A Jumper Flying Spot Scanning Device Used in X-ray Backscatter Imaging System

An imaging system, flying point scanning technology, applied in the direction of measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of insufficient rigidity of the scanning drum, X-ray leakage, and inability to install, etc., to reduce leakage Effects of dose rate, increased occlusion ability, and reduced background value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

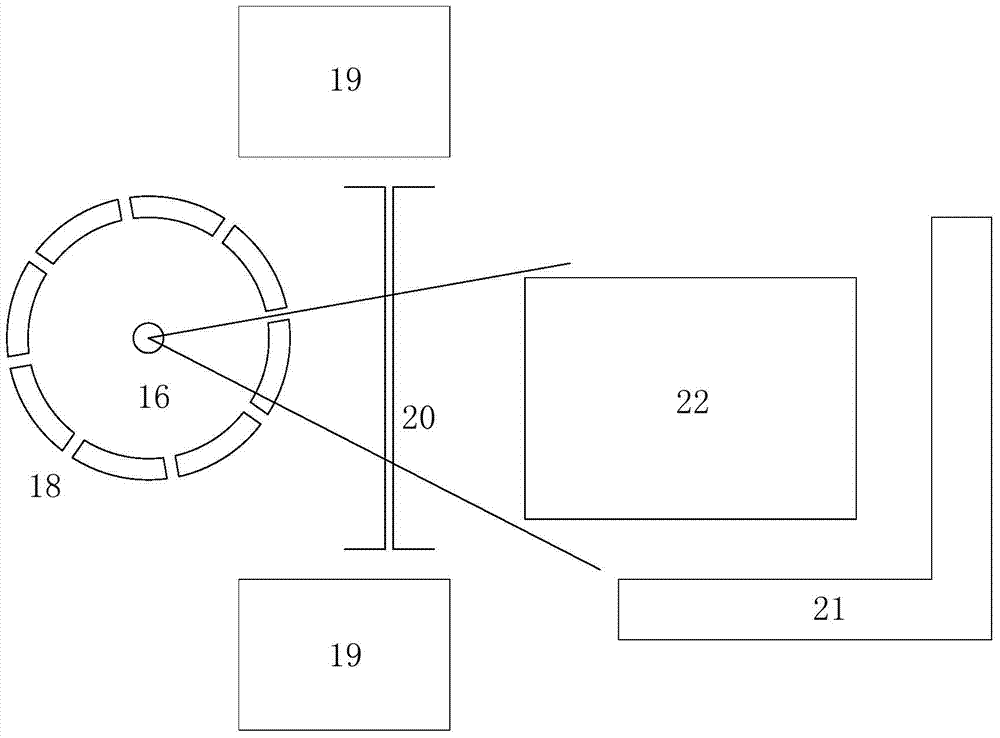

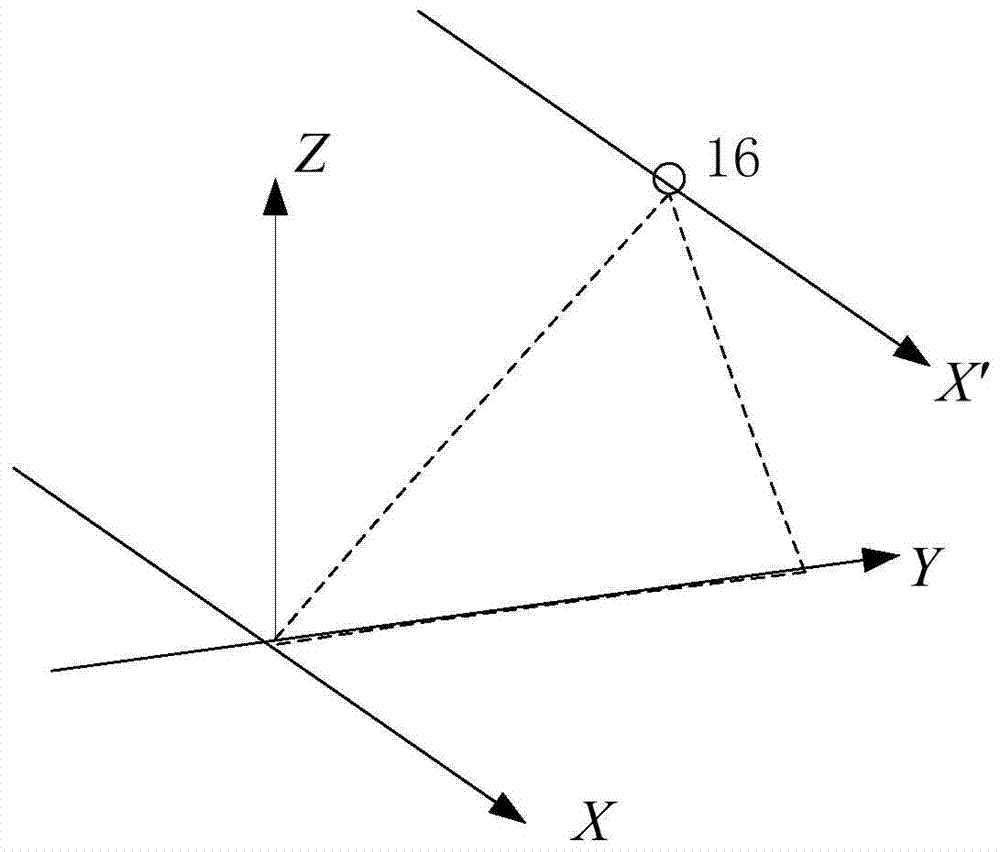

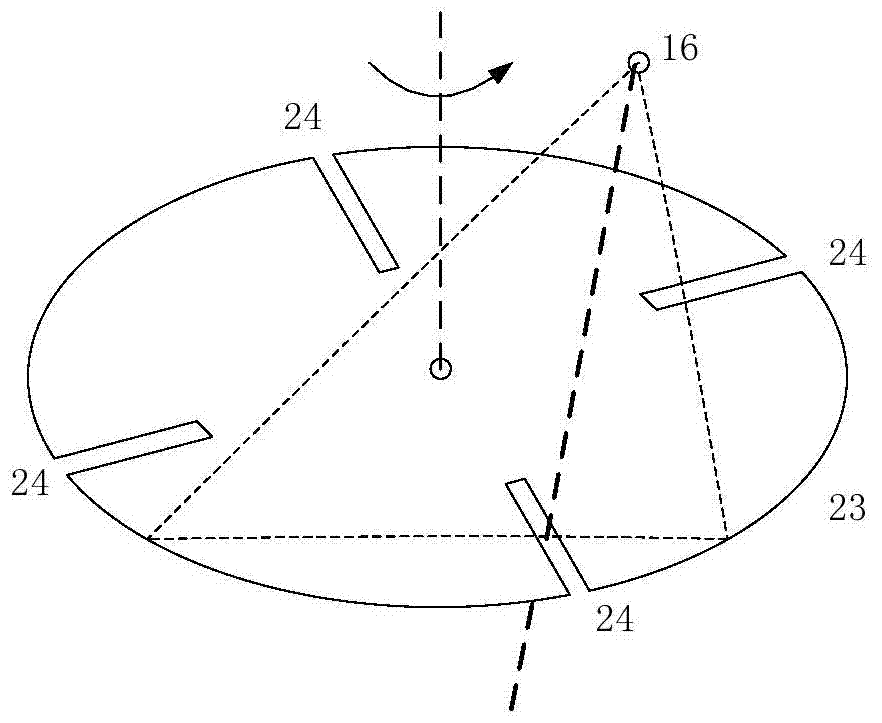

[0044] Such as Figure 9 A jumper flying spot scanning device for an X-ray backscatter imaging system is shown, including a ray source 16 located in the X-ray machine 1, and an incident collimator connecting the X-ray machine 1 and the scanner outer cylinder 4 2. The scanning drum 7 fixed in the outer cylinder 4 of the scanner through the rotating shafts 8 at both ends, and the exit collimator 3 connected with the outer drum 4 of the scanner, is characterized in that: the scanning drum 7 A number of discontinuous incident slit sections 11 and exit slit sections 12 are engraved on the side wall, which can be formed by one incident slit section 11 and one exit slit section 12 at any time when the scanning drum 7 rotates. The only scanning collimation hole. The outer cylinder 4 of the scanner is a hollow steel cylinder with uniform wall thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com