A Calibration Method for Temperature and Resistance of Cesium Beam Tube Thermistor

A thermistor and calibration method technology, applied in thermometers, thermometer testing/calibration, heat measurement, etc., can solve problems such as insulation difficulties, cesium furnace damage, short circuit, etc., to avoid oxidation and damage, avoid damage, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below:

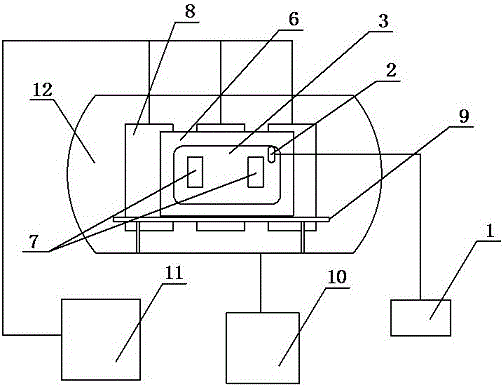

[0031] like figure 2 As shown, a calibration system includes a digital multimeter 1, a heating belt 8, a support base 9, an air extraction unit 10, a computer 11 and a calibration room 12, the heating belt 8 and the support base 9 are rigidly connected in the calibration room 12, and the heating belt 8 Evenly arranged in the calibration room 12 to ensure the uniformity of heating in the calibration room 12, the support seat 9 is arranged in the middle of the calibration room 12 with the table facing upwards, and is used to place the calibrated cesium beam tube 6, and the calibration room 12 is a closed cavity One end of the calibration room 12 is provided with a sealed door with a fluorine rubber ring, the air extraction unit 10 is connected to the calibration room 12 through a pipeline, and the computer 11 controls the temperature rise and fall operation of the heating belt 8 .

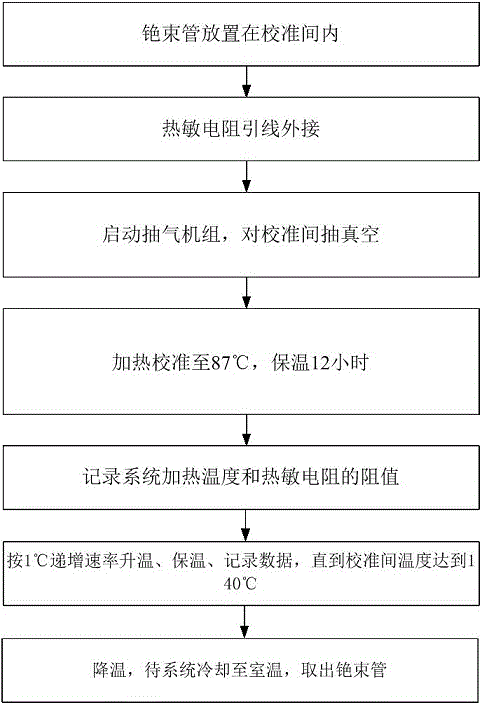

[0032] like image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com