An automatic stud welding system for road and bridge expansion joint long sections and large-size round steel

A welding system and long profile technology, which is applied in the field of road and bridge expansion joint long profile and large-size round steel automatic stud welding system, can solve the problems of inconvenient clamping of workpieces, uneven weld seam, low production efficiency, etc., and achieve welding positioning The effect of high accuracy, low labor intensity and uniform welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

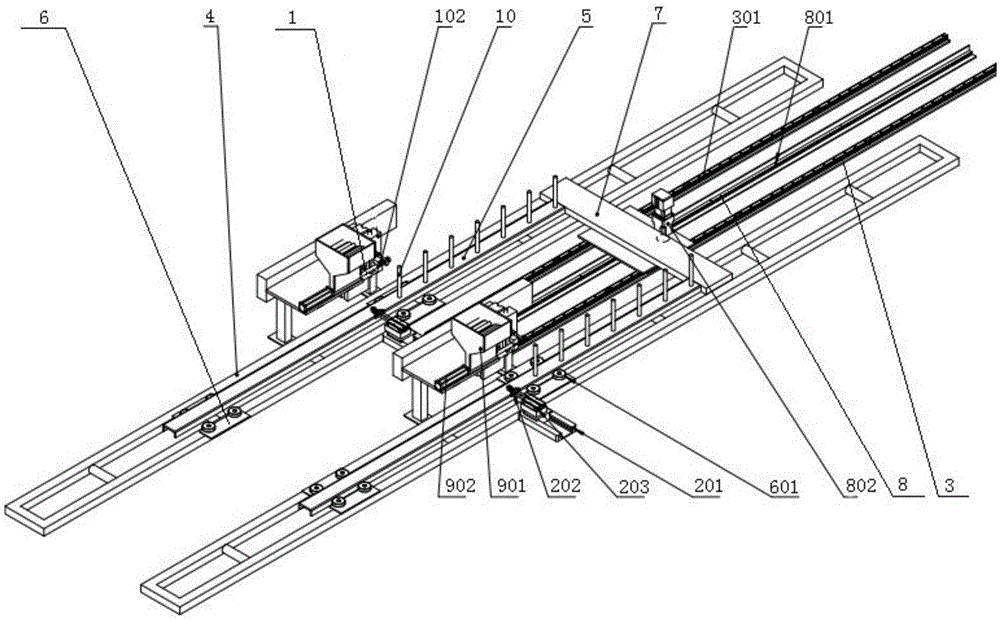

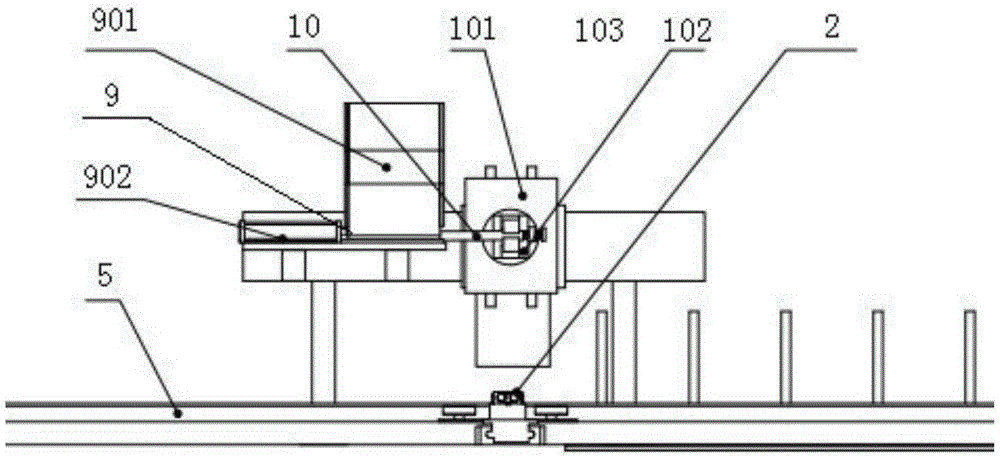

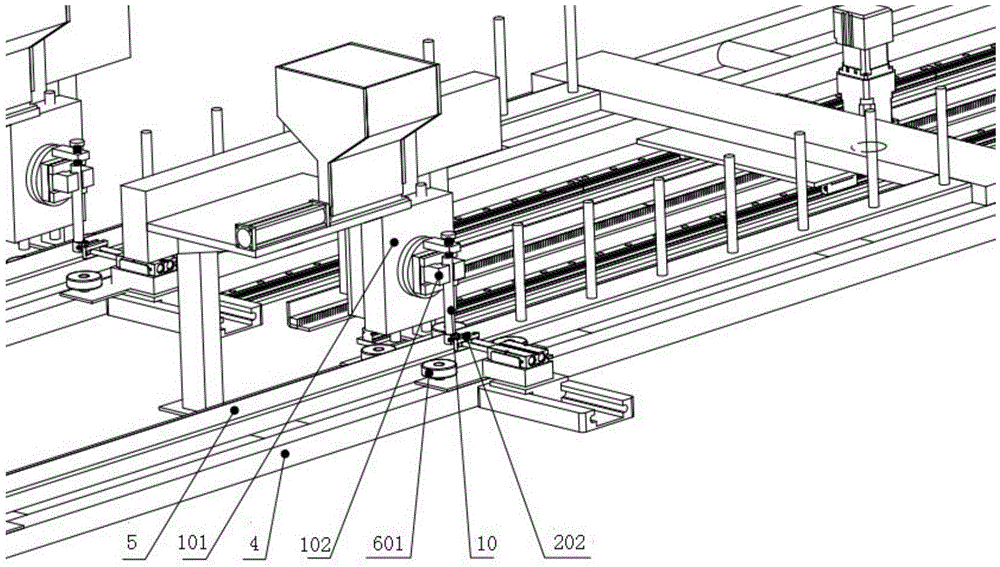

[0030] Such as Figure 1 to Figure 5 As shown, the present invention is an automatic stud welding system for road and bridge expansion joint long profiles and large-size round steel, including a welding manipulator mechanism 1, a split ceramic ring mechanism 2, a guide rail mechanism 3 and a ground rail roller frame 4; the ground rail The long profile 5 to be welded is placed on the roller frame 4, and the long profile 5 is accurately positioned by several profile positioning devices 6 evenly arranged on the ground rail roller frame 4; the guide rail mechanism 3 is arranged on the ground rail roller frame 4, the rail mechanism 3 includes two linear guide rails 301 arranged in parallel; the two linear guide rails 301 are provided with a carriage 7, and the carriage 7 is realized in a straight line by means of the carriage driving device 8 arranged thereon. reciprocating movement on the guide rail 301;

[0031] The welding manipulator mechanism 1 is arranged on one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com