Accumulator ultralow-temperature leak test device and method

A technology of leak detection and pressure accumulator, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems such as the inability to detect the amount of gas leakage of the valve, and achieve convenient ultra-low temperature The effect of leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

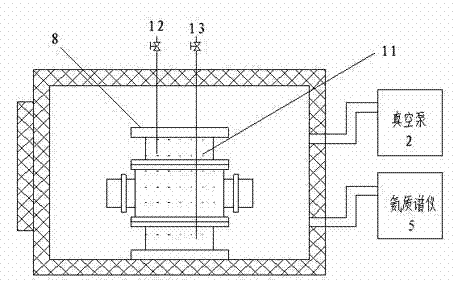

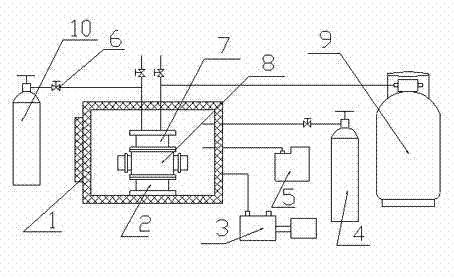

[0028] Below in conjunction with accompanying drawing, the patent of the present invention is described in further detail. But the present invention is not limited to the following description.

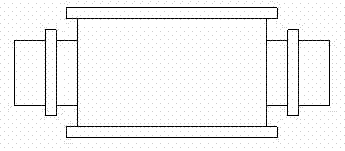

[0029] The structure of an example of the accumulator according to the present invention is as follows: figure 1 As shown, a dumbbell-type metal bellows structure is adopted, including: a liquid chamber, a shell, a bellows, etc.; wherein, the contact surface of the shell and the bellows is a sealing surface. The design technical requirements are as follows: pre-fill P=1.1MPa normal temperature helium in the air chamber 5 of the pressure accumulator bellows, and fill the liquid chamber with 0.7MPa normal temperature helium to maintain the pressure, place the pressure accumulator in a liquid nitrogen environment, Check the airtightness between the diaphragm box and the shell, and the air leakage is required to be no more than 1×10 -6 Pa·m3 / s, the air-conditioning switch is not allowed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com