Synthesis process for ethoxy carbonyl isothiocyanate

A technology of ethoxycarbonyl isothiocyanate and synthesis process, which is applied in the field of ethoxycarbonyl isothiocyanate synthesis process, can solve the problems of serious environmental pollution and high production cost, and reduce environmental pollution and consumption , the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

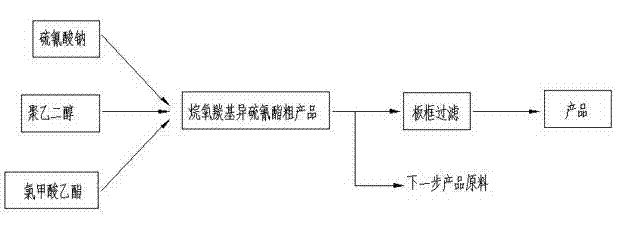

Image

Examples

Embodiment 1

[0010] In the ethoxycarbonyl isothiocyanate synthesis process of the present invention, 45 parts of sodium thiocyanate with a purity of 99% are dissolved in 80 parts of water, and 0.55 parts of polyethylene glycol with an average molecular weight of 200 are added to the solution. Diol, the temperature of the solution is lowered to below 10°C, and 54.8 parts of ethyl chloroformate with a purity of 99% are slowly added to the reaction system under stirring. The reaction temperature does not exceed 15°C, and the reaction is stirred for 3 hours. After the reaction, add 30 parts of water, stir for 10 minutes, and stand for 1 hour to separate the lower water phase. The upper oily liquid is N-ethoxycarbonyl isothiocyanate Ester, the product yield based on ethyl chloroformate is 83.42%, utilize this catalytic synthetic route to synthesize a series of products of alkoxycarbonyl isothiocyanate and carry out the next step of synthesizing alkoxy with the product synthesized by this synthet...

Embodiment 2

[0012] In the synthesis process of ethoxycarbonyl isothiocyanate of the present invention, 45 parts of sodium thiocyanate with a purity of 99% are dissolved in 80 parts of water, and 0.55 parts of polyethylene with an average molecular weight of 400 are added to the solution. Diol, the temperature of the solution is lowered to below 10°C, and 54.8 parts of ethyl chloroformate with a purity of 99% are slowly added to the reaction system under stirring. The reaction temperature does not exceed 15°C, and the reaction is stirred for 3 hours. After the reaction, add 30 parts of water, stir for 10 minutes, and stand for 1 hour to separate the lower water phase. The upper oily liquid is N-ethoxycarbonyl isothiocyanate Ester, the product yield based on ethyl chloroformate is 83.42%, utilize this catalytic synthetic route to synthesize a series of products of alkoxycarbonyl isothiocyanate and carry out the next step of synthesizing alkoxy with the product synthesized by this synthetic r...

Embodiment 3

[0014] In the ethoxycarbonyl isothiocyanate synthesis process of the present invention, 45 parts of sodium thiocyanate with a purity of 99% are dissolved in 80 parts of water, and 0.55 parts of polyethylene glycol with an average molecular weight of 600 are added to the solution. Diol, the temperature of the solution is lowered to below 10°C, and 54.8 parts of ethyl chloroformate with a purity of 99% are slowly added to the reaction system under stirring. The reaction temperature does not exceed 15°C, and the reaction is stirred for 3 hours. After the reaction, add 30 parts of water, stir for 10 minutes, and stand for 1 hour to separate the lower water phase. The upper oily liquid is N-ethoxycarbonyl isothiocyanate Ester, the product yield based on ethyl chloroformate is 83.42%, utilize this catalytic synthetic route to synthesize a series of products of alkoxycarbonyl isothiocyanate and carry out the next step of synthetic alkoxy with the product synthesized by this synthetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com