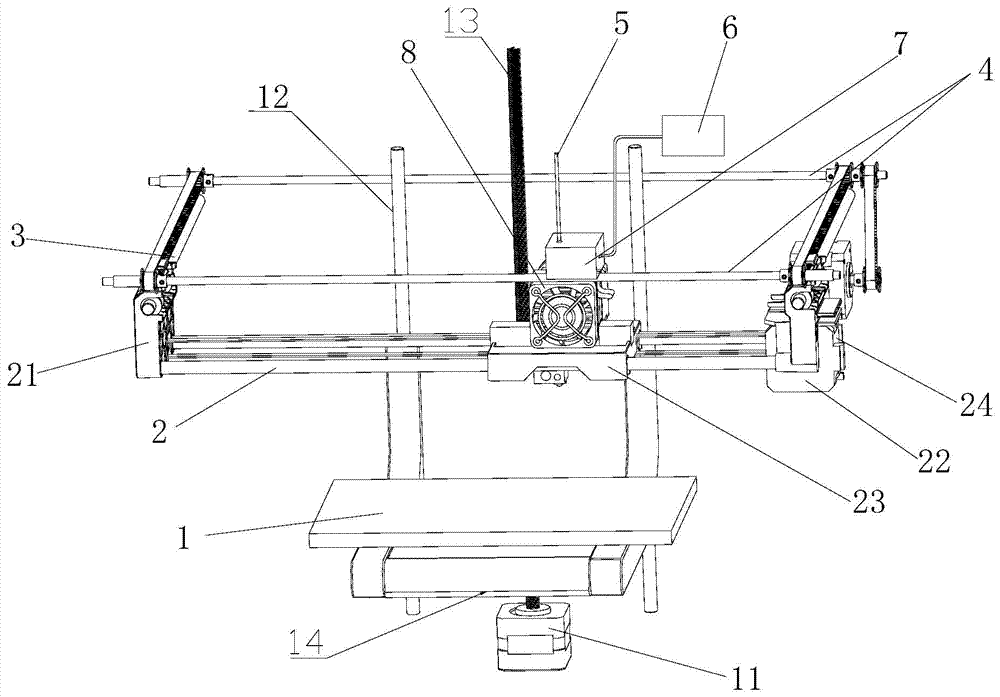

Penetrative full color three-dimensional printing device

A 3D printing, full-color technology, applied in the field of 3D printing, can solve problems such as high cost and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

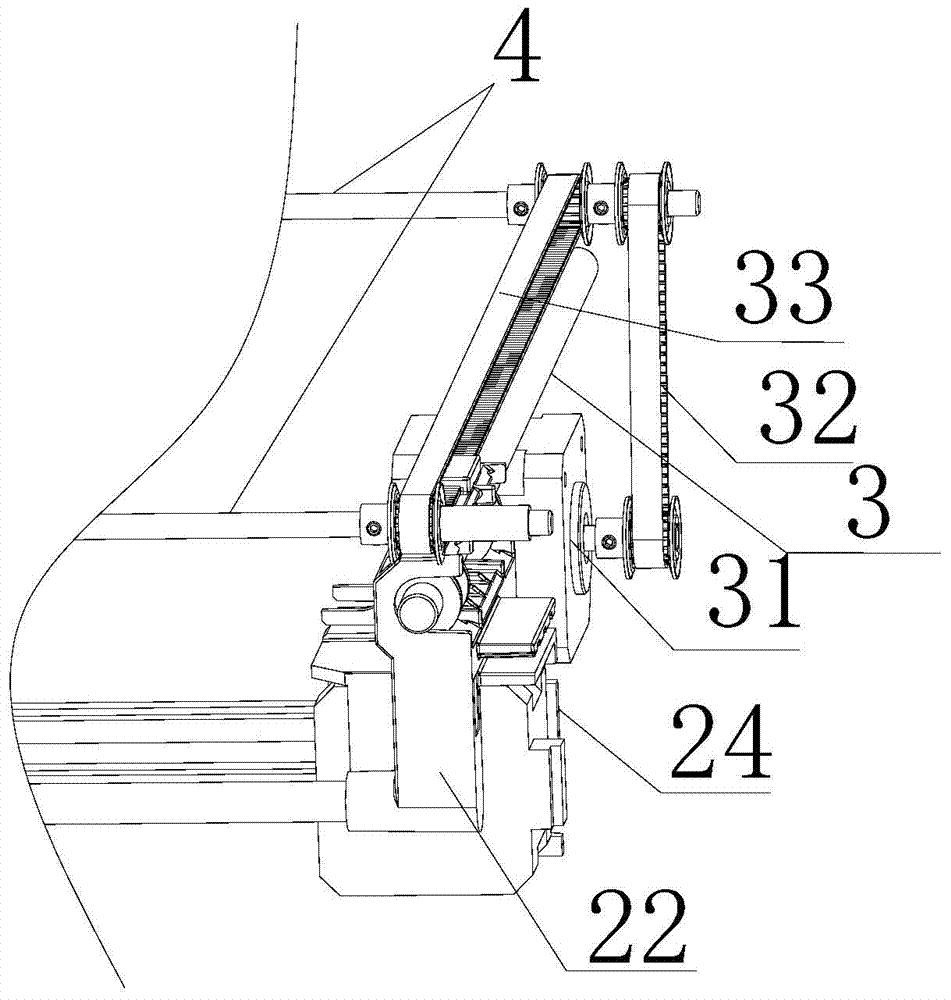

[0054] As another preferred embodiment, the lateral guide shaft 2 in the left-right direction passes through the base 22 (see image 3 ) Is sleeved on the longitudinal guide shaft 3 in the front-rear direction.

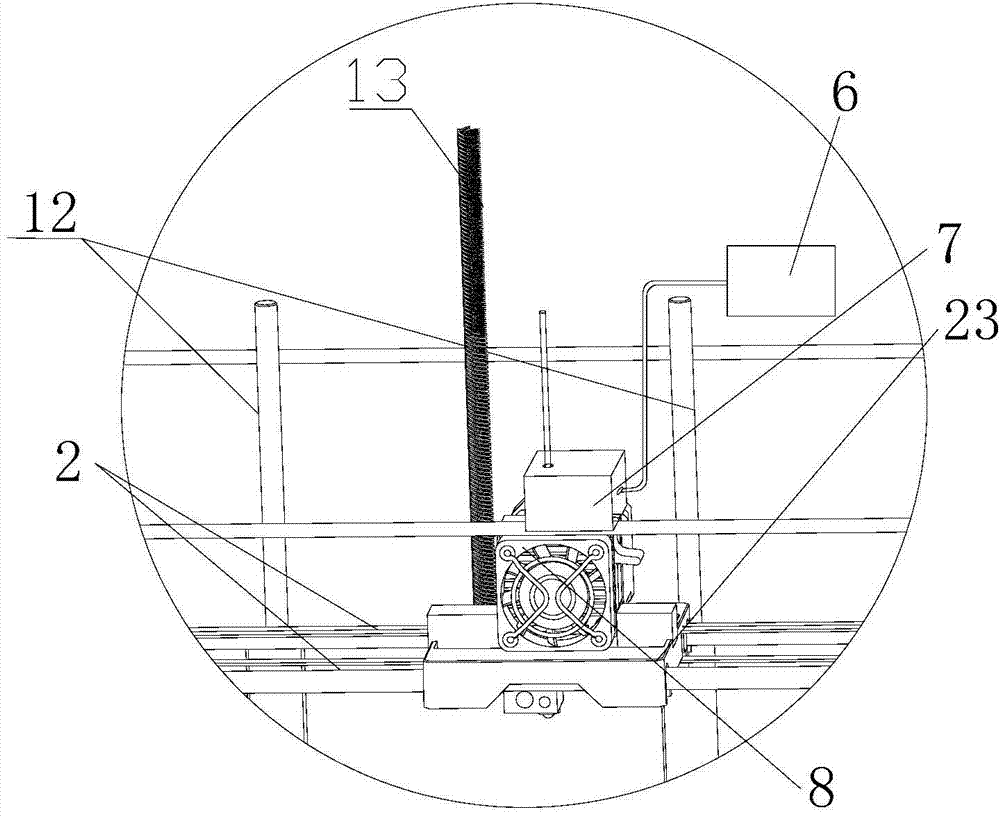

[0055] As another preferred embodiment, the fixed optical axis 4 near the rear side is the driving axis, which is driven by the first stepping motor 31, the fixed optical axis 4 near the front side is the driven axis, and the two fixed optical axes 4 pass through The first synchronous belt 33 rotates synchronously, the first synchronous belt 33 is arranged along the direction of the longitudinal guide shaft 3, and the base 22 is fixedly connected to the first synchronous belt 33. In addition, a second stepping motor 24 is provided on the base 22, and the second stepping motor 24 drives the sliding seat 23 to move along the lateral guide shaft through a second timing belt. The first stepping motor 31 is arranged below the fixed optical axis close to the rear side, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com