Automatic unhooking machine of tyre conveying line

An automatic decoupling and conveying line technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of tire decoupling time, high labor intensity, low production efficiency, etc., achieve simple structure, reduce labor intensity, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

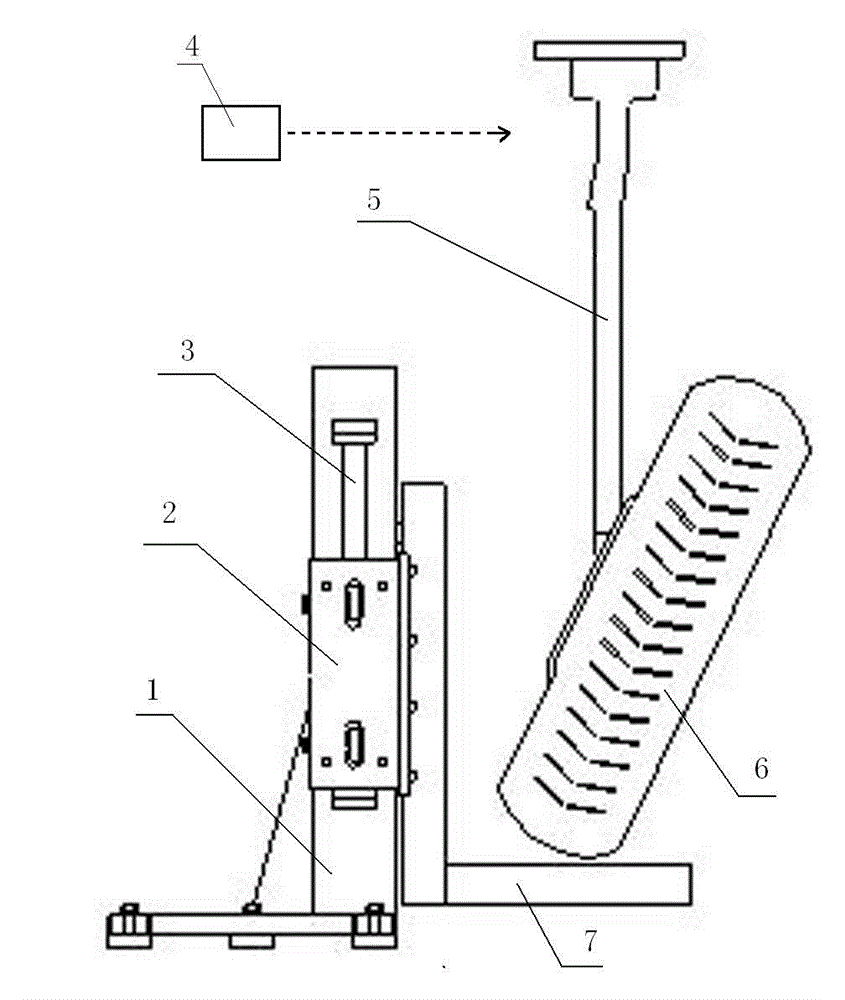

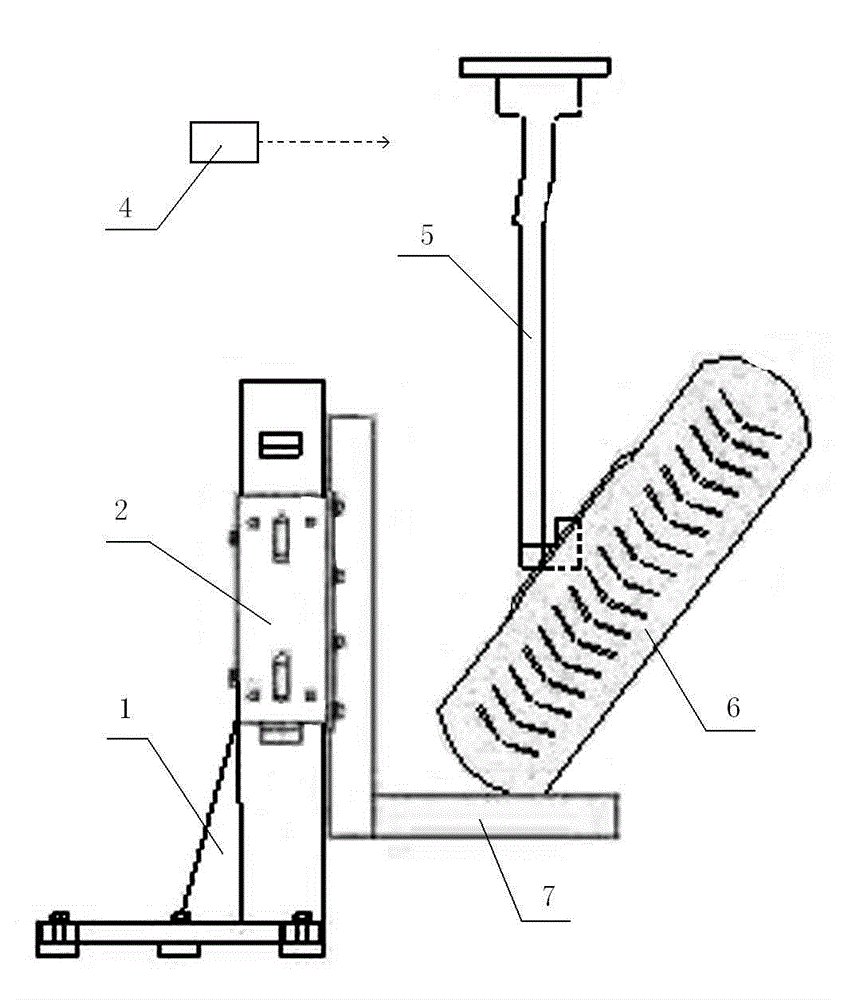

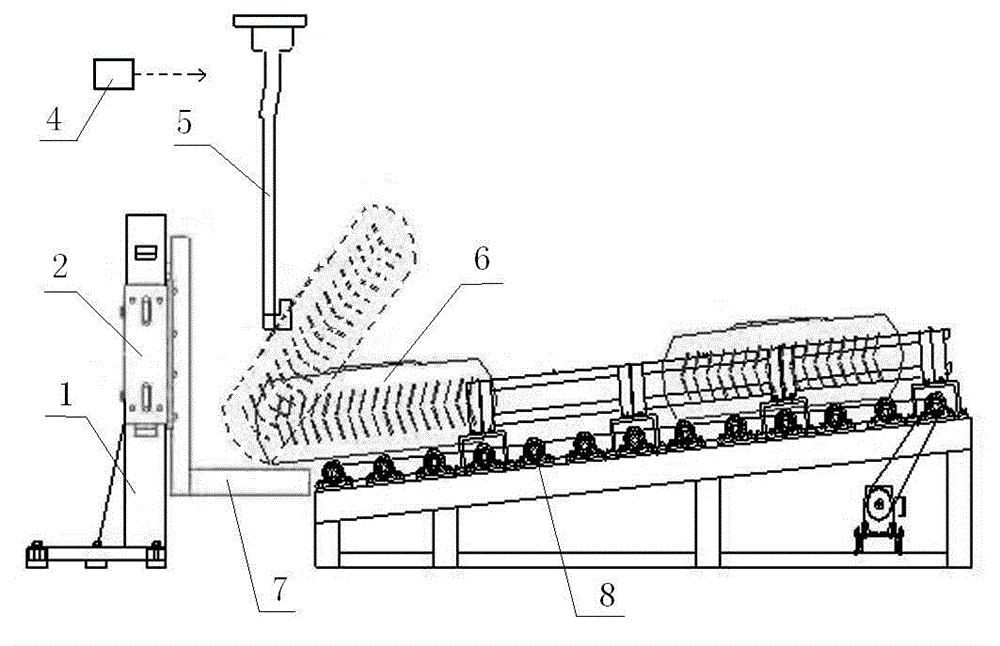

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0016] Figure 1 to Figure 4 The automatic decoupling machine for the tire conveying line includes a jacking support 1 with guide rails on opposite sides, a guide slider 2 slidingly connected to the guide rails on both sides, and in the jacking support 1 between the two guide sliders 2 A drive cylinder 3 is provided, and the drive cylinder 3 is controlled by an automatic induction controller, which is composed of a photoelectric sensor 4 and a power control circuit (not shown in the figure); the guide slider 2 is driven by the drive cylinder 3, and the drive cylinder 3 is a cylinder, its cylinder body is fixedly connected with the jacking support 1, and its piston rod is fixedly connected with the two guide sliders 2 through a connecting rod, and the two guide sliders 2 move up and down through the expansion and contraction of the piston rod; the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com