Double-face multicolor hard pressing soft offset press

A technology of offset printing and double-sided printing, applied in printing presses, rotary printing presses, offset rotary printing presses, etc., can solve the problems of high number of paper handovers, poor versatility, and easy smearing of printed products, and achieves compact structure. , improve the versatility and interchangeability, the effect of high quality printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

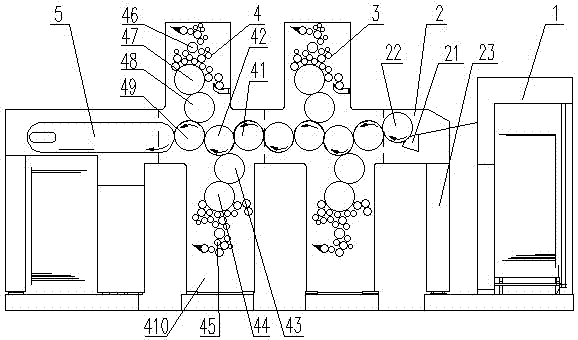

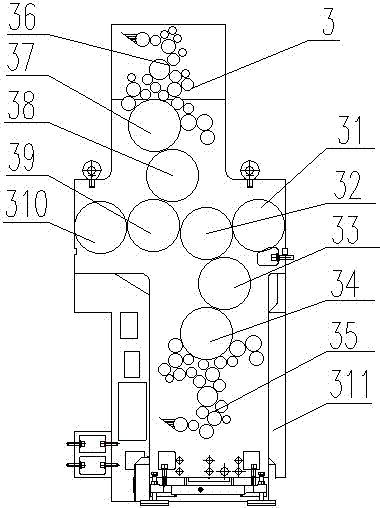

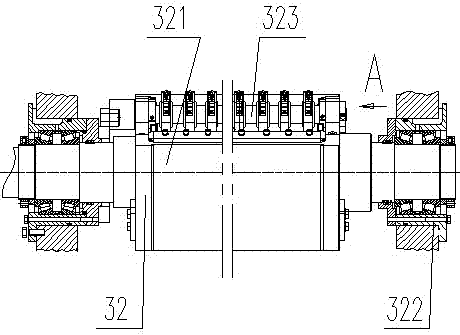

[0028] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Image 6 , attached Figure 7 , attached Figure 8 , attached Figure 9 , attached Figure 10, a double-sided multi-color hard-press soft offset printing machine of the present invention, it is made up of paper feeding part 1, front transmission part 2, at least one set of double-sided printing unit 3, paper delivery end printing unit 4, paper delivery part 5, this The embodiment adopts a group of double-sided printing units 3 to form a double-sided two-color hard-press soft offset printing machine; the paper feeding part 1 is connected with the front passing part 2, and the paper transfer cylinder and the impression cylinder of the double-sided printing unit 3 , rubber cylinder, and printing plate cylinder are in the form of a structure with equal diameters, and the cylinder arrangement adopts the printing method of impression cylinder and im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com