Field bus controller and method

A field bus and controller technology, applied in program control, comprehensive factory control, electrical program control, etc., can solve problems such as low down-loading efficiency, huge service, training and technical support costs, and difficulties in handling engineering and technical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

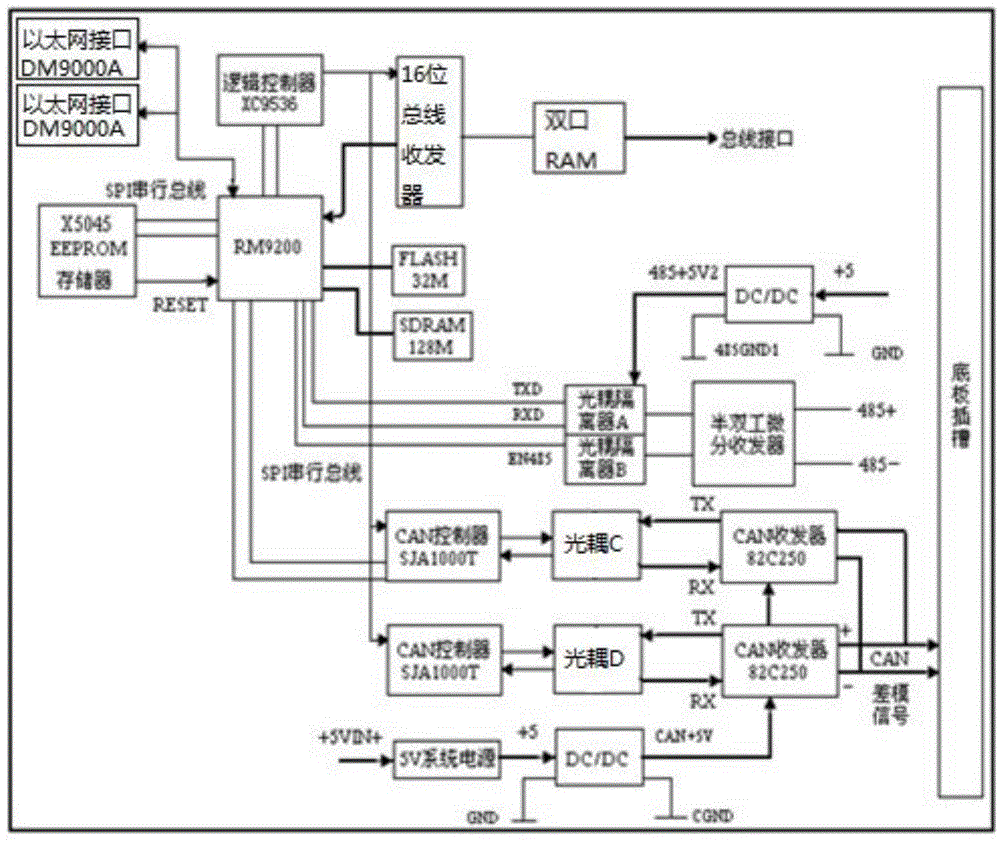

[0046] like figure 1As shown, a field bus controller of the present invention includes two redundant Ethernet interfaces DM9000A provided to the outside, RM9200 connected to the Ethernet interface DM9000A through a bidirectional data bus, and the data pins SD0 to SD15 of the Ethernet interface DM9000A Connect to the data pins D0 to D15 of RM9200 respectively, among which SD0 is connected to D0, SD1 is connected to D1, and so on, and SD15 is connected to D15; the CS# pin of the Ethernet interface DM9000A is connected to the NCS3 pin of RM9200, and the The RESET pin is connected to PA25 of RM9200, the INT pin of Ethernet interface DM9000A is connected to PA23 of RM9200, the CMD pin of Ethernet interface DM9000A is connected to A2 pin of RM9200; it also includes dual-port RAM, two-way CAN The bus controller SJA1000T, the logic controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com