Method for supporting curved glass and supporting platform thereof

A technology of curved glass and support table, applied in the direction of measuring device, instrument, measuring force, etc., to achieve the effect of improving detection accuracy, stable support, and fast and accurate adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

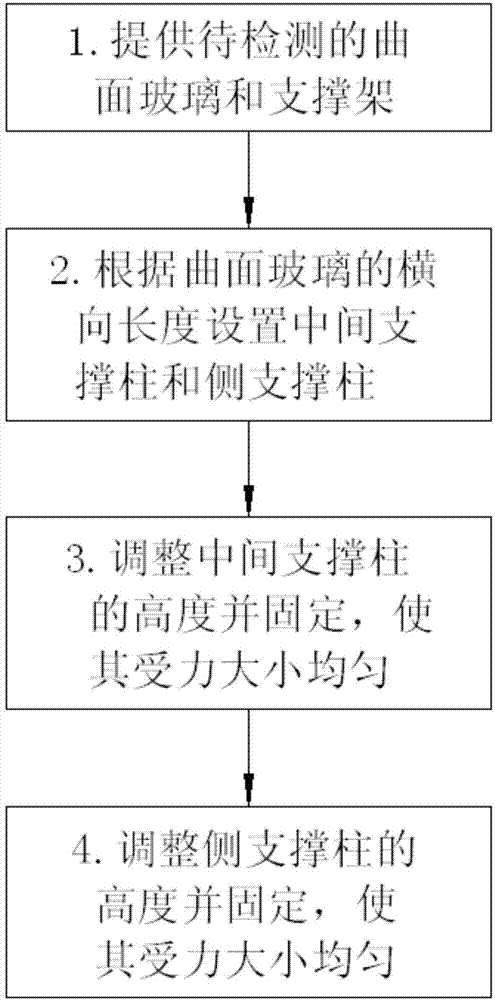

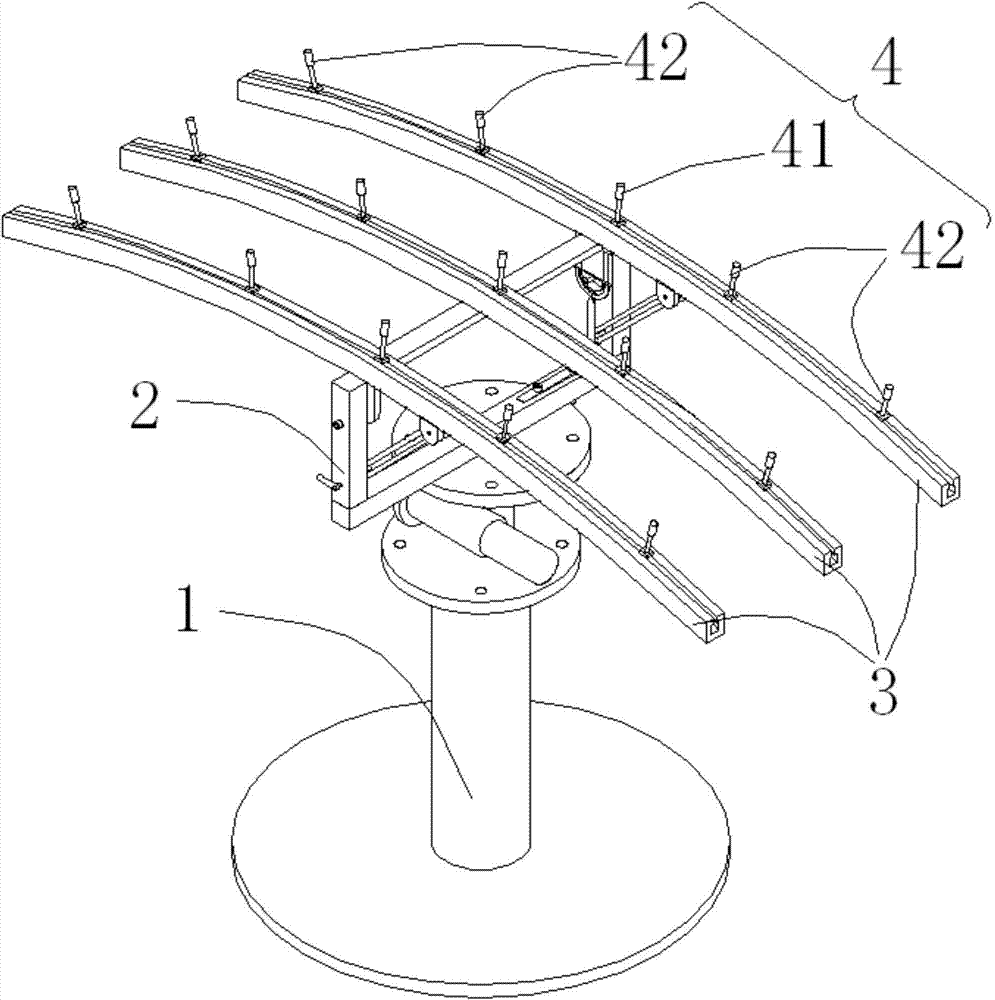

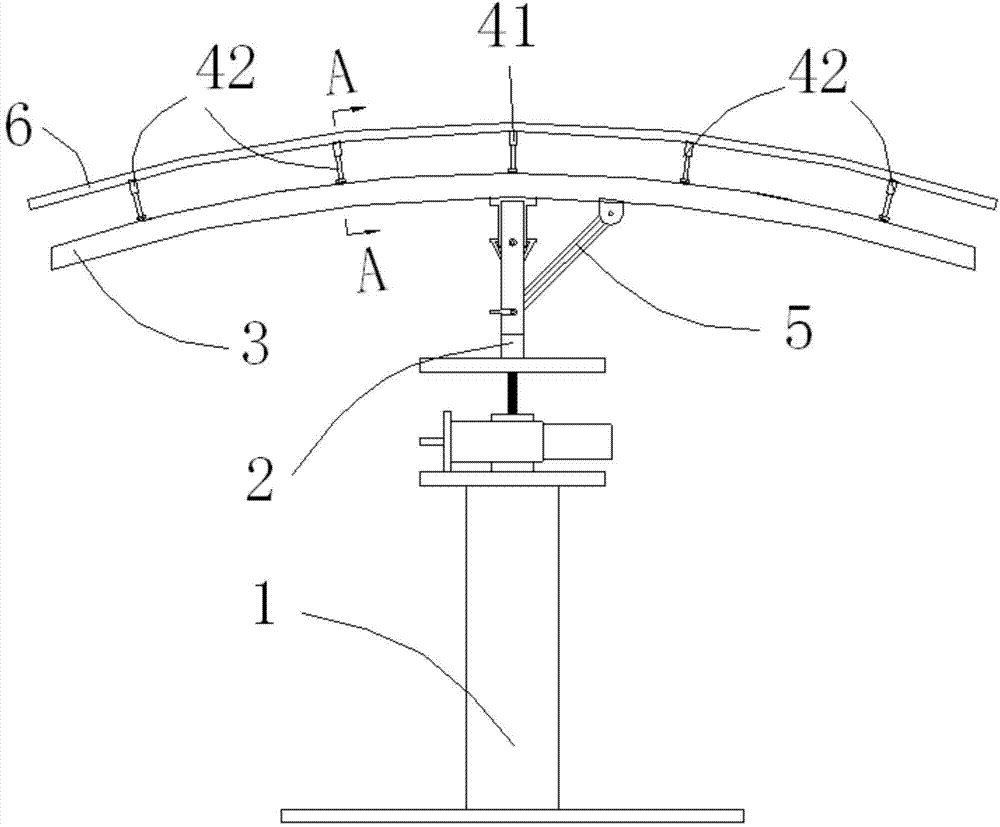

[0048] Step 1: Provide the curved glass 6 to be tested, whose transverse length L=1200mm, longitudinal length 640mm, and weight 8.5Kg. The length of the arc guide rail 3 is 1100mm, and the distance between two adjacent arc guide rails 3 is 300mm, and there are 3 arc guide rails (a, b, c) in total.

[0049] Step 2: According to the horizontal length L, set one intermediate support column and four side support columns on the curved guide rail 3, and the distance L between the two side support columns is symmetrical to each other 1 =360mm, L 2 =960mm.

[0050] Step 3: Place the curved glass 6 on the curved guide rail 3, so that the lateral direction of the curved glass 6 is parallel to the guide of the curved guide rail 3, and the center line of symmetry of the curved glass 6 is located at the middle support column 41 directly above; then, raise the middle support column 41 so that the symmetrical center line is supported on the middle support column 41; then, adjust the height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com