Sand sieving method and device

A technology for screening sand and sand particles, applied in the field of sand screening methods and sand screening devices, can solve the problems of large energy consumption, clumped sand particles, unfavorable screening, etc., and achieves kinetic energy saving, good effect, and easy replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

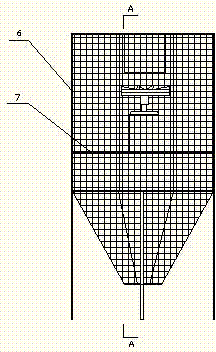

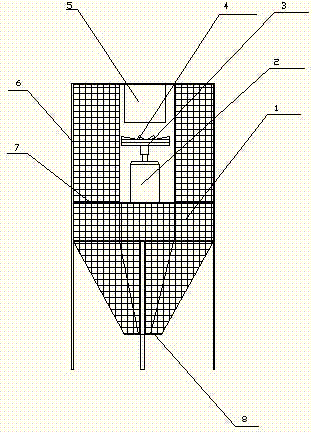

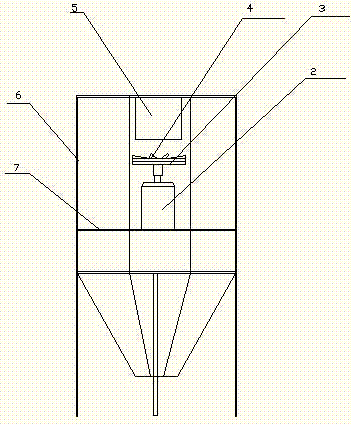

[0032] As shown in the attached figure: a sand screening device, including a filtering part and a driving part.

[0033] The filter part includes: screen 1, sand inlet 5, gravel outlet 8, support frame 6, the upper part of the support frame 6 is in the shape of a garden cylinder, and the lower part is conical, and the screen cloth 1 is fixedly attached to the support frame 6 , The sand inlet 5 is located at the upper end of the supporting frame 6, and the gravel outlet 8 is located at the lower end of the supporting frame 6.

[0034] Described driving part comprises: motor 2, impeller 3, blade 4, motor fixed frame 7, and motor 2 is fixed on the motor fixed frame 7, and impeller 3 is installed on the upper end of motor 2, and blade 4 is fixed on the impeller 3. The impeller 3 faces upwards.

[0035] The driving part is installed inside the filtering part, and the impeller 3 is located directly below the sand inlet 5 .

[0036] Motor fixing frame 7 is fixed on the middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com