Device and method for determining multiscale porous characteristics of carbonatite

A carbonatite, multi-scale technology, applied in image data processing, instrumentation, calculation, etc., can solve the problems of high technical level experience dependence, casting thin sections affecting identification results, and differences in analysis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

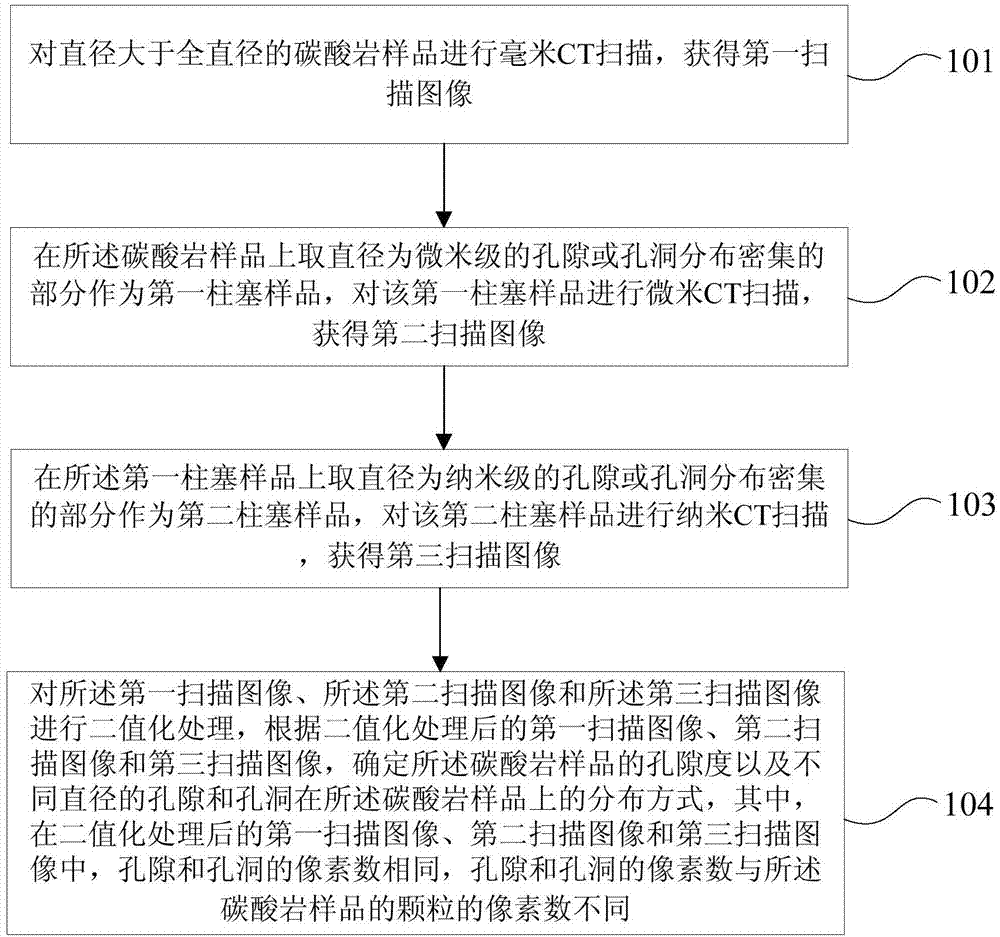

[0031] In the embodiment of the present invention, a method for determining the multi-scale pore characteristics of carbonatite is provided, such as figure 1 As shown, the method includes:

[0032] Step 101: Carrying out millimeter CT scanning on a carbonatite sample whose diameter is larger than the full diameter, and obtaining a first scanning image;

[0033] Step 102: taking micron-scale pores or densely distributed parts of pores on the carbonatite sample as the first plunger sample, and performing micron CT scanning on the first plunger sample to obtain a second scanning image;

[0034] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com