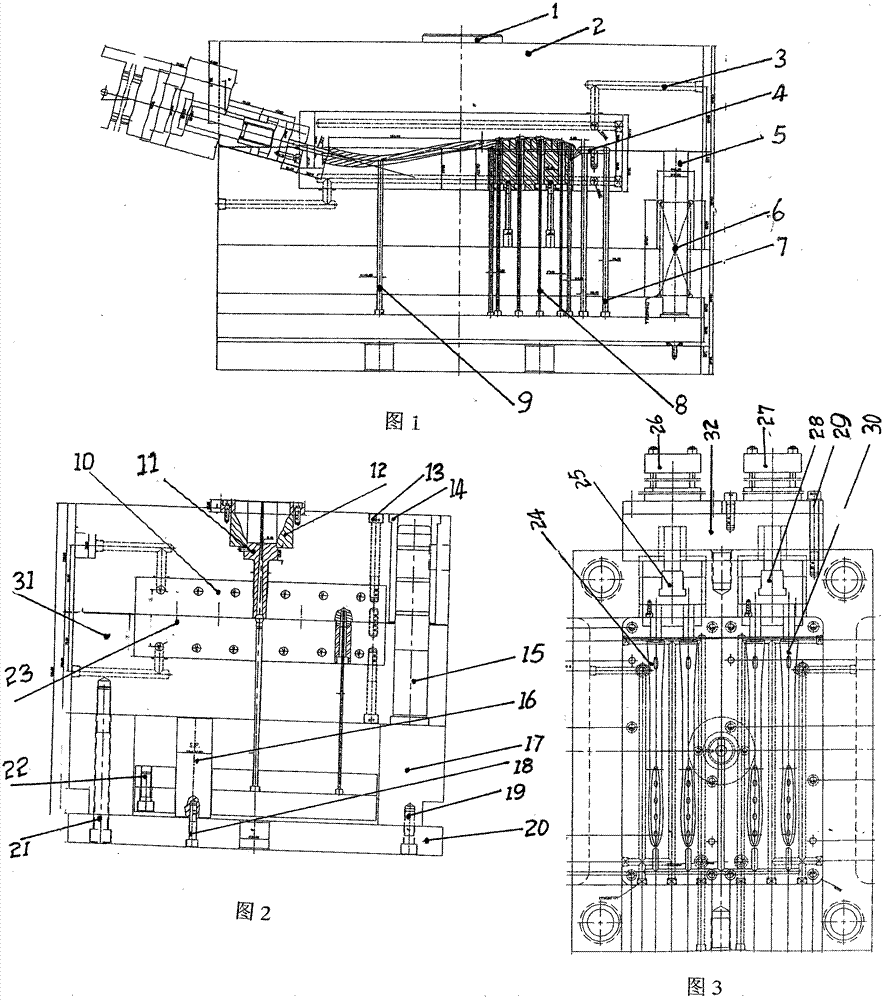

Inclined core-pulling mechanism for hydraulic cylinders in metal die-casting die

A technology of die-casting molds and hydraulic cylinders, applied in the field of side core-pulling mechanisms, can solve problems such as low production efficiency, increased volume, inconvenient installation and debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] As shown in the figure is the oblique core-pulling mechanism of the hydraulic cylinder in the metal die-casting mold. The point of this model is that it relies on the hydraulic cylinder installed on the outer side of the mold to drive the core-pulling of the molded parts. Its advantage is that the transmission is stable and can be The hydraulic system is set according to the core-pulling force required by the casting and the core-pulling stroke, so that a larger core-pulling force and a longer core-pulling stroke can be obtained. When in use, it only needs to be connected with the lateral core-pulling part in the mold, and the core-pulling can be realized after adjustment. This mold utilizes this feature of the hydraulic cylinder and applies it to the core pulling of the oblique hole of the casting. Due to the special shape of the casting, the shape of the casting is composed of multiple outer arcs and inner arcs, and there is an inclined hole at the end of the casting....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com