Electromagnetic energy-saving concrete vibrator

An energy-saving concrete technology, which is applied in construction, building structure, and building material processing, can solve the problems of high energy consumption, difficulty in realizing circular vibration, and affecting vibration amplitude and output power, etc., and achieves low energy consumption and low cost. Low, weak noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

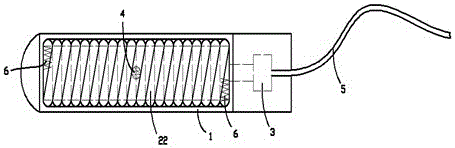

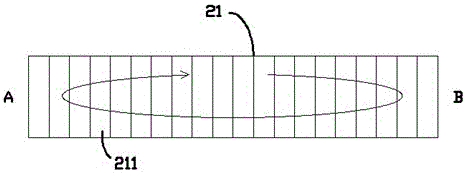

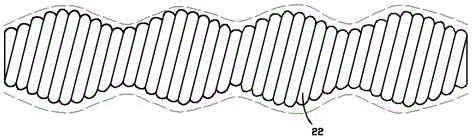

[0015] exist figure 1 , figure 2 In the shown embodiment, the electromagnetic energy-saving concrete vibrator includes a vibrating rod; the vibrating rod includes a shell 1 and an internal structure, and the internal structure includes a section of electromagnetic rod 21 extending along the axis of the vibrating rod; the electromagnetic rod 21 is composed of two or more sections of the same cylindrical electromagnet 211 connected in series, each section of electromagnet 211 is isolated and fixed by a non-magnetic material, thereby greatly weakening the influence of the magnetic force between adjacent electromagnets 211; The electromagnets 211 are respectively coupled to the same control module 3 located in the housing; as figure 2 As shown, assuming that one end of the electromagnetic rod is the A end, and the other end is the B end, the control module 3 connects each of the electromagnets 211 from the A end to the B end of the electromagnetic rod, and then from the B end t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com