Washing machine deceleration clutch anti-seepage device and washing machine thereof

A deceleration clutch and anti-leakage technology, which is applied in the field of washing machines, can solve the problems of sand entering, lip failure, etc., and achieve the effect of improving the overall life, reducing the failure rate, and enriching the design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

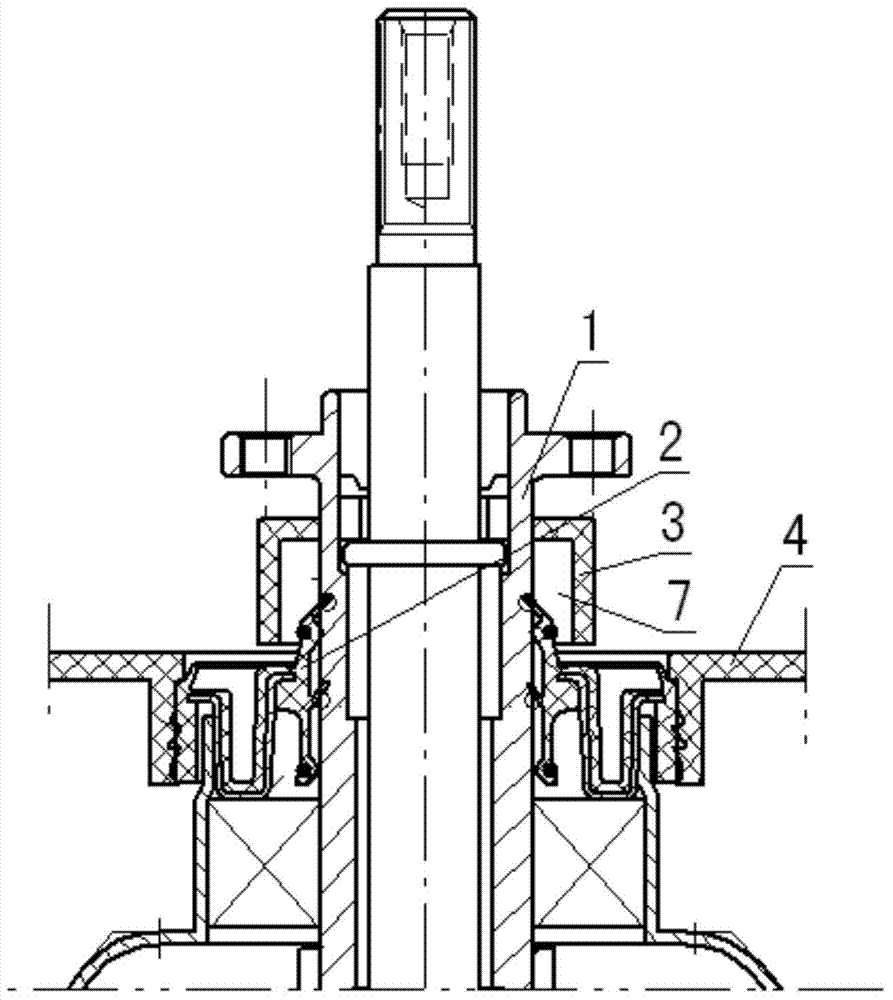

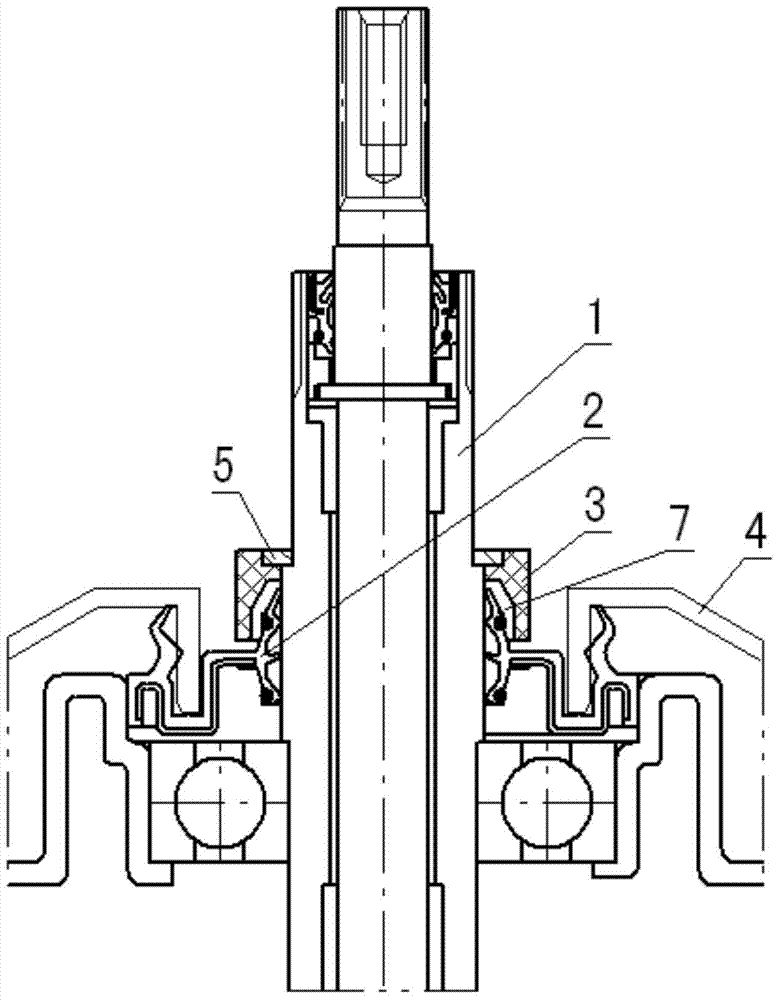

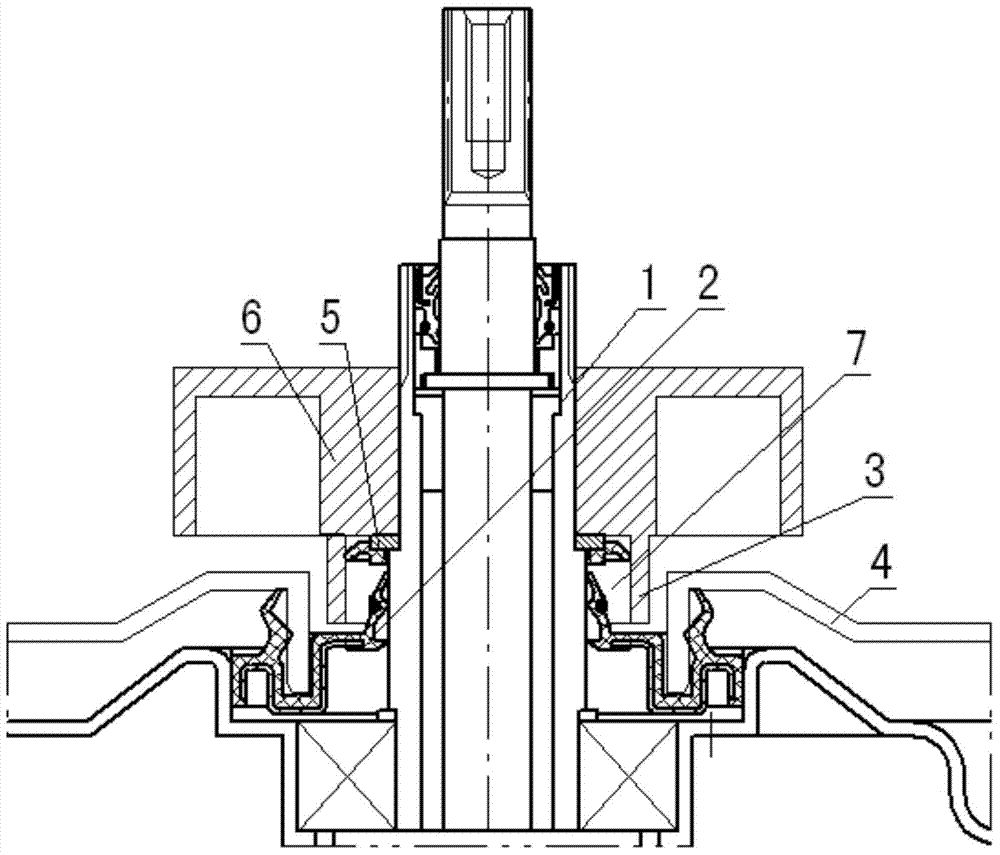

[0021] to combine figure 1 , is a schematic structural diagram of the first embodiment of the present invention in which the deceleration clutch anti-leakage device of the washing machine is arranged on the flange type dehydration shaft, which includes a dehydration shaft 1, a large water seal 2, and the large water seal 2 passes through the soft lip and the dehydration shaft 1 The outer lip of the large water seal 2 is connected to the outer barrel 4, and also includes an anti-leakage component 3, an air chamber 7 with an open end is formed between the anti-leakage component 3 and the large water seal 2; One end of the anti-leakage component 3 is installed on the dehydration shaft 1, and is firmly connected with the dehydration shaft 1 without any gap; the anti-leakage component 3 is made of rubber.

[0022] In the washing machine manufactured by applying the above-mentioned deceleration clutch anti-leakage device of the washing machine, the flange screw hole of the dehydrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com