setting, the sub-conductive clutch flange 1-3 and the spring base 1-5 are respectively arranged at both ends of the sub-conductive clutch, and the return spring 1-4 is arranged on the sub-conductive clutch flange 1-3 and the spring Between the base 1-5, the push-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com