Energy saving furnace

An energy-saving furnace and furnace bottom technology, which is applied in the direction of household furnace/stove, lighting and heating equipment, solid heating fuel, etc., can solve the problem of low safety factor of defluoridation and other harmful gases, loss of inhalation and heat recovery, and endangering human health and life problems, to achieve the effect of high cost performance, low cost and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

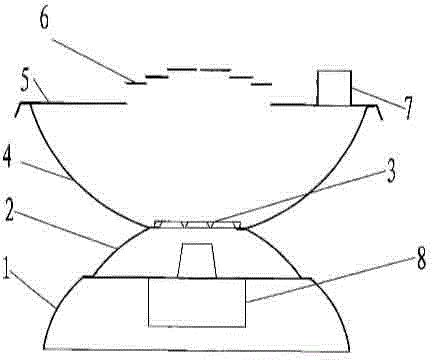

[0013] The structure of combustion chamber 2 and furnace bottom 1 is an inner hollow bottomless bowl-shaped structure, with inner diameters from small to large and placed upside down under stove 3, the inner diameter of combustion chamber 2 is smaller than that of furnace bottom 1, and the large diameter of combustion chamber 2 is fixed on the furnace bottom 1 small bore above. A combustion chamber 4 is arranged above the small diameter of the combustion-supporting chamber 2 . The combustion chamber 4 is an inner hollow bottomless bowl-shaped structure, and forms a gourd shape when it is docked with the combustion-supporting chamber 2 . Place the heating panel 5 at the large diameter of the combustion chamber 4, and set the dust removal pipe 7 above the heating panel 5. Place heat booster rings 6 with different calibers on the heating panel 5 to adjust the firepower. In the combustion-supporting chamber 2 and the furnace bottom 1, a slag removal box 8 is arranged below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com