Photovoltaic module mounting rack

A technology for photovoltaic modules and mounting racks, applied in the field of photovoltaic module mounting racks, can solve the problems of easy displacement of fastening blocks, block wiring, reduce the internal space of C-shaped steel, etc., and achieve the effect of saving internal space and not easy to shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

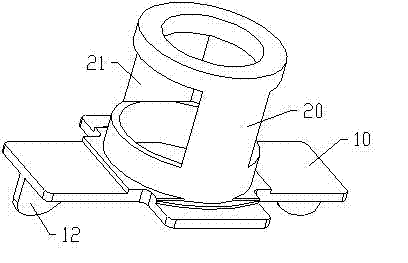

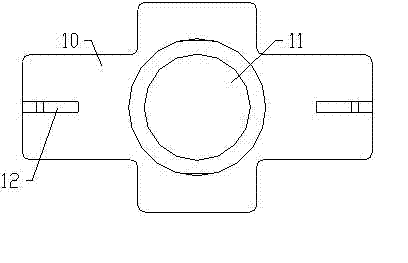

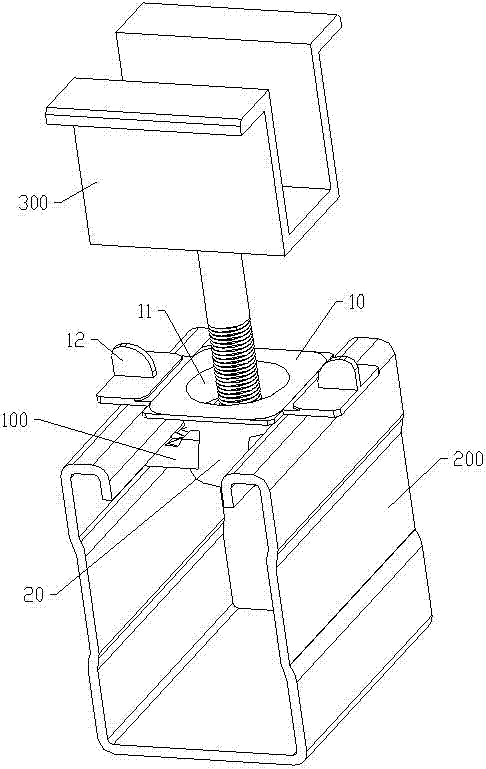

[0012] Examples, see Figure 1 to Figure 3 Shown: a photovoltaic module installation frame, used to fasten the fastening block 100 on the side wall inside the C-shaped steel 200 and realize the suspension of the fastening block 100 . Wherein, the fastening block 100 is provided with screw holes (not shown in the figure) for screwing and cooperating with the screws on the middle pressure block 300 . Furthermore, the photovoltaic module installation frame includes a support plate 10 placed on the upper part of the opening of the C-shaped steel 200 to ensure that the photovoltaic module installation frame does not fall into the C-shaped steel 200 . The middle part of the support plate 10 is provided with a first through hole 11 for the screws on the middle pressing block 300 to pass through. An installation cylinder 20 is integrally formed on the upper surface of the support plate 10 . The mounting cylinder 20 is transparent up and down and its inner cavity is aligned with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com