Correcting device of unidirectional conveyer

A deviation correction device and conveyor technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve problems such as broken belts, worn belts, and belt deviations, so as to save labor and realize automatic belt deviation correction. Adjust the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

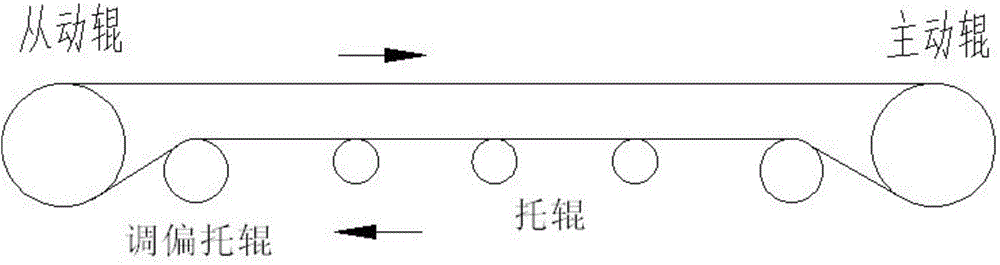

[0015] figure 2 Shown is the schematic structural view of the one-way conveyor deviation correction device of the present invention, and the one-way conveyor deviation correction device is installed at the belt conveyor tail, below the belt (such as Figure 4 shown), the position between 300mm and 500mm from the front end of the tensioning and deflecting roller of the driven roller.

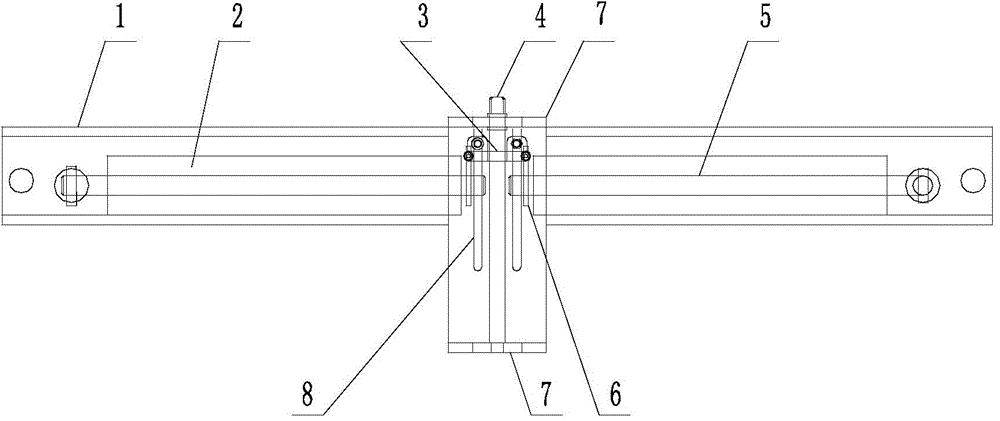

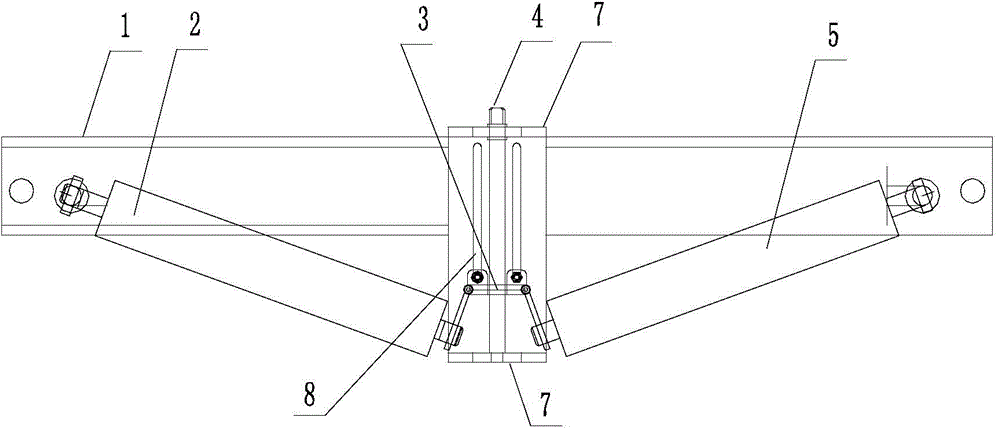

[0016] The deviation correction device of the one-way conveyor comprises a fixed seat plate 1, a left side deviation correction roller 2 installed on the fixed seat plate 1, a right side deviation correction roller 5, a screw positioning plate 7, and the length of the fixed seat plate 1 is the belt conveyor wall. The width of the plate frame, the left side deviation correction roller 2 and the right side deviation correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com