Method for manufacturing sealing device, and sealing device

A sealing device and manufacturing method technology, applied in the direction of engine sealing, engine components, household components, etc., can solve the problem of easy to increase sliding resistance, difficulty in identifying the position of the ring-shaped convex part, and difficulty in improving the position accuracy of cutting, etc. problem, achieve the effect of reducing the effect, improving the sliding property, and suppressing the breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] refer to Figure 1 to Figure 10 The sealing device and its manufacturing method according to Example 1 of the present invention will be described. The sealing device of this embodiment can be preferably used as a hydraulic seal for reciprocating transmission systems such as AT and CVT of automobiles. In addition, it can also be used as a seal for reciprocating motion of general industrial machines such as construction machines and agricultural machines.

[0037] (Sealing means)

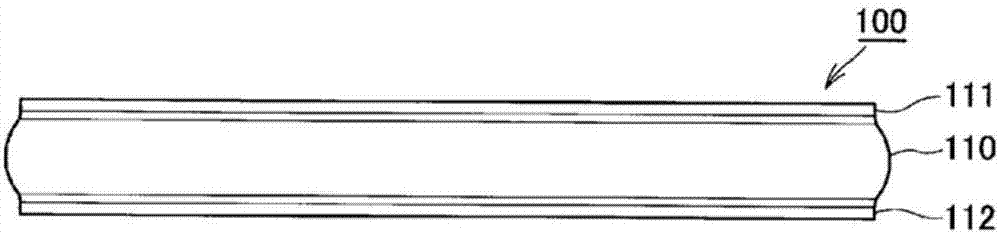

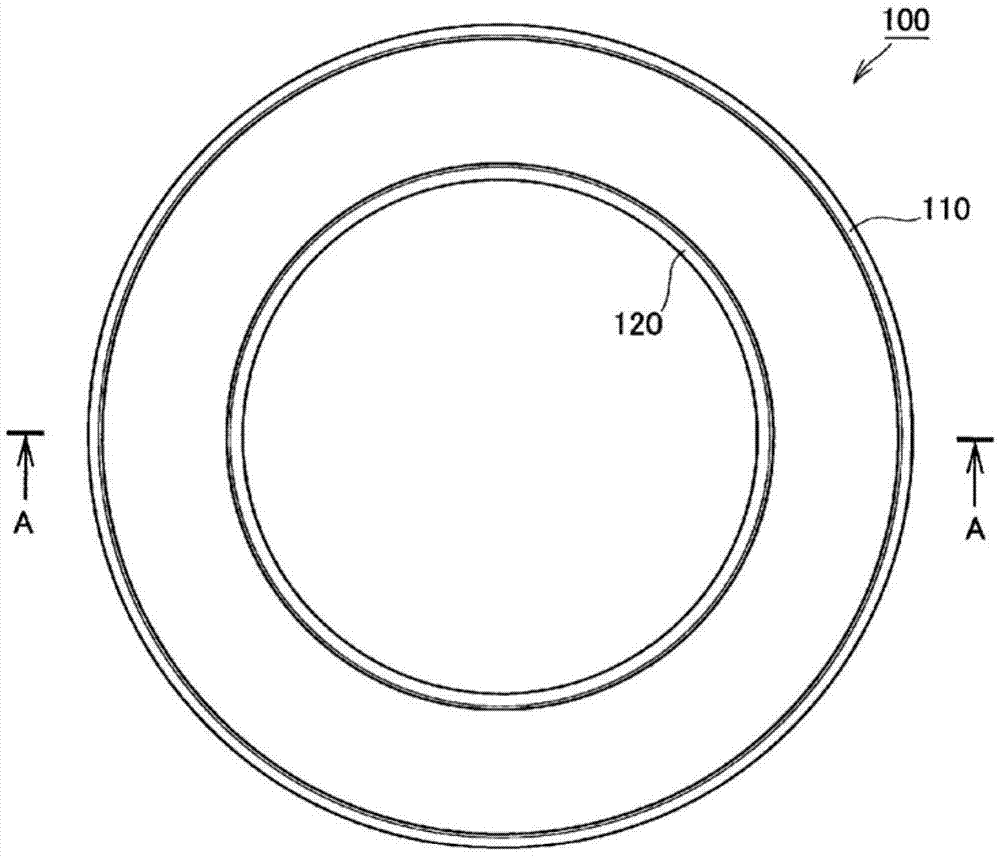

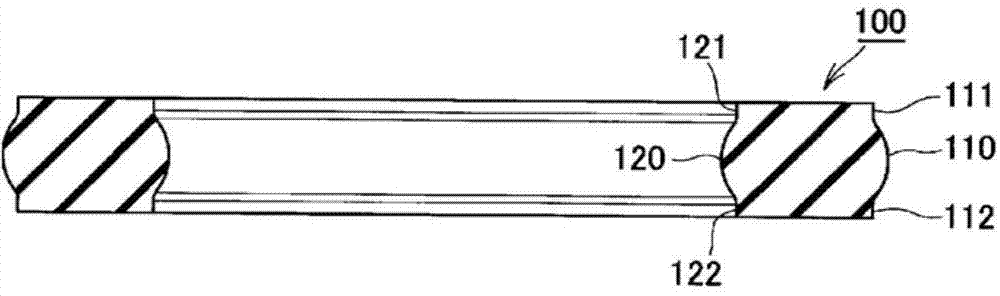

[0038] refer to Figure 1 ~ Figure 3 The sealing device of Example 1 of the present invention will be described. figure 1 is a side view of the sealing device of Embodiment 1 of the present invention, figure 2 is a plan view of the sealing device of Embodiment 1 of the present invention, image 3 is a cross-sectional view of the sealing device of Embodiment 1 of the present invention ( figure 2 A-A sectional view in).

[0039] The sealing device 100 of this embodiment is an annular mem...

Embodiment 2

[0069] Figure 11 Example 2 of the present invention is shown. In the above-mentioned first embodiment, the protruding heights of the outer peripheral convex part and the inner peripheral convex part of the sealing device are set to be equal, but in this embodiment, the protruding height of the outer peripheral convex part of the sealing device is set to be higher than that of the inner peripheral convex part. Structures when the protruding height is high.

[0070] The other structures and functions are the same as those in Embodiment 1, and the same components are given the same reference numerals, and their descriptions are appropriately omitted here. In addition, the method of manufacturing the sealing device is also the same as in the case of the above-mentioned first embodiment, and therefore its description is omitted.

[0071] Figure 11It is a schematic sectional view showing the state in which the sealing device according to the second embodiment of the present inv...

Embodiment 3

[0077] Figure 12 Example 3 of the present invention is shown. In the first embodiment described above, the protruding heights of the outer peripheral convex portion and the inner peripheral convex portion of the sealing device are equal, but in this embodiment, the protruding height of the inner peripheral convex portion of the sealing device is set to be higher than that of the outer peripheral convex portion. The structure of the case that stands out for height.

[0078] Since other structures and functions are the same as those in Embodiment 1, the same reference numerals are assigned to the same structural parts, and their descriptions are appropriately omitted. In addition, the manufacturing method of the sealing device is the same as that of the above-mentioned Example 1 except that the molded body is held by the middle mold instead of the outer mold at the time of demolding, so the description thereof is appropriately omitted.

[0079] Figure 12 It is a schematic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com