Method capable of automatically adjusting rotation radius and measuring inner diameter and outer diameter of pipe end of steel pipe

A technology of automatic adjustment of the rotation radius, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of high processing accuracy, inability to complete measurement, high cost, etc., achieve good compatibility, make up for the limited measurement range, reduce The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

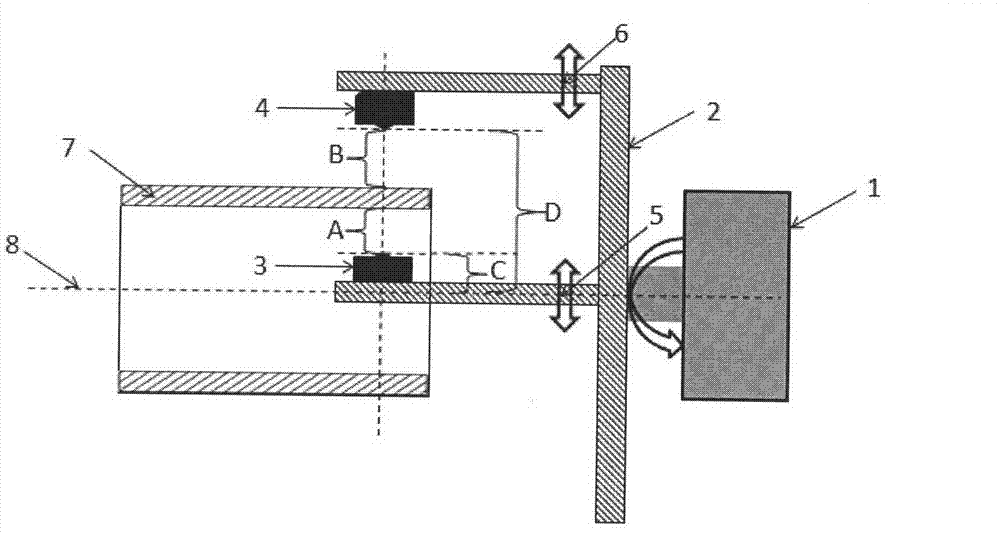

[0018] The present invention is directed to a pipe end inner and outer diameter measuring device based on a rotating platform driving a laser ranging probe to rotate around the pipe end. The structure of this device is as follows: figure 1 shown.

[0019] exist figure 1 Among them, 1 is the turntable, 2 is the turntable table, 3 and 4 are the inner diameter distance measuring probe and the outer diameter distance measuring head respectively, 5 and 6 are the inner diameter probe fixing arm and the outer diameter probe used to fix the two probes respectively. The fixed arm, 7 is the steel pipe to be tested, and 8 is the rotation axis of the rotary table. The two laser ranging probes 3 and 4 are placed perpendicular to the pipe wall, and the distances between the probes and the inner and outer walls of the steel pipe are measured as A and B, respectively. The distances of the laser ranging probes (3 and 4) from the central axis (8) of the rotation of the turntable are C and D r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com