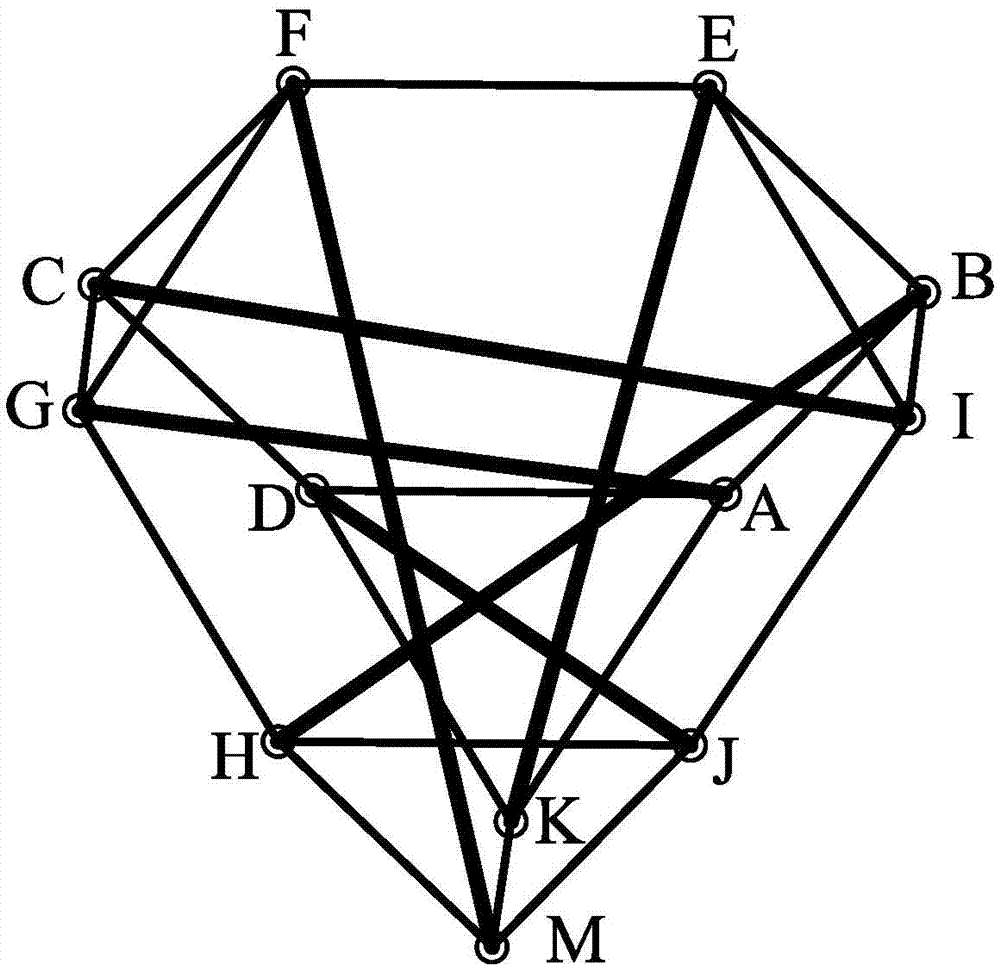

Tensegrity structure similar to truncated tetrahedron

A technique of tensioning the overall structure and tetrahedron, which is applied in special structures, building components, building structures, etc., can solve problems such as single structure types, and achieve multi-functional, large structural bearing capacity, and rich and diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] to combine Figure 1~4 , the tensegrity structure of the truncated tetrahedron in the present invention has a shape obtained by cutting off the four corners of the regular tetrahedron respectively, and the small regular tetrahedron whose edge length is 1 / 3 of the original edge length is obtained. The overall tension structure of the truncated tetrahedron is composed of 12 nodes, 18 cables and 6 compression bars. The 12 nodes are respectively located at the vertices of the truncated tetrahedron and distributed on a spherical surface, namely Circumscribed ball, the radius of the circumscribed ball is 1.1726 times the length of the cable; 18 cables are distributed on the edges of the truncated tetrahedron, and 6 pressure rods are located inside the truncated tetrahedron, distributed as follows: the surface of the truncated tetrahedron There are four equilater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com