Anti-freezing rapid water taking valve

A water intake valve, fast technology, applied in the direction of lifting valve, valve details, valve device, etc., can solve problems such as easy water leakage and difficult connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

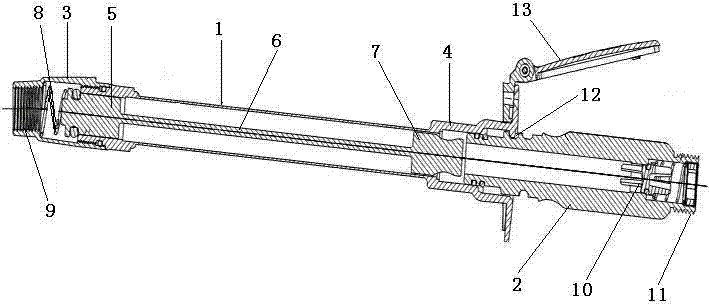

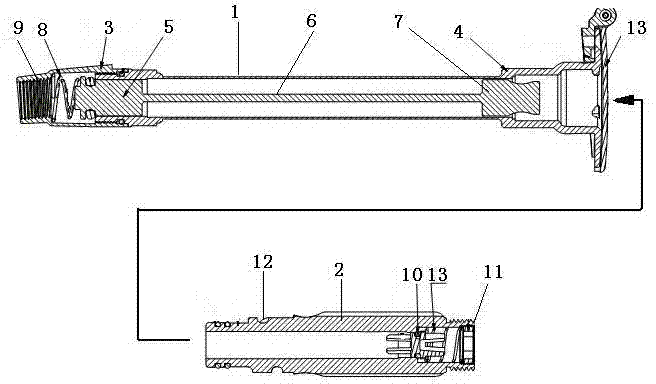

[0013] Embodiment 1: The length of the valve pipe 1 is set according to the thickness parameter requirements of the cold-proof and heat-insulating body. Connect the water supply connection end 9 of the upper valve body 3 to the running water pipe, and the lower valve body 4 presses on the inclined gasket 14 and inclines downward at 5° to fix it.

Embodiment 2

[0014] Embodiment 2: Connect the water diversion pipe to the water outlet connection end 11 of the valve handle body 2 as required, lift the windshield and dustproof cover 13, and snap the comma-shaped card slot 12 of the valve handle body 2 to the water intake valve of the lower valve body 4 The handle is connected to the card, the valve handle body 2 rotates along the spiral groove to produce a linear motion, and the upper end squeezes the lower piston 7 to move upward, and the lower piston pushes the upper piston 5 to move upward through the connecting rod 6, so that the lower piston 7 and the upper piston 5 move simultaneously. When the water flow channel is formed between the lower valve body 4 and the inner wall of the upper valve body 3, the return spring 8 is compressed to accumulate force for the return of the piston. Tap water flows through the inner cavity of the upper valve body 3, the valve pipe 1, the lower valve body 4, and the valve handle body 2, and is transpo...

Embodiment 3

[0015] Embodiment 3: When it is necessary to stop taking water, reverse the valve handle body 2 and take it out. At this time, because of the double protection of the double sealing ring, when the valve handle body 2 is moving outward, the return spring 8 is stretched to push the piston back to close the inner cavity of the upper valve body 5, and the sealing ring of the valve handle body 2 has not yet completely When leaving the position, the pressure in the valve pipe 1 has been reduced, preventing the spraying of water; there is a time difference between the upper piston 5 closing the inner cavity channel of the upper valve body 3 and pressing the sealing ring. During this time difference, there is a gap between the lower piston 7 and the inner cavity of the lower valve body 4, and the water remaining in the valve tube 1 is discharged due to inclination. When the sealing ring of the upper piston 5 is completely compressed, the remaining water is emptied, and the lower pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com