Parallel ruler for roller spacing adjustment

A technology of spacing and rollers, which is applied in the field of spacing adjustment, can solve the problems of affecting the equipment's weaving rate, spending a lot of working time, and long adjustment time, so as to reduce the time for adjusting the rollers when the equipment is shut down, facilitate adjustment and pick-and-place, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

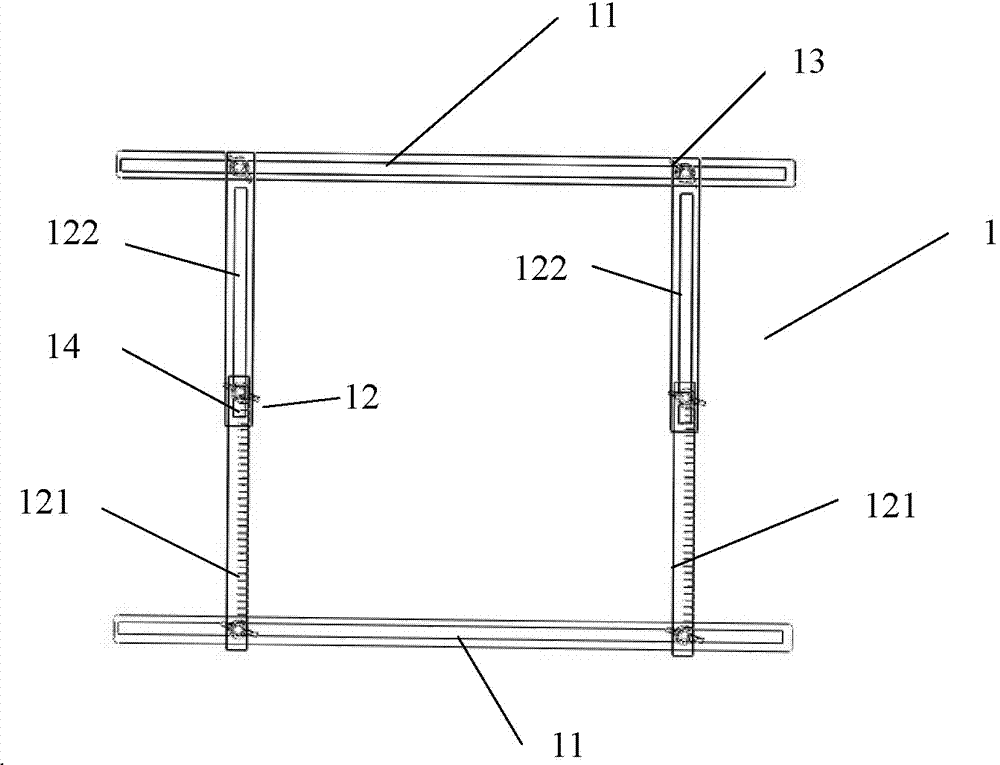

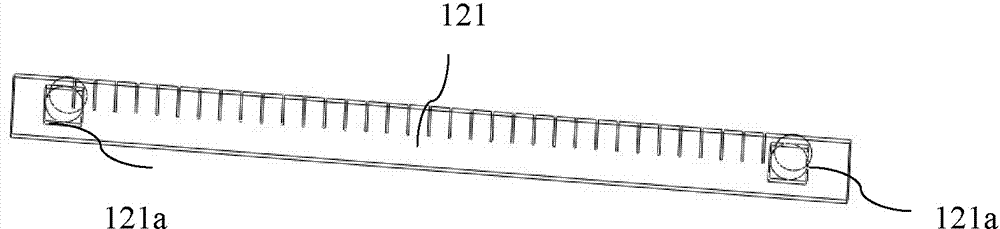

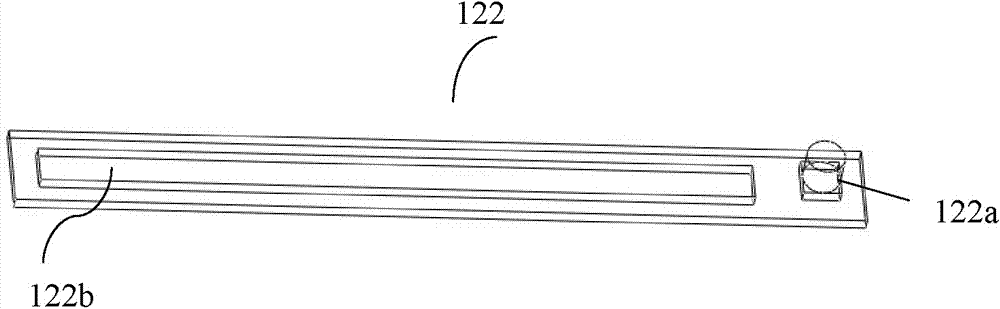

[0018] like Figure 1-Figure 5 As shown, the parallel ruler 1 for adjusting the distance between rollers of the present invention includes at least two first straight plates 11 parallel to each other, and at least two mutually parallel first straight plates 11 are vertically connected by first connecting parts 13 between the two first straight plates 11. Parallel adjustment ruler 12. In this embodiment, two first straight plates 11 and two adjustment rulers 12 are taken as examples for illustration. The connection structures of multiple first straight plates 11 or adjustment rulers 12 are the same, and will not be repeated here. The first connecting part 13 includes the first chute 11a arranged on the first straight plate 11 and the protrusions 121a or 122a arranged at both ends of the adjustment ruler 12 (the protrusions 121a, 122a are best set to the same size) . The protrusions 121a, 122a can just fit into the first sliding groove 11a and can slide along the sliding groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com