Negative pressure guide capturing type ring spinning method

一种环锭纺纱、负压的技术,应用在纺纱机、连续卷绕的纺纱机、纺织品和造纸等方向,能够解决纺纱作用效果差、成纱品质得不到改善、附着抱合作用力弱等问题,达到增加纤维利用率、节约生产成本、提高成纱强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In the cotton fiber siro spinning process, the yarn quality of ring spinning is improved.

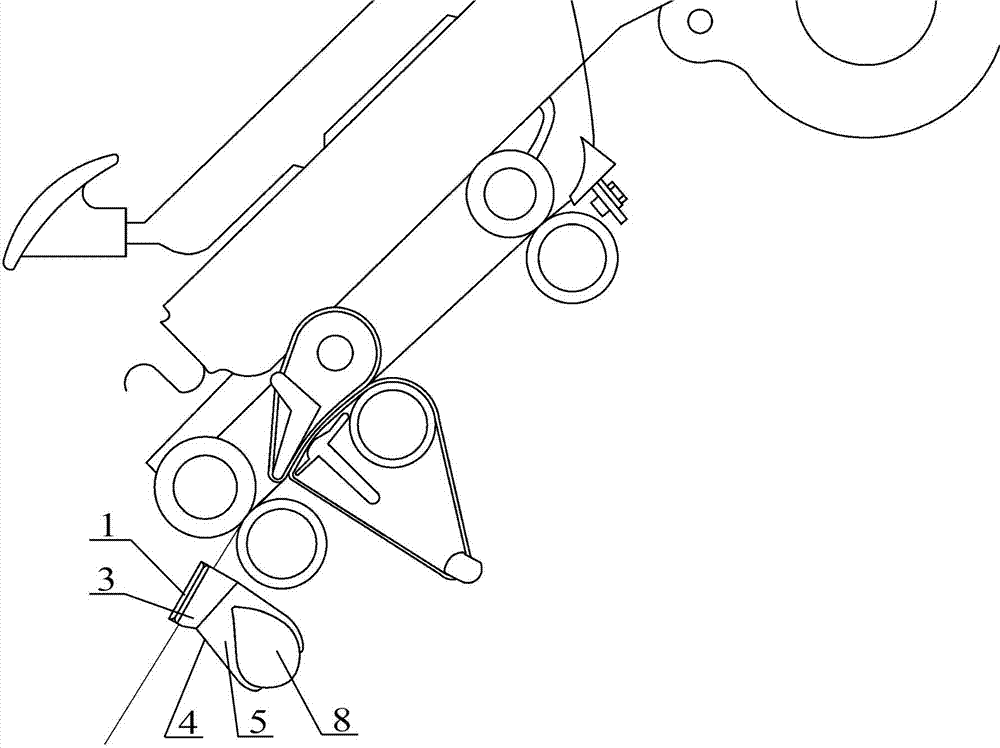

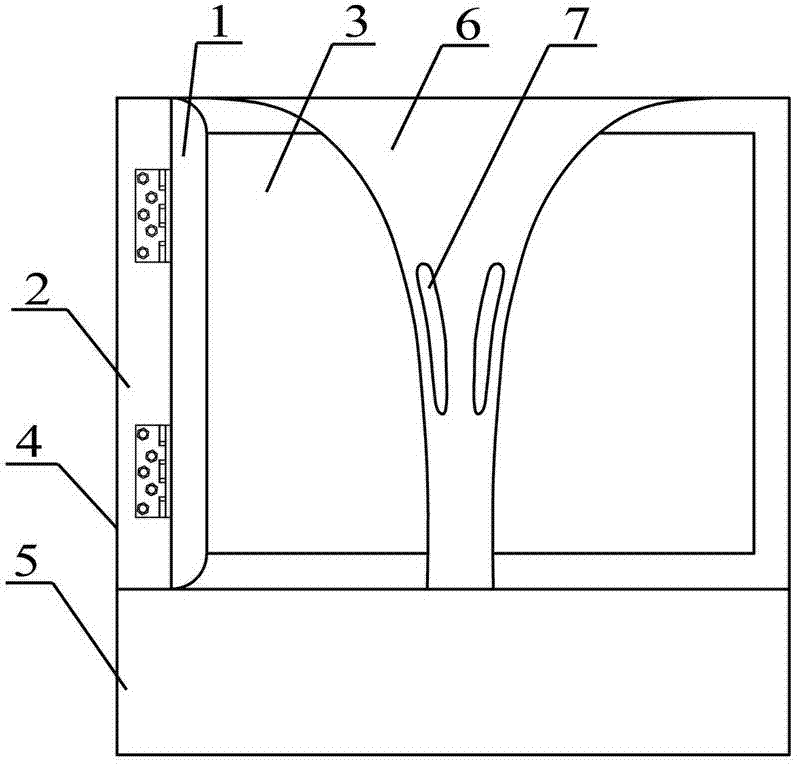

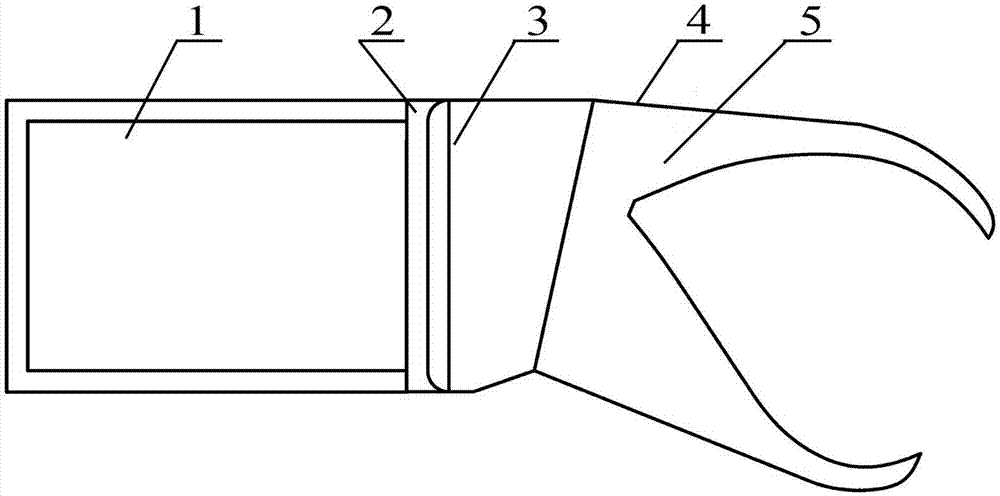

[0019] On the cotton-type ring spinning frame, the negative pressure guiding and catching device is fixedly installed on the pear-shaped suction bag pipe 8 through the base 5, and connects the suction bag pipe 8 and the suction channel in the catch holder 3, Negative pressure airflow is generated in the holding groove 6 through the air suction port 7, and the two cotton rovings enter a drafting system of the ring spinning frame through a double bell mouth feeder with a distance of 4 mm. The front roller composed of the front rubber roller and the front roller is output by the nip of the front roller, and the output two whiskers are merged and twisted into a sliver, and the twisted composite sliver immediately enters the holding groove 6 of the catcher 3, and the air suction port The ratio of the width of the holding groove 6 at 7 to the outlet width of the holding groove 6 is 1.5...

Embodiment 2

[0021] Improve the yarn quality of ring spinning in wool siro core-spun compound spinning process.

[0022] On the wool-type ring spinning frame, cancel the wool-type single-pipe suction pipe system per spindle, and refit it into a pear-shaped suction pipe 8 for cotton spinning. The negative pressure guiding and catching device is fixedly installed on the suction pipe 8 through the base 5 on, and the suction bagpipe pipe 8 is connected with the suction channel in the catch holder 3, and the two wool rovings enter a drafting system of the wool-type ring spinning frame through a double bell mouth feeder with a distance of 6 mm. After being drafted by the drafting system, it is output from the front roller nip composed of front rubber roller and front roller, and the polyester filament unwound from the filament package is output from the rear of the front rubber roller through the front roller nip through the yarn guide device. The filament is located in the middle of the left an...

Embodiment 3

[0023] Embodiment 3: In the process of ramie long fiber ring spinning, improving the forming quality of ramie single yarn

[0024] On the ring spinning frame of long linen spinning, cancel the single-tube suction pipe system of each spindle of long linen spinning, and refit it into a pear-shaped suction pipe 8 for cotton spinning, and the negative pressure guiding and catching device is fixedly installed on the suction pipe 8 through the base 5 and connect the suction bagpipe pipe 8 with the suction channel in the catching gripper 3, a ramie roving enters a drafting system of the wool-type ring spinning frame through the feeding horn, and after being drafted by the drafting system , output from the front roller nip composed of front rubber roller and front roller, the ramie strands output from the front roller nip are twisted into composite yarn under the action of twisting, and the twisted composite yarn immediately enters the catcher In the holding groove 6 of 3, the ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com