Prefabricated assembly type self-restoration frame structure

A frame structure, prefabricated assembly technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of poor self-resetting performance, energy consumption performance, difficult safety, etc., to achieve improved seismic performance, convenient construction, strong self- The effect of reset performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

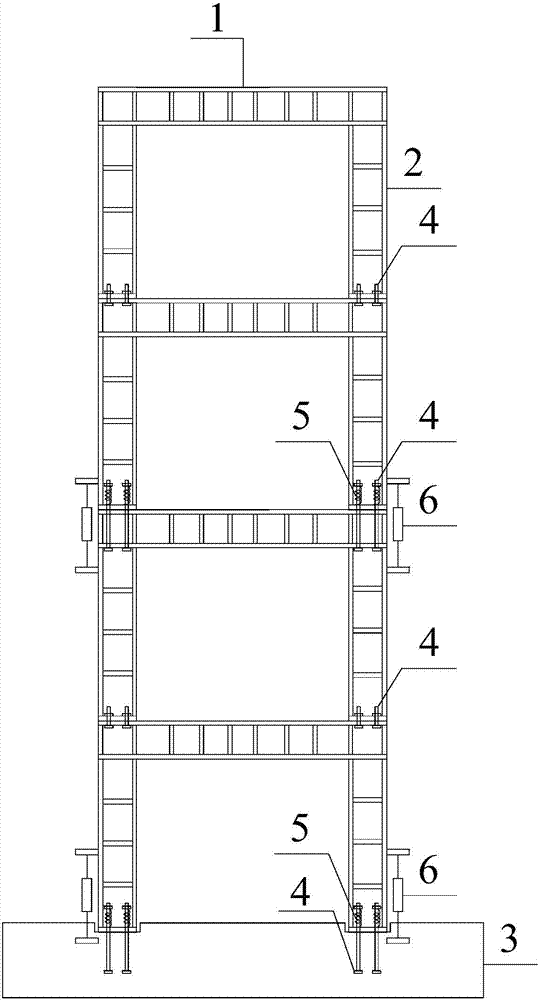

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

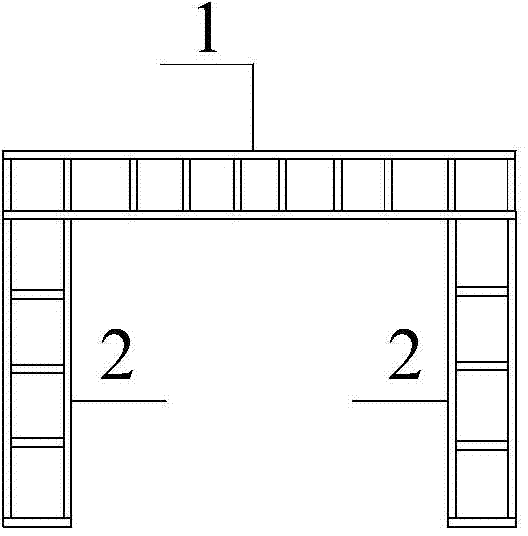

[0019] as attached Figure 1~3 As shown, the present invention is a prefabricated assembled self-resetting frame structure, which is composed of at least 2 prefabricated modules, the height of the prefabricated modules is 1 to 3 stories high, and the described prefabricated modules include beams 1 and columns 2, The prefabricated modules on the ground floor and the foundation 3 are connected by high-strength bolts 4 and springs 5, and a damper 6 is installed between the prefabricated modules on the ground floor and the foundation 3, and at least one layer between the adjacent prefabricated modules is passed through high-strength Bolts 4 and springs 5 are connected, and dampers 6 are installed between adjacent prefabricated modules of this layer, and other adjacent prefabricated modules only need to be connected by high-strength bolts 4 .

[0020] The beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com