Flat carrier vehicle

A transporter and flatbed technology, applied in the direction of goods transporter, transport objects, transportation and packaging, etc., can solve the problems such as the inability to effectively alleviate road bumps, the inability of locomotives to climb, and the inability to effectively fix the transported locomotives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

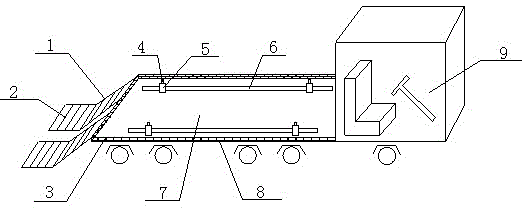

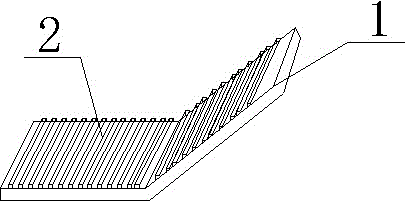

[0014] Such as figure 1 As shown, a flatbed transport vehicle includes a ladder 1, a vehicle body panel 8 and a cab 9, the ladder 1 is connected to the vehicle body panel 8, the vehicle body panel 8 is connected to the cab 9, and the ladder 1 is provided with a non-slip The tooth groove 2 can make the locomotive to be transported safely and quickly climb onto the flat transport vehicle. The shock absorbing layer 3 is provided on the flat plate 8 of the body, which can effectively alleviate the road bumps during the transport process, and will not cause the transported locomotive to be damaged. damaged, the shock absorbing layer 3 is connected with a loading plate 7, the loading plate 7 is provided with a guide rail 6, the guide rail 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com