Two-dimensional hollow palladium nanocrystal and preparation method thereof

A palladium nano and hollow technology is applied in the field of preparation of noble metal nano materials, which can solve the problems of high requirements for experimental environment and operation process, and achieve the effects of enhanced catalytic performance, low toxicity and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

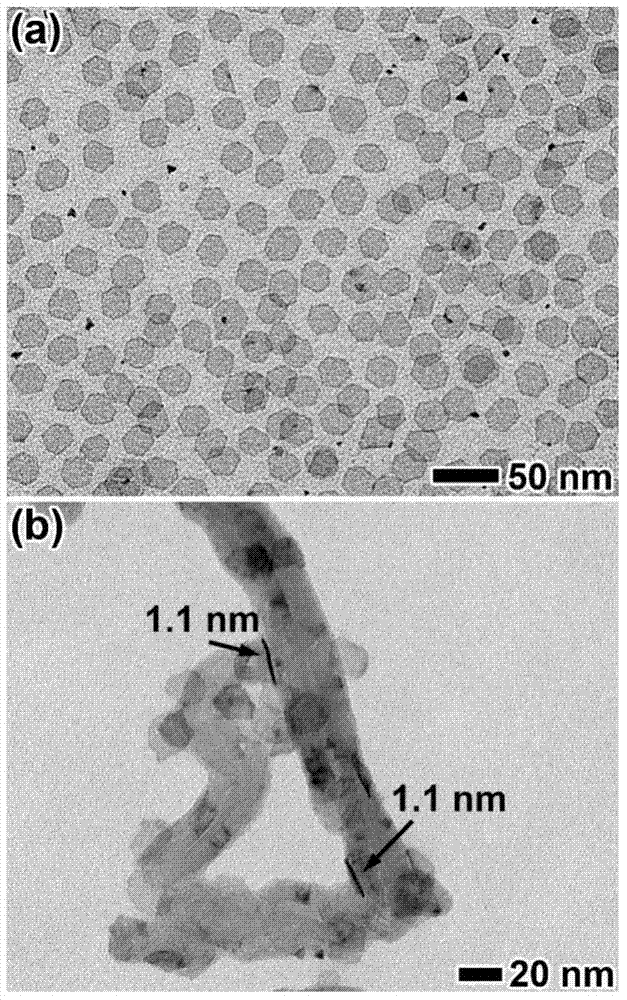

[0043] Step 1. Dissolve 16 mg of palladium acetylacetonate, 60 mg of cetyltrimethylammonium bromide, 100 mg of tungsten carbonyl, 90 mg of citric acid and 30 mg of polyvinylpyrrolidone in 10 mL of N, N dimethylformamide, and stir for 1 h to make each The substance was fully dissolved, and the reaction solution was transferred to a 25mL round bottom flask, and reacted at 80°C for 1h. After the reaction is completed, the reaction solution is centrifuged to obtain hexagonal palladium nanosheets. The morphology of palladium nanosheets is as figure 1 As shown, the hexagonal palladium nanosheets have a thickness of 1 nm and an average side length of 15.7 nm.

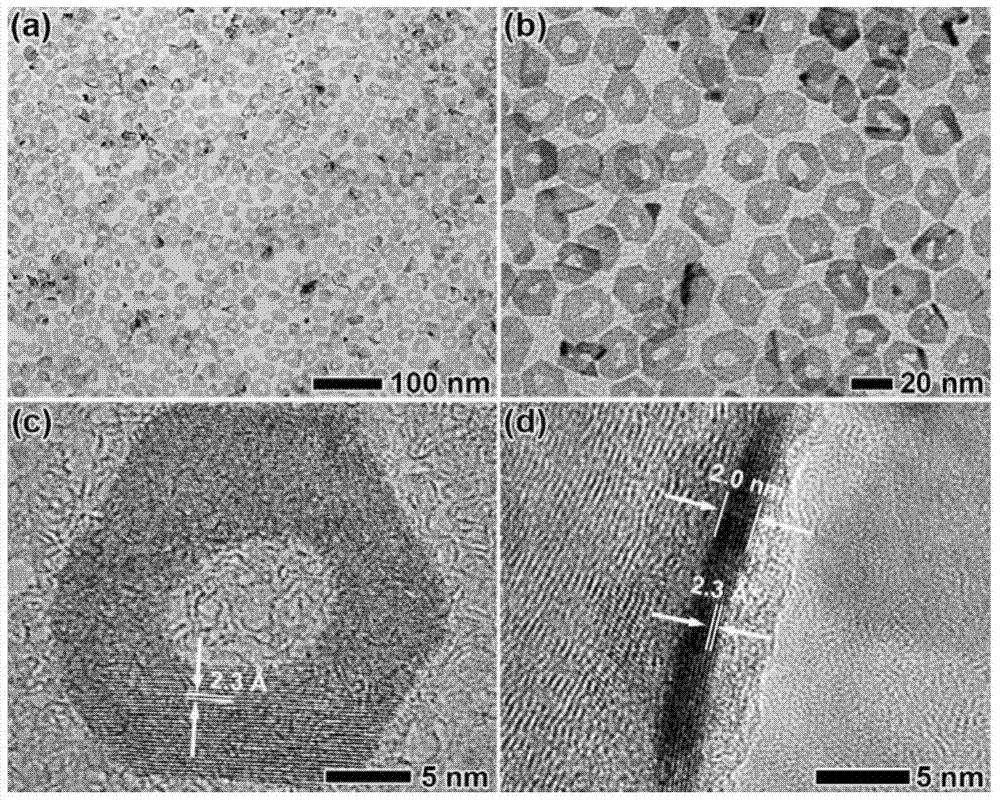

[0044] Step 2, the 4mg palladium nanoplate that obtains in step 1 and 4mg palladium acetylacetonate, 60mg hexadecyltrimethylammonium bromide, 50mg ascorbic acid and 50mg polyvinylpyrrolidone (M w =30000) was added into 10mL N, N dimethylformamide, stirred for 10min to fully dissolve palladium acetylacetonate, cetyl ammonium ...

Embodiment 2

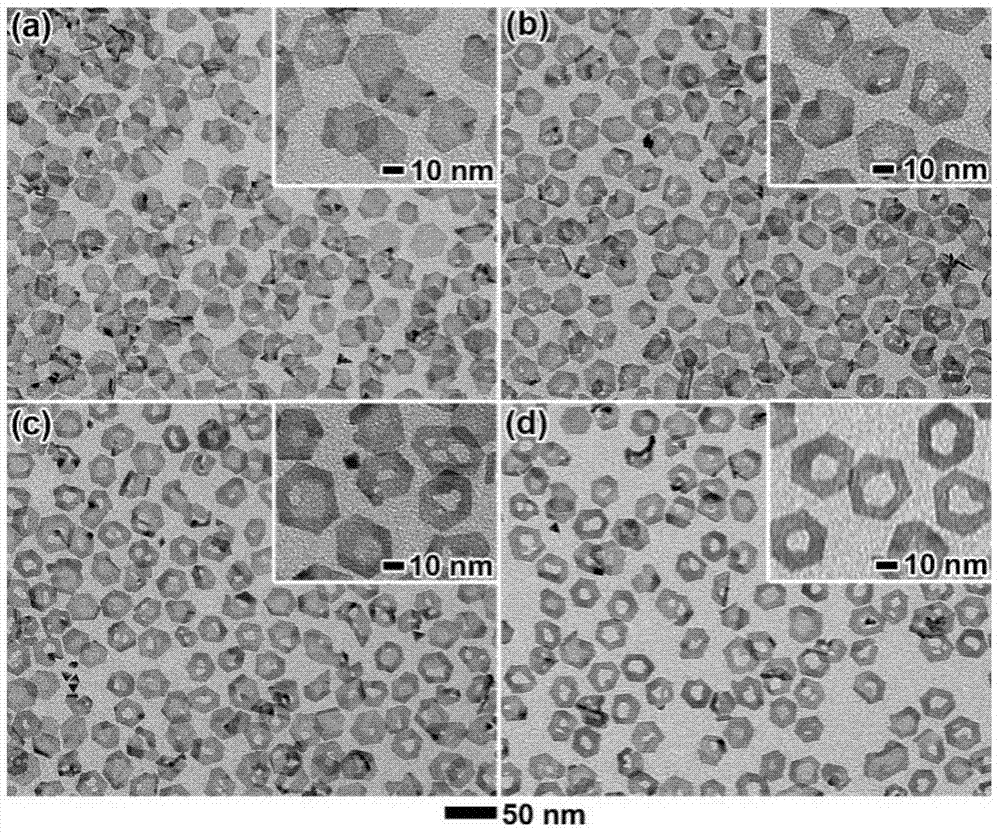

[0048] Step 1. Dissolve 16 mg of palladium acetylacetonate, 60 mg of cetyltrimethylammonium bromide, 100 mg of tungsten carbonyl, 170 mg of citric acid and 30 mg of polyvinylpyrrolidone in 10 mL of N, N dimethylformamide, and stir for 1 h to make each The substance was fully dissolved, and the reaction solution was transferred to a 25mL round bottom flask, and reacted at 80°C for 1h. After the reaction is completed, the reaction solution is centrifuged to obtain hexagonal palladium nanosheets. The morphology of palladium nanosheets is as Figure 5 (a) shown. The hexagonal palladium nanosheets have a thickness of 1.0 nm and an average side length of 6.4 nm.

[0049] Step 2, the 4mg palladium nanoplate that obtains in step 1 and 4mg palladium acetylacetonate, 30mg hexadecyltrimethylammonium bromide, 50mg ascorbic acid and 50mg polyvinylpyrrolidone (M w =30000) was added in 10mLN, N dimethylformamide, stirred for 10min to fully dissolve palladium acetylacetonate, cetyl ammoniu...

Embodiment 3

[0051] Step 1. Add 16 mg of palladium acetylacetonate, 60 mg of cetyltrimethylammonium bromide, 100 mg of tungsten carbonyl, 50 mg of citric acid and 30 mg of polyvinylpyrrolidone into 10 mL of N, N dimethylformamide, and stir for 1 h to make each The substance was fully dissolved, and the reaction solution was transferred to a 25mL round bottom flask, and reacted at 80°C for 1h. After the reaction is completed, the reaction solution is centrifuged to obtain hexagonal palladium nanosheets. The morphology of palladium nanosheets is as Figure 5 (b) shown. The hexagonal palladium nanosheets have a thickness of 1.1 nm and an average side length of 24.5 nm.

[0052] Step 2, the 4mg palladium nanoplate that obtains in step 1 and 4mg palladium acetylacetonate, 120mg hexadecyltrimethylammonium bromide, 50mg ascorbic acid and 50mg polyvinylpyrrolidone (M w =30000) was added into 10mL N, N dimethylformamide, stirred for 10min to fully dissolve palladium acetylacetonate, cetyl ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com