Process unit for removing dust and recovering oil from pyrolysis high-temperature oil gas

A technology for process devices and dust removal devices, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of equipment, pipeline valve blockage, large oil and gas dust content, restrictions, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

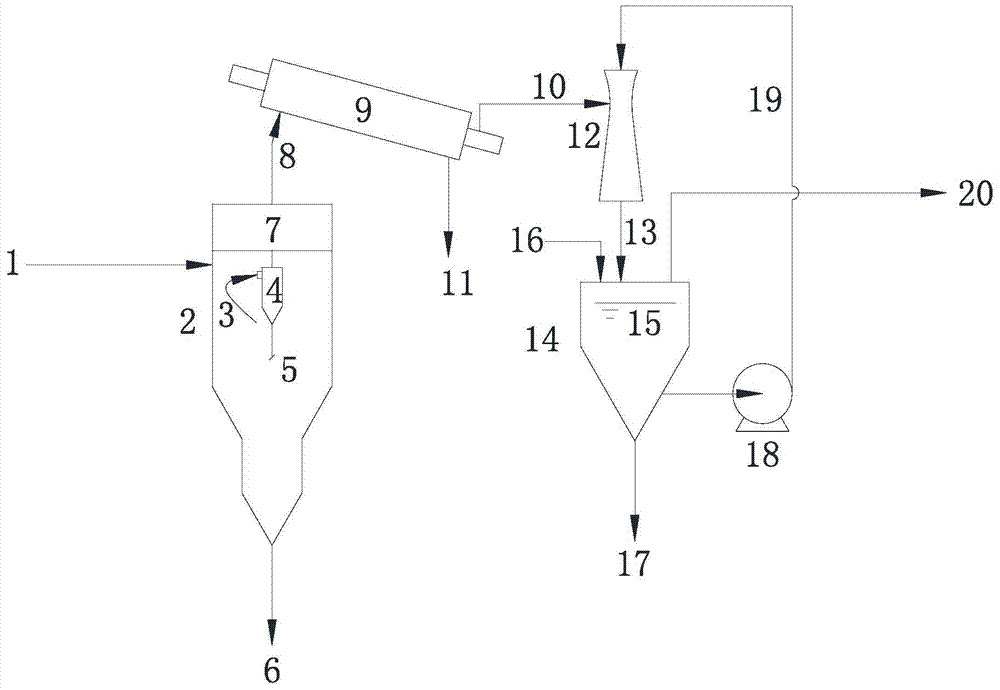

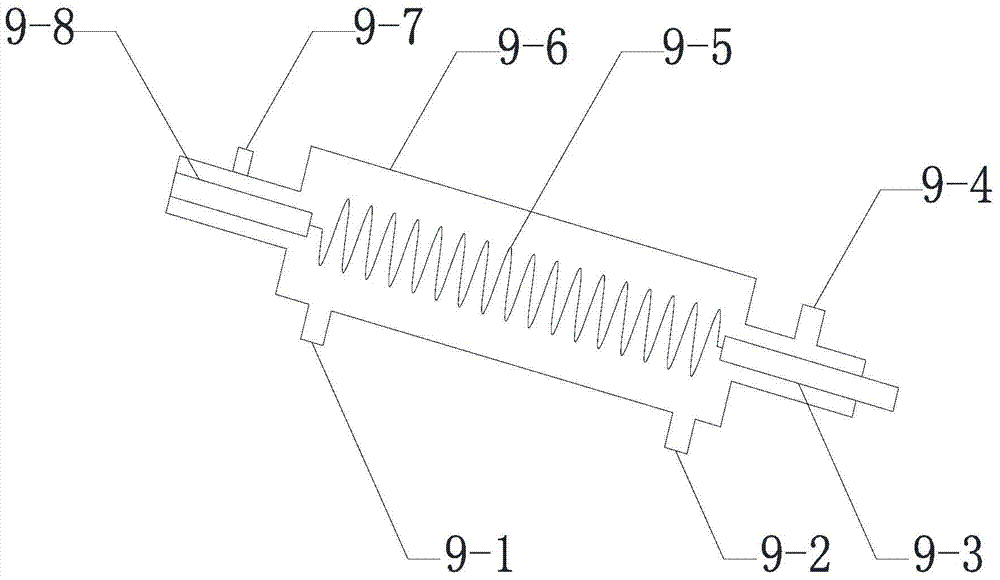

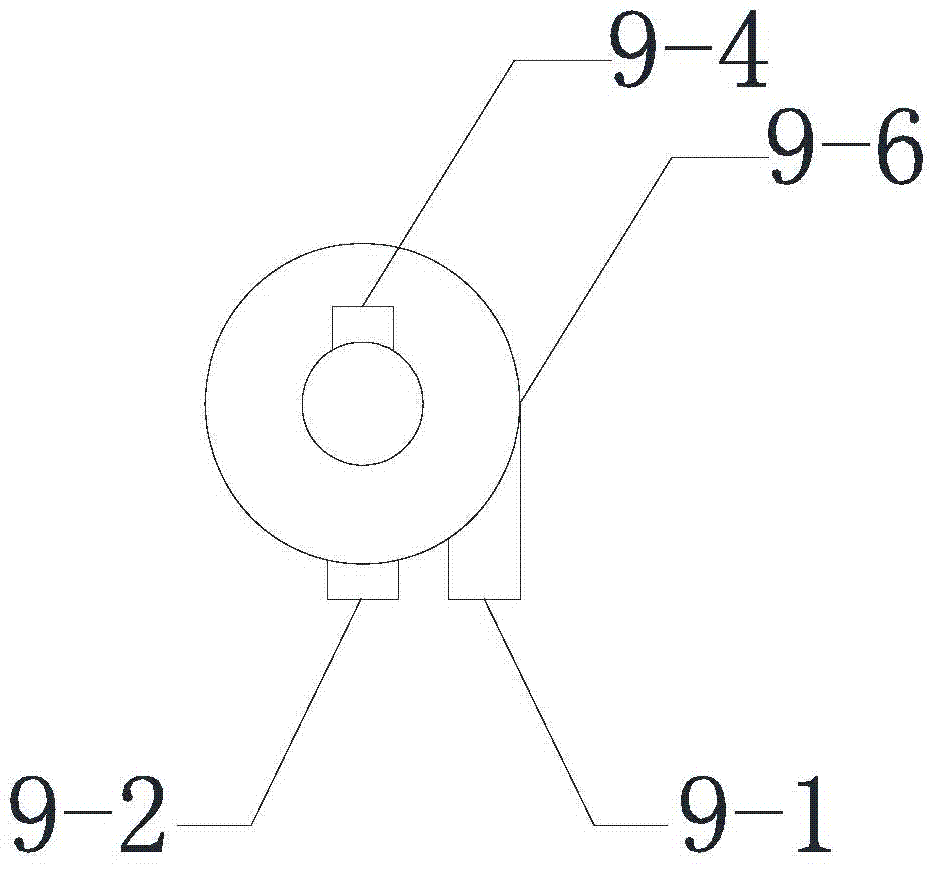

[0026] see Figure 1 to Figure 3, a process device for dedusting and recovering oil by pyrolyzing high-temperature oil gas, including a spiral electrostatic precipitator 9, a parent-child cyclone dust removal device with a high-temperature pyrolysis gas inlet and a plurality of child-cyclone purified gas outlets, and a gas phase port and an oil washing inlet , the Venturi dedusting device at the outlet of residual oil and the outlet of pyrolysis gas purification gas; the spiral electrostatic precipitator 9 includes insulating ceramics 9-3, a cylindrical cylinder 9-6 inclined at 15 degrees and a helical awning in the shape of a helical spring The barbed wire 9-5 and the spiral barbed wire 9-5 are made of high-nickel stainless steel. The outer wall of the cylinder 9-6 is provided with a thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com