Opened type mesh-shaped dynamic separator

A separator and mesh technology, which is applied in the field of open mesh dynamic separators, can solve problems such as unreliable circumferential fixation, easy collapse of metal wires, and poor dynamic balance performance, so as to ensure durability, light weight, and ease of use. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

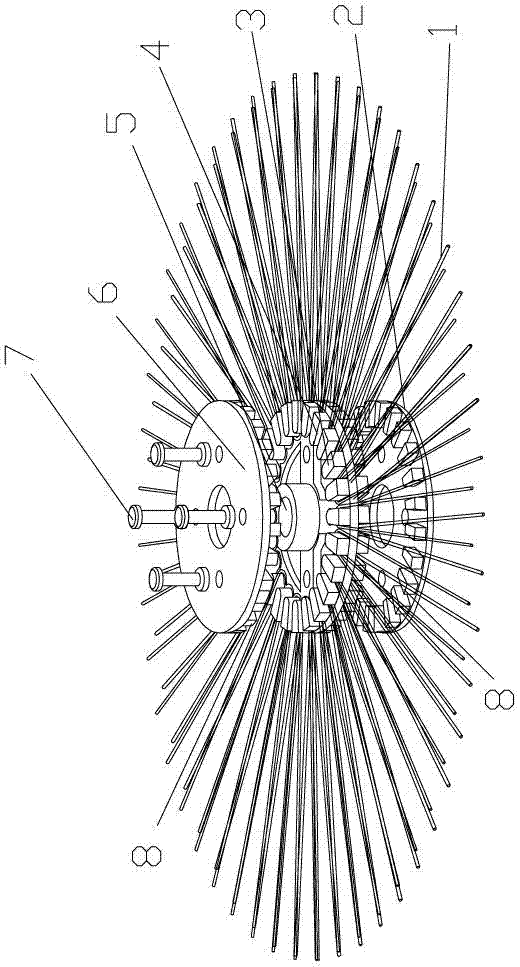

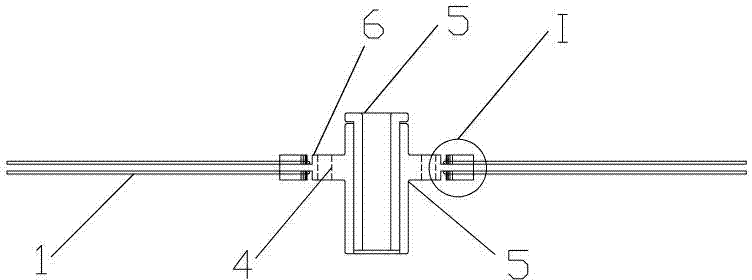

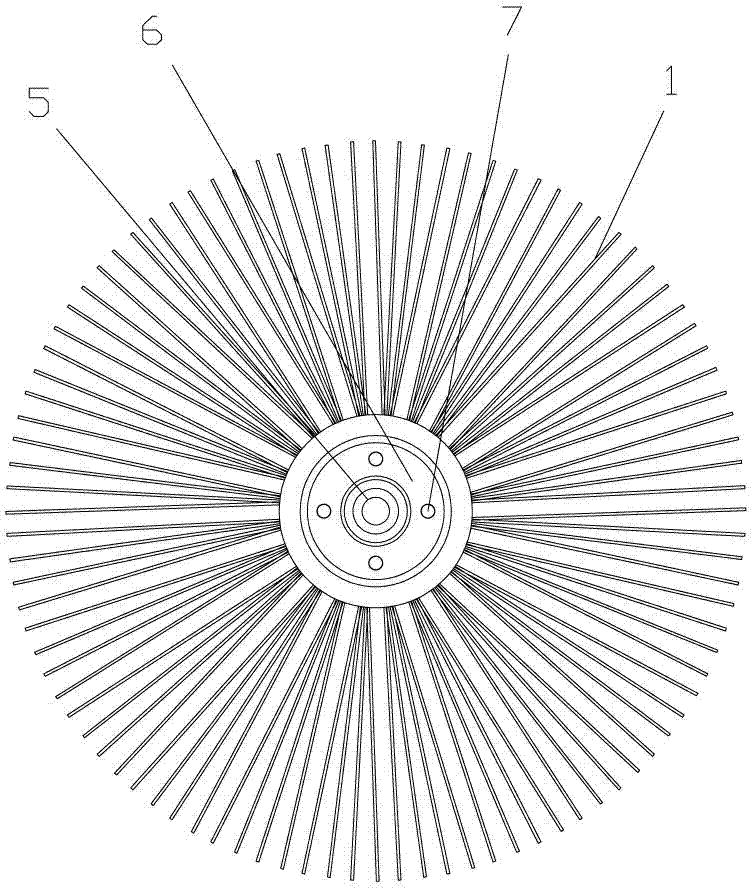

[0023] see figure 1 -6. The present invention has a circular fixed plate 4, and upper and lower glands 6 and 2, especially: a plurality of annular radial bosses 3 evenly distributed are arranged on both sides of the circular fixed plate. A recess is formed between them, and a radially arranged "V"-shaped metal rod 1 is hung on each radial boss to form a radial network arrangement; the sides of the upper and lower glands opposite to the circular fixed plate correspond to each The concave part is provided with a pressing platform 8, which is embedded in the concave part of the circular fixed plate one by one to compress the "V" shaped metal rod; the upper and lower glands 6 and 2 use screws 7 and circular The fixed disk 4 is connected in one body.

[0024] In the present invention, a shaft sleeve structure 5 is provided at the center of the circular fixed disk 4 .

[0025] All "V" shaped metal rods 1 in the present invention are of equal length design.

[0026] The bending an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com