Induction-heating pipe bender

A technology of induction heating and pipe bending machine, which is applied in the field of pipe bending machines, can solve the problem of small bending range of steel pipes, and achieve the effect of increasing the bending arc length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

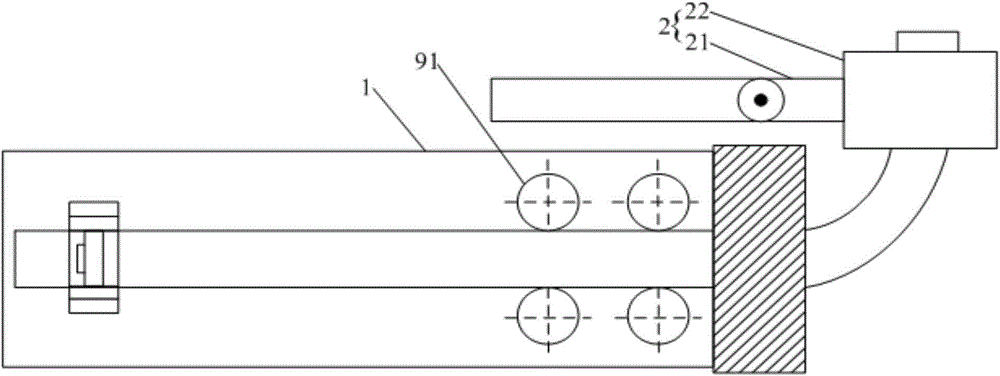

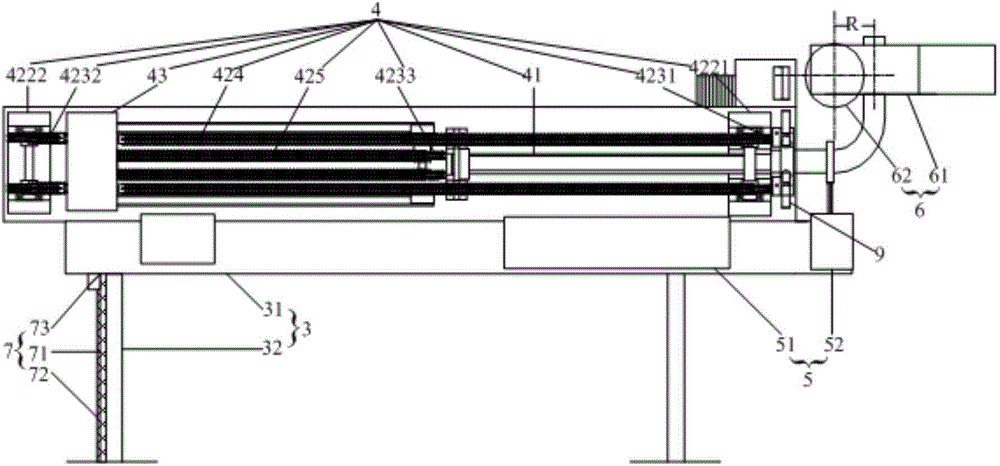

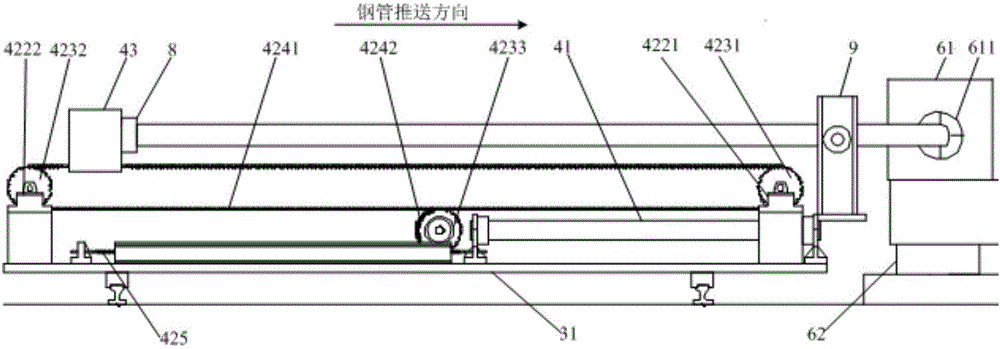

[0029] The induction heating pipe bending machine provided by the embodiment of the present invention solves the problem that the rocker arm type induction heating pipe bending machine introduced in the background art has a large limitation on the bending range of the steel pipe.

[0030] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the embodiments of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention are described below in conjunction with the accompanying drawings The program is described in further detail.

[0031] In this section, the orientation words such as "front" and "rear" are relative to the position of the machine tool system and the fixture system, and the direction of the machine tool system toward the fixture system is "front", and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com