A Maintainable Centrifugal Axial Fan

A maintainability and centrifugal shaft technology, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids, can solve problems such as fan failures, difficulties, and high costs, and save maintenance Cost and maintenance efficiency, overcoming misjudgment defects, improving scientific and accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

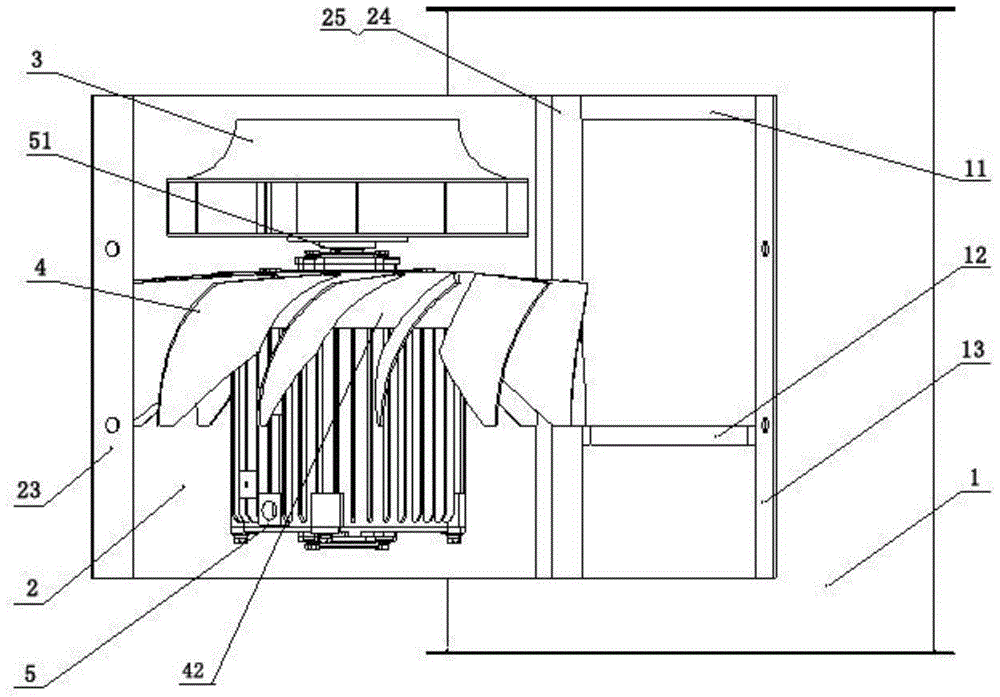

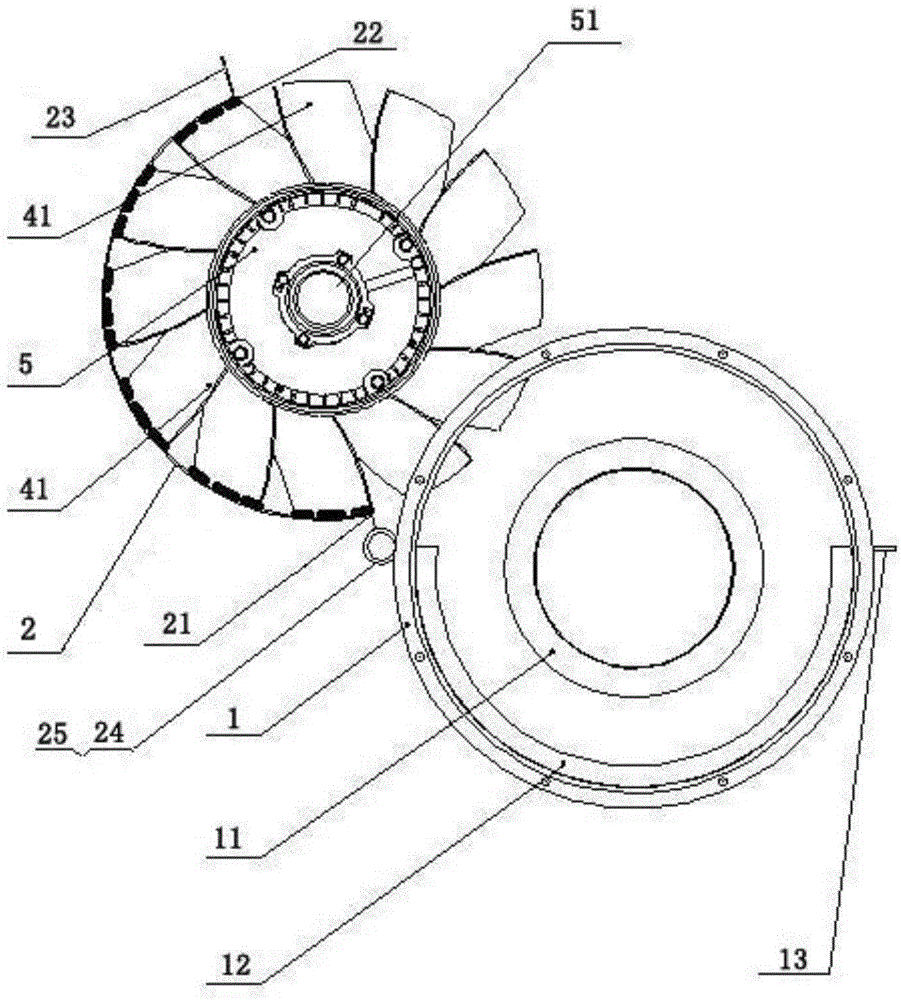

[0031] A maintainable centrifugal axial flow fan, see figure 1 and figure 2 , specifically including an air cylinder with a cavity at both ends, an arc door, a turning mechanism, a centrifugal impeller, a rear guide vane and a motor. The blower can be arranged horizontally or vertically, and in this embodiment, the vertical arrangement is used for description.

[0032] The upper end of the air cylinder 1 is provided with an air inlet channel 11 corresponding to the centrifugal impeller 3 , preferably: the cavity diameter of the air inlet channel 11 is the same as that of the centrifugal impeller 3 .

[0033] In the vertical direction, the side wall of the air cylinder 1 is provided with an opening, the opening is preferably located in the middle of the air cylinder 1, and the arc door 2 is arranged at the opening of the side wall of the air cylinder 1 and is connected with The size of the curved door 2 is matched, and one side of the curved door 2 can be turned over on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com