Quantitative measurement caliper gauge

A technology of quantitative measurement and caliper, which is applied in the field of measuring instruments, can solve the problems of low measurement accuracy, complex structure of caliper with watch, unreasonable measurement principle, etc., and achieve the effect of high measurement accuracy, convenient quality control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

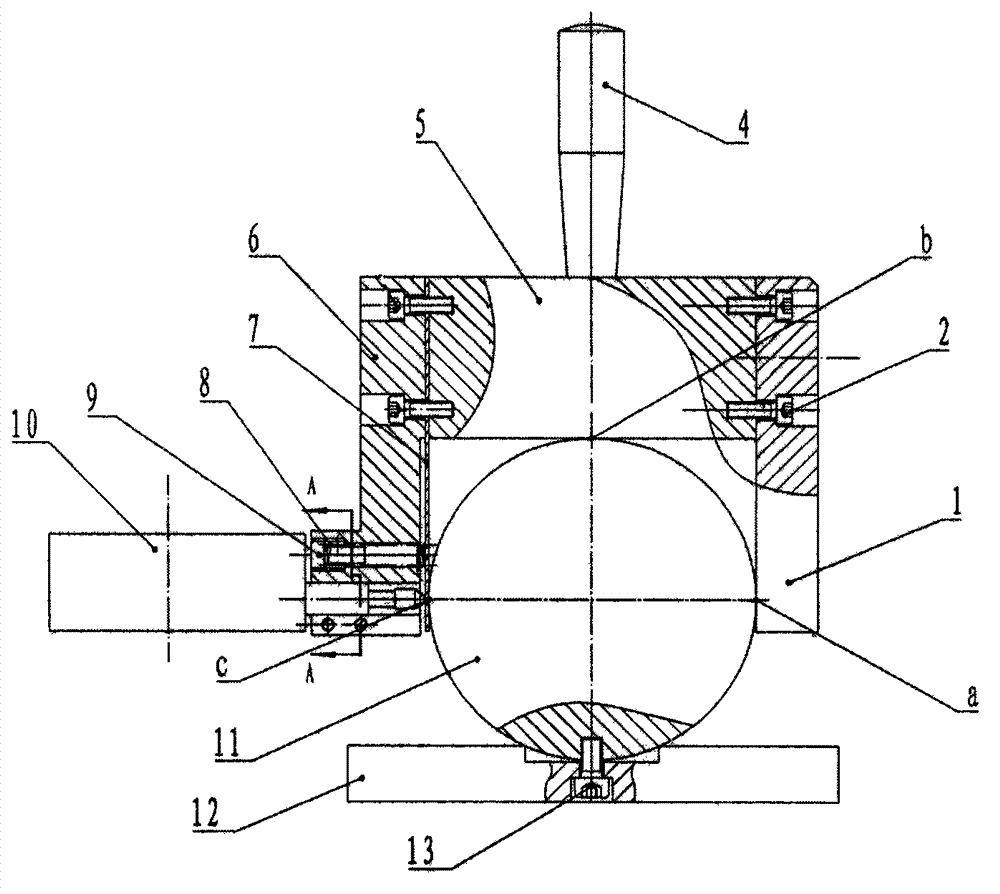

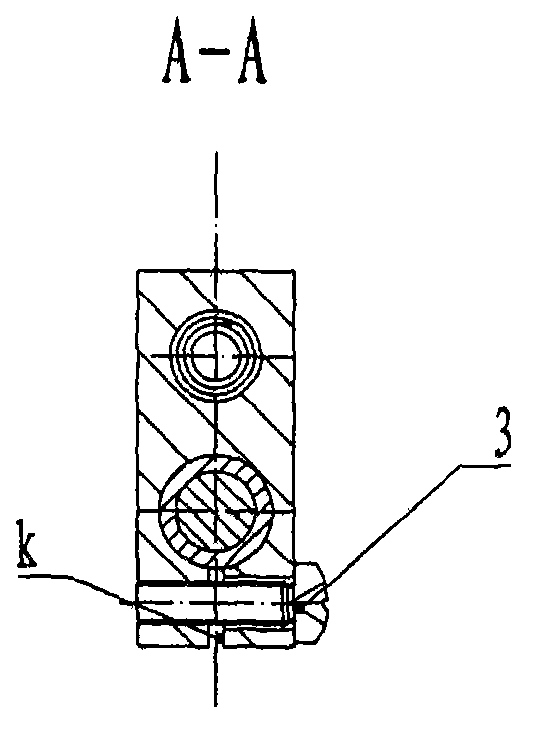

[0024] Embodiment 1: see specification attached figure 1 , attached figure 2 And attached image 3 , the quantitative measuring caliper of the present invention comprises web 5, fixed measuring arm 1, elastic measuring arm 7, dial indicator 10, dial indicator fixing frame 6, spring 8, handle 4, measure zero gauge 11 and zero gauge Base12. The web is a rectangular plate. The length of the web is equal to the average value of the maximum tolerance size and the minimum tolerance size of the part to be measured. The two sides of the length direction of the web are parallel to each other; the fixed measuring arm is a rectangular block with a The hole connected to the plate is fixed and connected to one side of the web length direction with screws. One surface of the measuring arm should be in contact with the workpiece to be measured, and the contact point is a, so the contact end of the fixed measuring arm and the workpiece should be cantilevered out , the protruding length is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com