Constant power output circuit and ultrasonic tooth cleaner constant power control method

A constant power, output circuit technology, applied in the electrical field, can solve problems such as output power fluctuations, achieve the effects of solving output power fluctuations, good cleaning effect, and improving adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

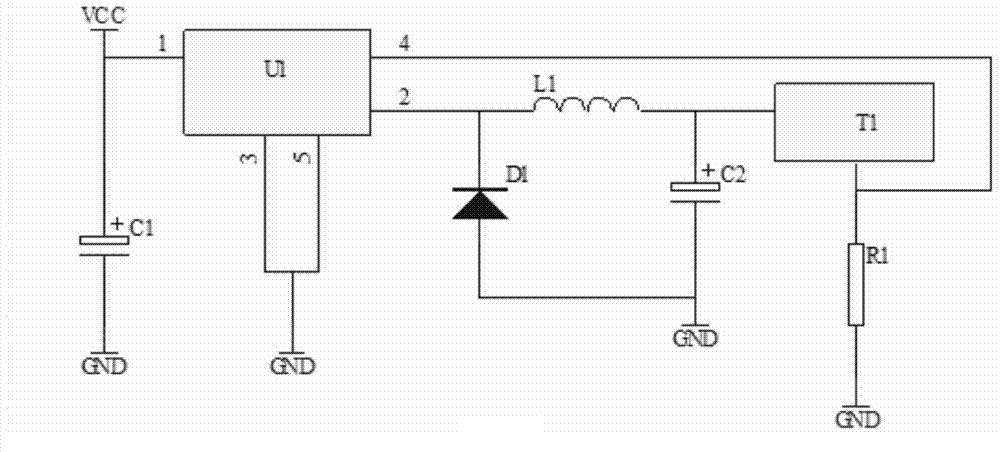

[0018] Embodiment 1, a kind of constant power output circuit, will combine below figure 1 A constant power output circuit provided in this embodiment will be described in detail.

[0019] Such as figure 1 As shown, a constant power output circuit diagram, including power output circuit, sampling resistor R1 and ultrasonic transformer T1.

[0020] The power output circuit includes a voltage stabilizing chip U1 and an inductor L1, the No. 1 pin of the voltage stabilizing chip U1 is connected to an external power supply, and the No. 2 pin of the voltage stabilizing chip U1 is connected to the ultrasonic transformer T1 through the inductor L1 The input terminal, No. 3 pins and No. 5 pins of the voltage stabilizing chip are respectively connected to the ground, No. 4 pins of the voltage stabilizing chip are grounded through the sampling resistor R1, and the output terminal of the ultrasonic transformer T1 is connected to the ground through the sampling resistor R1 is grounded.

...

Embodiment 2

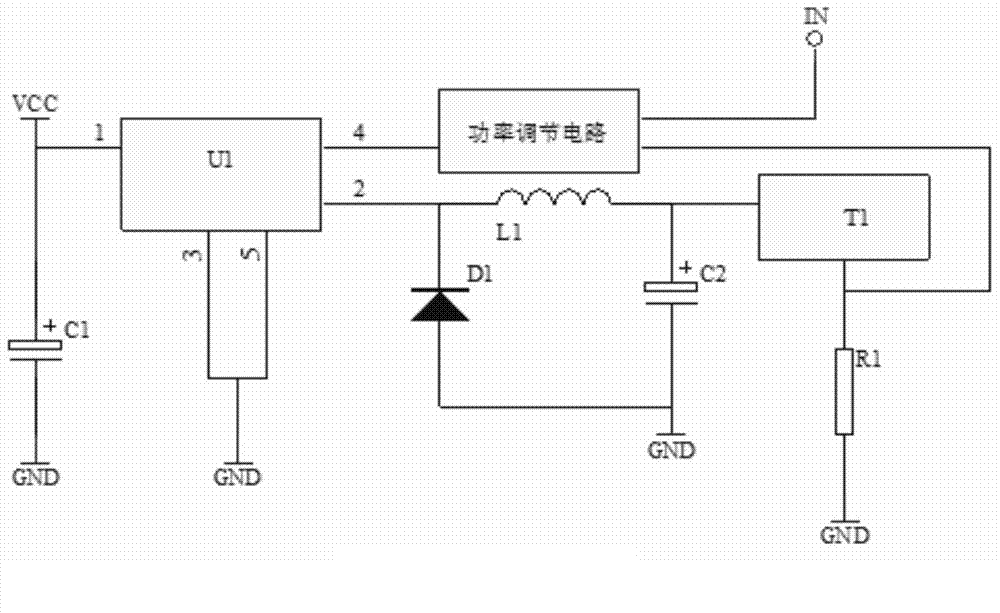

[0029] Embodiment 2, a constant power control method of an ultrasonic dental scaler, will be combined below figure 2 A method for controlling constant power of an ultrasonic dental scaler provided in this embodiment will be described in detail.

[0030] A constant power control method of an ultrasonic dental scaler, comprising:

[0031] Step 1: the voltage stabilizing chip U1 in the power output circuit provides power for the ultrasonic transformer T1 through the inductor L1;

[0032] Step 2: The ultrasonic transformer T1 adjusts the feedback voltage at its output terminal according to the input voltage provided by the power supply output circuit;

[0033] Step 3: The sampling resistor R1 acquires the feedback voltage at the output terminal of the ultrasonic transformer T1 and feeds it back to the voltage feedback terminal of the voltage stabilizing chip U1 in the output circuit of the power supply;

[0034] Step 4: The voltage stabilizing chip U1 in the power output circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com