Wheel component

A technology of wheel components and hubs, which is applied to vehicle parts, rims, transportation and packaging, etc. It can solve problems such as tire detachment, anti-detachment breakage, impact on fuel consumption, etc., to solve the problem of tire installation, increase rotational friction, The effect of preventing tire leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

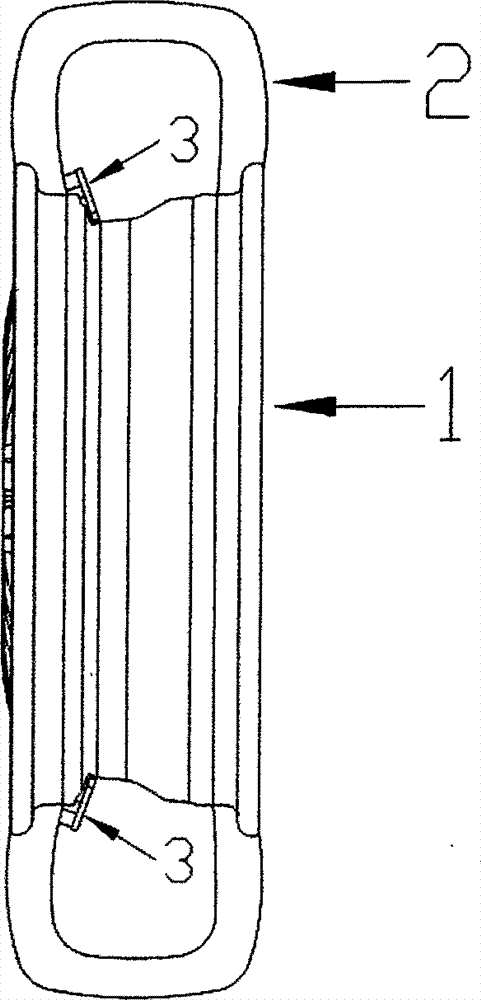

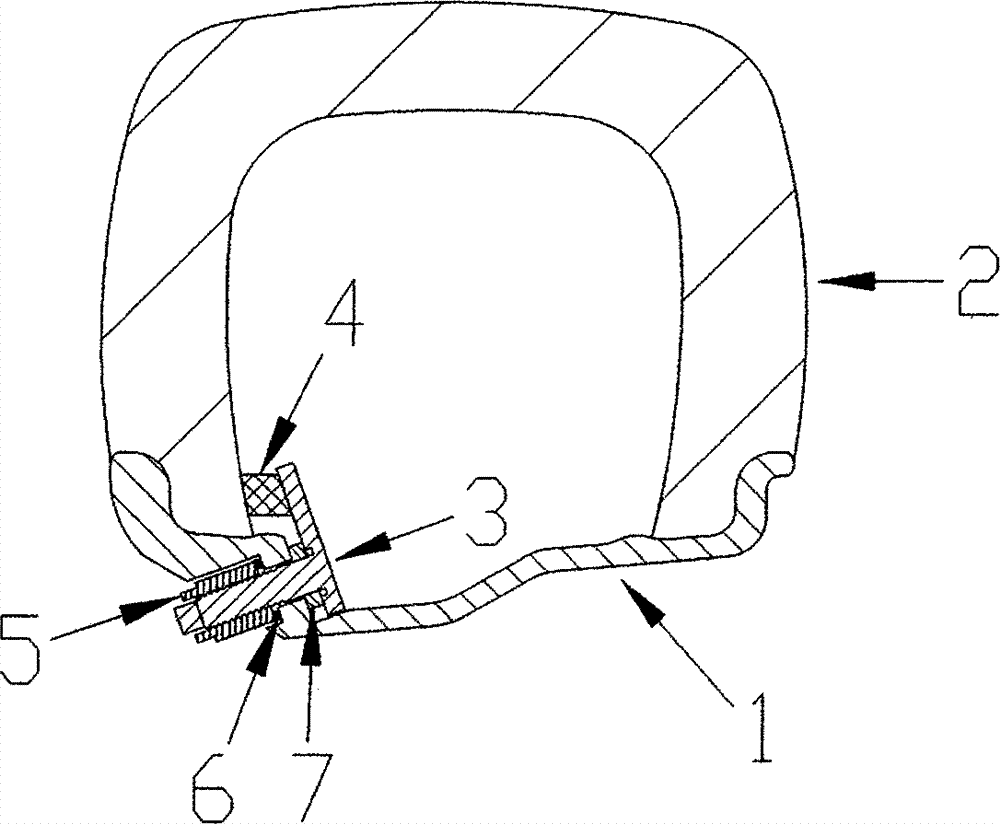

[0039] This embodiment provides a wheel assembly. like Figure 1-Figure 11 As shown, the wheel assembly includes an integral wheel hub 1 , a tire bead movable block 3 , a valve 12 , and a tire 2 . In addition to the round hole assembled with the valve 12, the integral wheel hub 1 also includes at least one round hole structure 14. There is a stop surface 15 around the round hole structure 14, and there is a hole at the intersection of the round hole structure 14 and the outer surface of the integral hub 1. The platform structure 13; the movable block 3 includes a rotating shaft 17 and a blocking plate structure 16, the blocking plate structure 16 is a cam structure, the rotating shaft 17 is located on one surface of the blocking plate structure 16, and the surface of the rotating shaft 17 has a threaded structure 18 , one end face of the rotating shaft 17 is a non-circular end face 19, and there is a groove structure 20 at the intersection of the rotating shaft 17 and the sto...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that a tire bead movable block 3 is installed in at least one circular hole structure 14 on the side wall of the wheel groove 9 inside the two integral wheel hubs 1 rim bead seats, as Figure 12 .

Embodiment 3

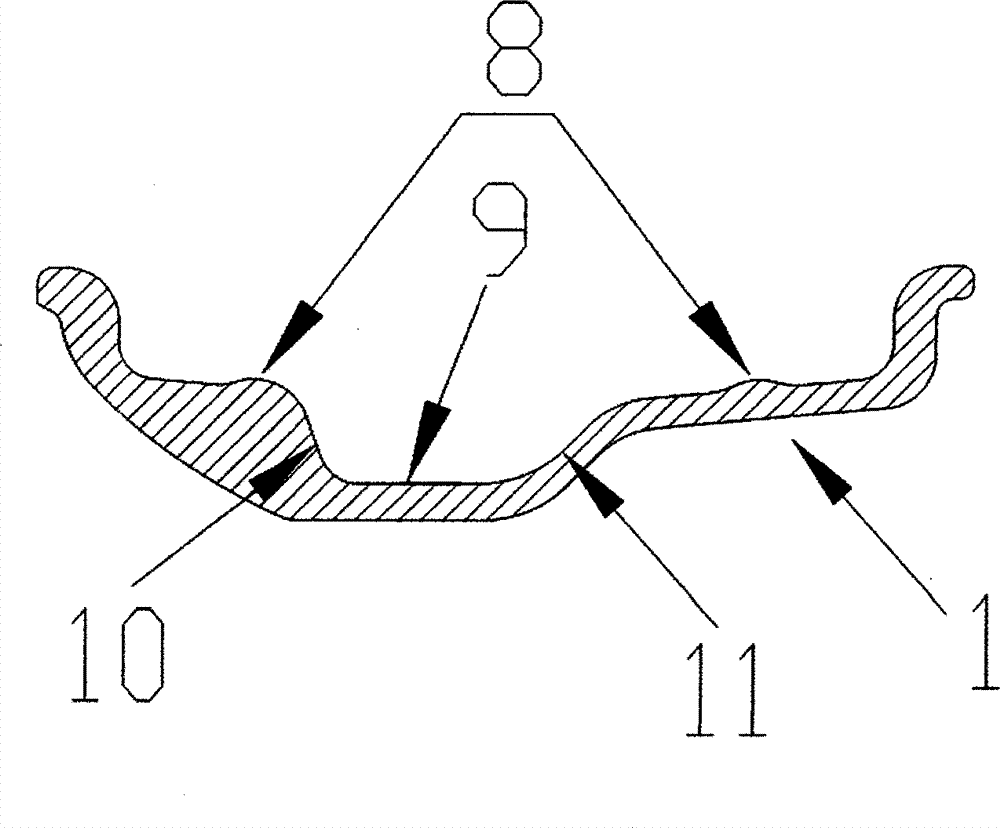

[0048] The difference between this embodiment and embodiment 1 is that the movable stopper 3 of the tire bead is in such as Figure 13 The position of a, by rotating clockwise to make the baffle structure 16 higher than the integral hub 1 rim bead seat protrusion 8 and not higher than the maximum shape of the hub (such as Figure 13 In b), block the tire bead 2 from sliding into the hub wheel groove 9.

[0049] See picture as Figure 13 In b, when the tire is low-pressure or zero-pressure and rotates counterclockwise, the stop surface 9 can prevent the tire bead movable block 3 from rotating clockwise again; Integral hub 1 appears to slide clockwise.

[0050] Or, in the circular hole structure adjacent to the same integral hub 1, tire bead movable stoppers 3 with the above two functions are alternately installed, thereby preventing the tire 2 from clockwise or counterclockwise with respect to the integral hub 1. slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com