GIS lead-out bushing hoisting method

A technology of outlet casing and hoisting method, which is applied in the direction of switchgear, electrical components, etc., can solve the problems of increasing investment and increasing project construction costs, and achieve the effects of ensuring equipment safety, saving construction costs, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

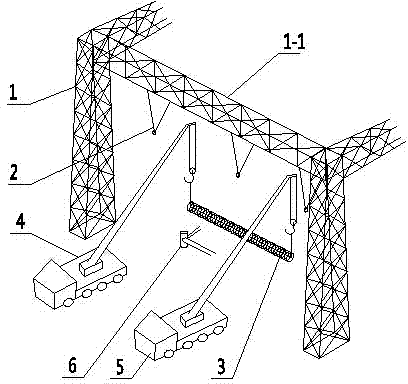

[0032] In this embodiment, the bushing base 6 is in the right position inside the framework, the main crane 4 is a 100-ton crane, the auxiliary crane 5 is a 25-ton crane, and the method for hoisting the GIS outlet bushing 3 includes the following steps,

[0033] Step A, place the GIS outlet sleeve 3 laterally on the outside of the frame, with the head of the GIS outlet sleeve 3 facing to the right;

[0034] Step B, the main crane 4 and the auxiliary crane 5 are arranged side by side on the outside of the frame, the main crane 4 is arranged on the right side, and the auxiliary crane 5 is arranged on the left side; the main crane 4 hangs the head of the GIS outlet bushing 3, and the auxiliary crane 5 hangs The tail of the GIS outlet casing 3; the main crane 4 and the auxiliary crane 5 are hoisted at the same time, and the GIS outlet casing 3 is kept horizontal and lifted by 3 meters;

[0035] Step C, the main crane 4 and the auxiliary crane 5 extend the boom through the lower pa...

Embodiment 2

[0039] In this embodiment, the bushing base 6 is in the left position inside the frame, the main crane 4 is a 100-ton crane, the auxiliary crane 5 is a 25-ton crane, and the method for hoisting the GIS outlet bushing 3 includes the following steps,

[0040] Step A, place the GIS outlet sleeve 3 horizontally on the outside of the frame, with the head of the GIS outlet sleeve 3 facing to the left;

[0041] Step B, the main crane 4 and the auxiliary crane 5 are arranged side by side on the outside of the frame, the main crane 4 is arranged on the left side, and the auxiliary crane 5 is arranged on the right side; the main crane 4 hangs the head of the GIS outlet bushing 3, and the auxiliary crane 5 hangs The tail of the GIS outlet casing 3; the main crane 4 and the auxiliary crane 5 are hoisted at the same time, and the GIS outlet casing 3 is kept horizontal and lifted by 5 meters;

[0042] Step C, the main crane 4 and the auxiliary crane 5 extend the boom through the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com