Pumping device of garbage pumping sanitation vehicle

A sanitation vehicle and pump suction technology, which is applied to the appliance field of garbage sanitation vehicles, can solve the problems of bodily injury, large exhaust gas inhalation of sanitation workers, and difficulty in cleaning work by sanitation workers, and achieves the effect of enhancing strength and preventing clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

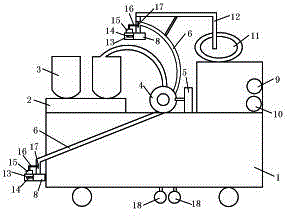

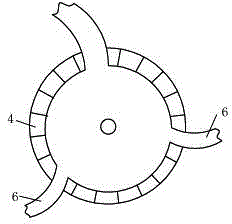

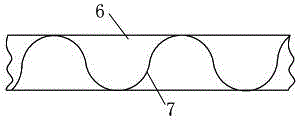

[0016] Combine below Figure 1 to Figure 4 Specific description embodiment:

[0017] Such as Figure 1 to Figure 4 As shown, the pump suction garbage sanitation vehicle adopting an anti-corrosion centrifugal fan includes a body 1, the body 1 is provided with a dumping device 2 for automatically dumping garbage, and the dumping device 2 is provided with a number of garbage cans 3; The car body 1 is provided with an anti-corrosion centrifuge 4 and a power machine 5, the anti-corrosion centrifuge 4 is connected with the power machine 5 and generates suction through the power machine 5, the discharge end of the anti-corrosion centrifuge 4 communicates with the trash can 3, the inlet of the anti-corrosion centrifuge 4 The feed end is connected with a feed pipe 6, and a round skeleton rod frame 7 spirally coiled is arranged in the feed pipe 6; The material inlet mask 8 communicates with the other end of the feed pipe 6; the front part of the vehicle body 1 is provided with a contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com