Three-dimensional braided composite material propeller blade for airplane and manufacturing method of propeller blade

A composite material and three-dimensional weaving technology, which is applied in the direction of propellers, aircraft parts, transportation and packaging, etc., can solve the problems of weak interlayer strength of blade composite materials, achieve high production efficiency, increase strength and stiffness, and high molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

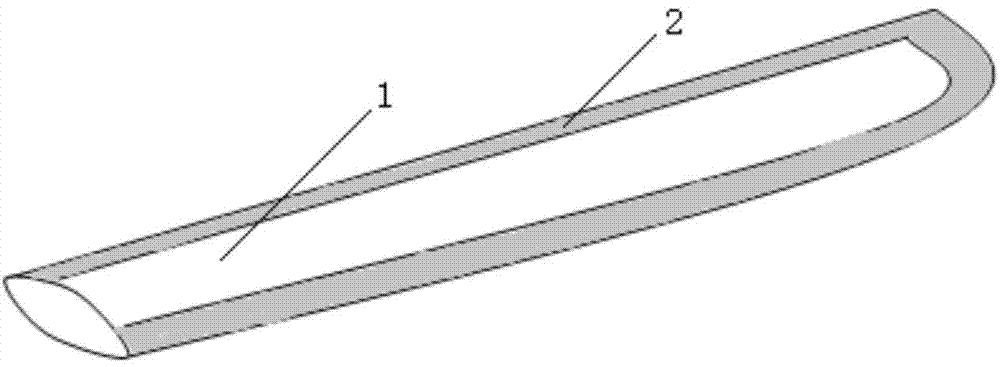

[0033] figure 1 It is a schematic diagram of the mold structure of the propeller blade of the present invention, and the mold includes a blade main body 1 and a blade edge reinforcement structure 2 arranged on the edge of the blade main body. The three-dimensional braided structure of the propeller blade of the present invention is based on figure 1 The mold structure in the weaving molding.

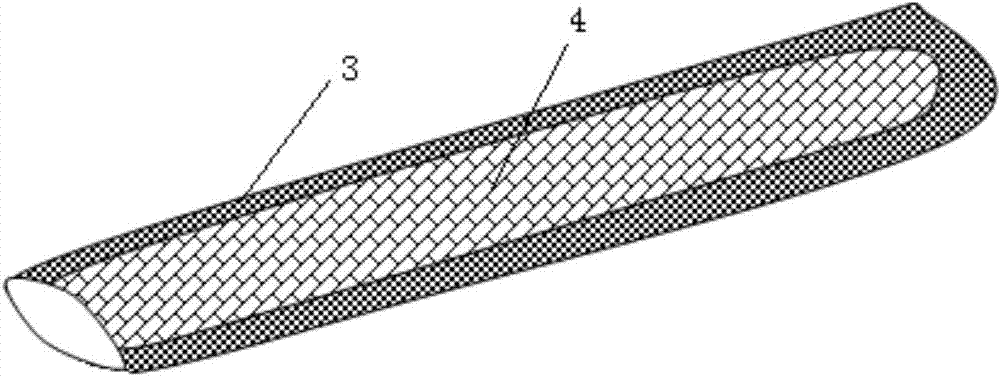

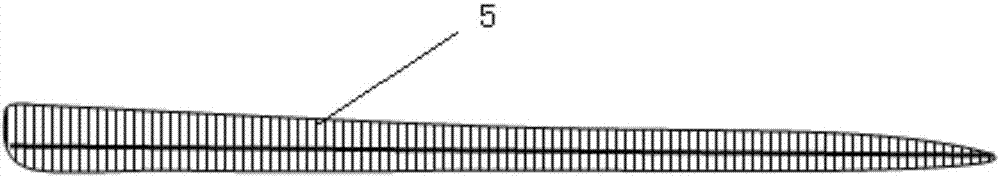

[0034] Such as figure 2 and image 3 As shown, a propeller blade of a three-dimensional braided composite material for aircraft includes an internal three-dimensional braided structure and a resin layer impregnated and cured on the three-dimensional braided structure, and the three-dimensional braided structure includes a main body of the three-dimensional braided structure Part 4, the edge reinforcement structure 3 of the three-dimensional braided structure and the secondary stitching structure 5 along the thickness direction of the blade.

[0035] based on figure 1 The mold in th...

Embodiment 2

[0038] based on figure 1 Three-dimensional weaving is carried out on the mandrel, and the weaving scheme of the main body inside the blade is as follows: the main part 4 of the three-dimensional weaving structure is processed by three-dimensional five-way weaving, the yarn is T300 carbon fiber, and the edge reinforcement structure 3 of the three-dimensional weaving structure is three-dimensional For four-way braiding, one or a combination of T300 and T700 is used for the weaving yarn on the edge of the blade. The overall three-dimensional braided propeller blade has a length of 4m and a width of 1m. The woven prefabricated body continues to be sutured for the second time in the thickness direction, and T300 carbon fiber is selected as the reinforcing yarn, and the proportion of suture fiber accounts for 15% of the overall prefabricated body fiber proportion. The suture structure schematic diagram is as follows image 3 shown.

[0039] The prefabricated carbon fiber blade aft...

Embodiment 3

[0041] based on figure 1Three-dimensional weaving is carried out on the mandrel, and the weaving scheme of the main body inside the blade is as follows: the main part 4 of the three-dimensional weaving structure adopts three-dimensional four-way weaving, the yarn uses T700 carbon fiber, and the edge reinforcement structure 3 of the three-dimensional weaving structure adopts three-dimensional Five-way weaving treatment, one or a combination of T300 and T700 is selected as the weaving yarn for the edge of the blade. The overall three-dimensional braided propeller blade has a length of 3m and a width of 0.6m. The woven prefabricated body will continue to be sutured for the second time in the thickness direction, and T700 carbon fiber is selected as the reinforcing yarn. The proportion of suture fiber accounts for 25% of the overall prefabricated body fiber proportion. The suture structure schematic diagram is as follows image 3 shown.

[0042] The carbon fiber blade preform af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com