Graphite composite grounding protection material and preparation method thereof

A technology of composite grounding and protective materials, applied in the direction of connecting contact materials, connections, line/collector components, etc., can solve the problems of grounding metal surface corrosion, affecting the effect of grounding grid grounding resistance reduction, and being easily corroded, etc., to achieve Stable in nature, prolonging the effect of resistance reduction protection, and the effect of not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

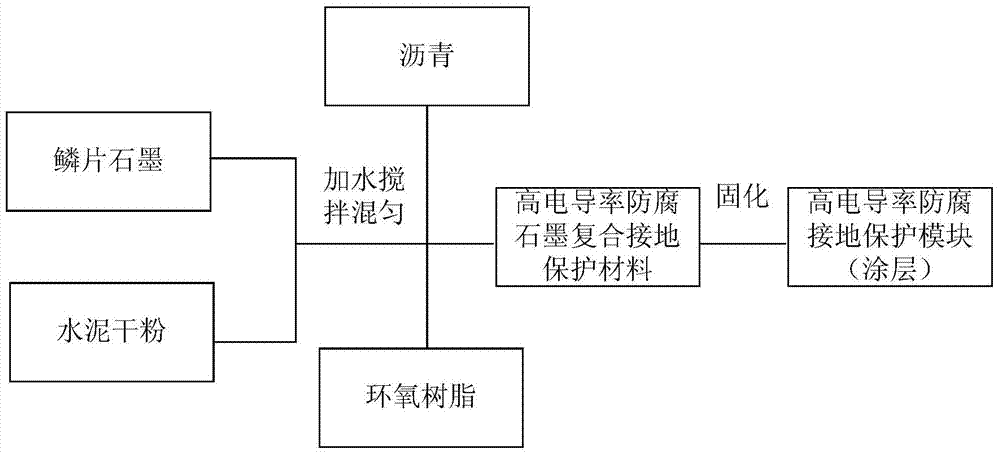

[0021] A preparation method of a graphite composite grounding protection material in this embodiment (the schematic diagram of the preparation process is as follows figure 1 Shown): Add 40% flake graphite and 50% dry cement powder in deionized water, add water and stir evenly, then add 5% asphalt and 5% epoxy resin and mix evenly to obtain graphite composite ground protection material.

[0022] The material is evenly coated on the outer surface of the graphite composite grounding body or the metal connector to form a protective coating, and the resistivity of the material is about 1.9Ωm after curing.

Embodiment 2

[0024] The preparation method of a graphite composite grounding protection material in this embodiment: Add flake graphite with a volume fraction of 70% and 25% cement dry powder in deionized water, add water and stir evenly, then add 2% asphalt and 3% epoxy resin After uniform mixing, the graphite composite grounding protection material is obtained.

[0025] The material is evenly coated on the outer surface of the graphite composite grounding body or the metal connector to form a protective coating, and the resistivity of the material is about 0.1Ωm after curing.

Embodiment 3

[0027] The preparation method of a graphite composite ground protection material in this embodiment: add flake graphite with a volume fraction of 50% and cement dry powder with a volume fraction of 45% in deionized water, add water and stir evenly, then add 3% asphalt and 2% epoxy resin After uniform mixing, the graphite composite grounding protection material is obtained.

[0028] The material is evenly coated on the outer surface of the graphite composite grounding body or the metal connecting piece to form a protective coating, and the resistivity of the material is about 0.3Ωm after curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com