Condensate throttling control system and safety control method thereof

A condensate water throttling and control system technology, applied in control/regulation system, liquid level control, non-electric variable control, etc., can solve the problem of limited energy storage of deaerator and achieve the effect of efficient and safe utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

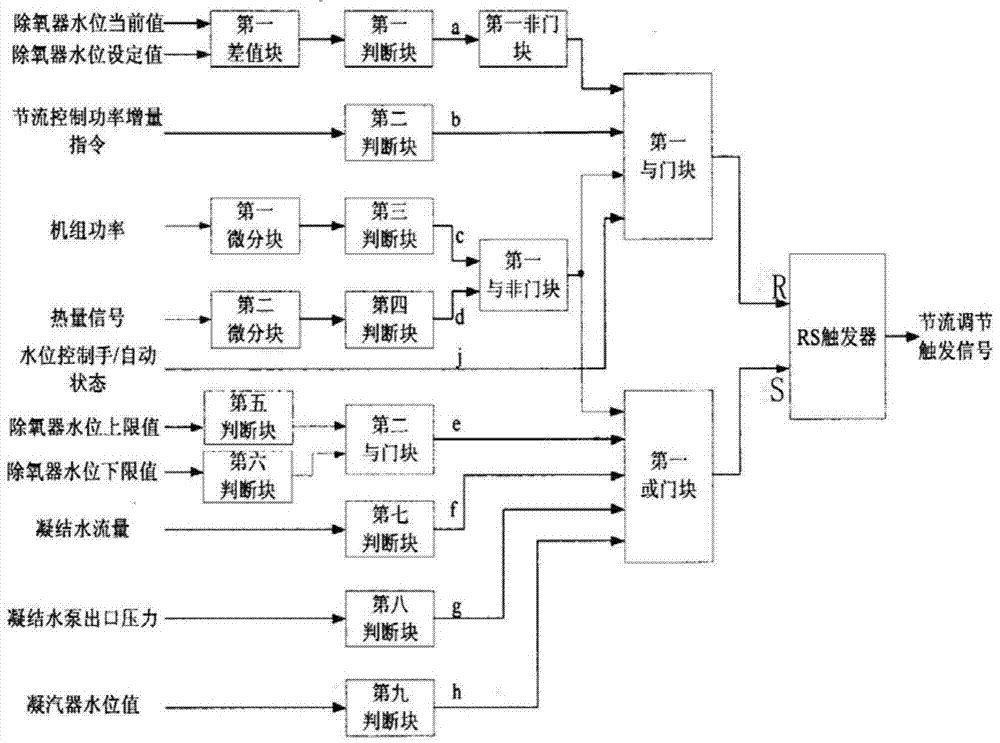

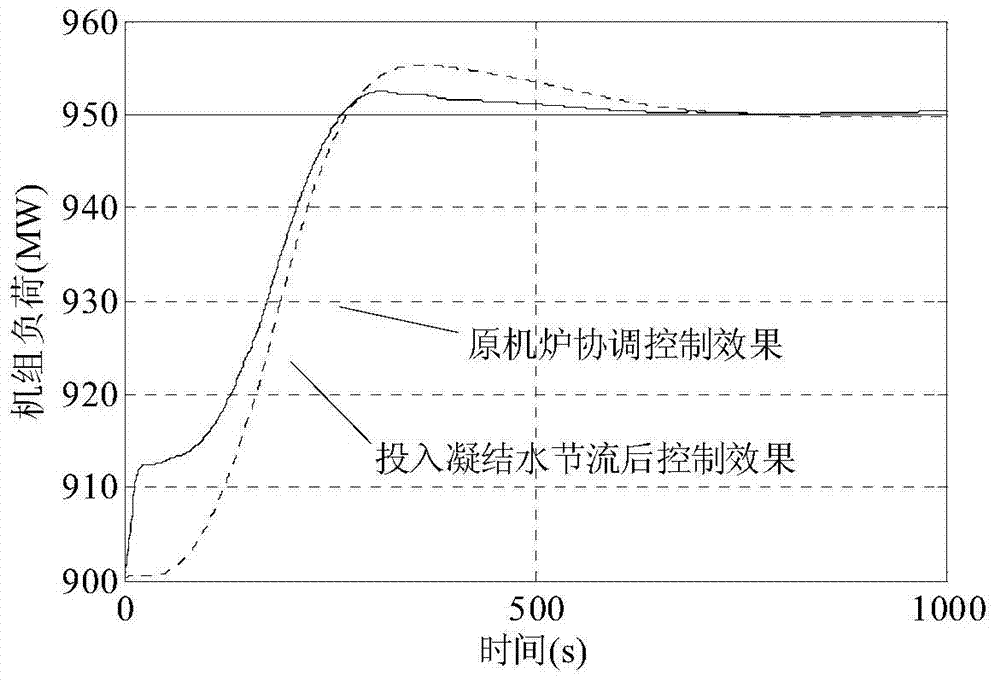

[0051] The present invention provides a condensate throttling control system and its safety control method. Firstly, the condensate adjustment rate range is determined, and the unit energy signal and unit power change rate signal are constructed as the switching / cutting signals for the condensate throttling effect. Perfect protection logic ensures fast and stable control of unit load.

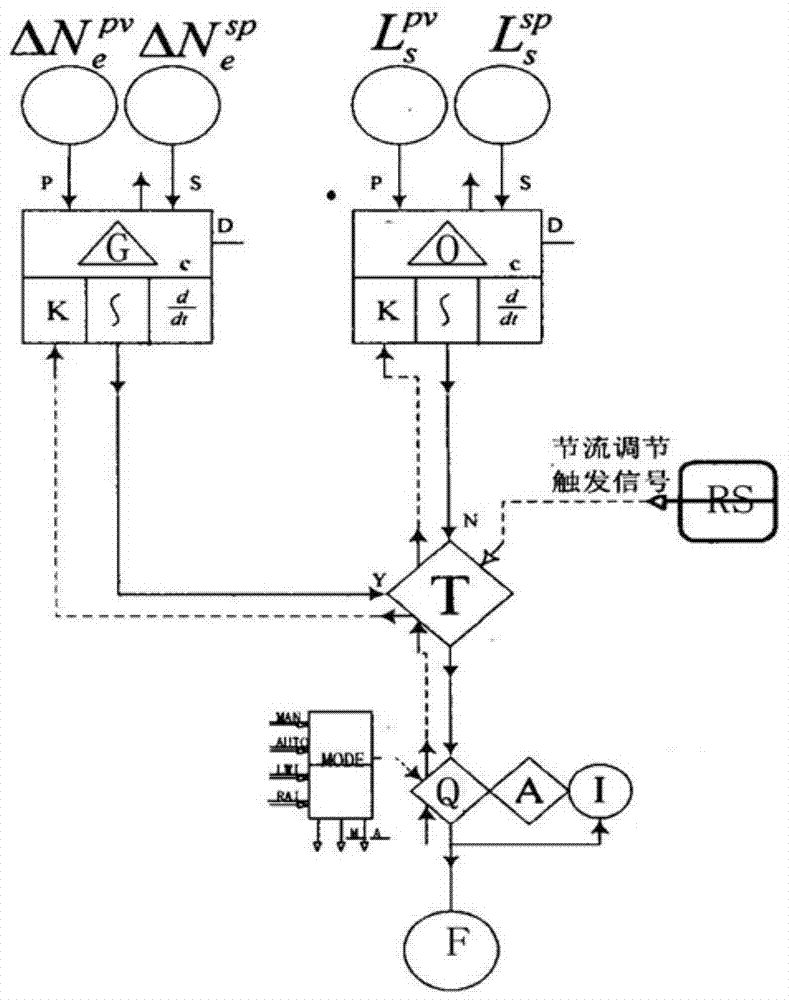

[0052] figure 1 As shown, it is the structural diagram of the condensate throttling control system. By outputting the control signal, the opening of the deaerator upper water electric door can be adjusted to quickly adjust the condensate flow, and then change the extraction flow of low-pressure heaters at all levels, resulting in the load of the unit being increased. Quick response.

[0053] The controller switching module T of the condensate throttling system is respectively connected to the power increment controller G, the deaerator water level controller O and the deaerator water level adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com