Secondary circuit wire straightening and cutting tool

A secondary circuit and wire technology, which is applied to the installation of cable installation devices, electrical components, and cables, can solve problems such as chaotic cable connections in the mechanism box, damage to the insulation layer of wires, and damage to the stability of the power system, so as to improve maintenance Effects on workmanship, damage reduction, efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

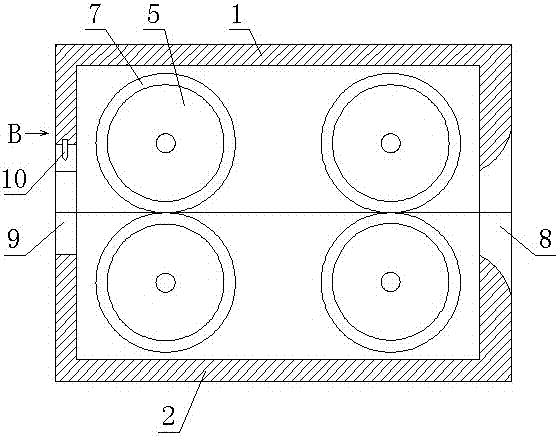

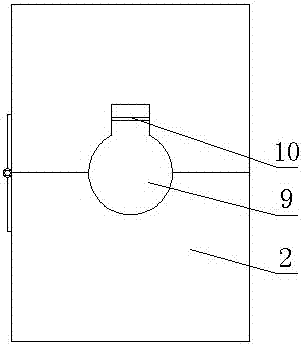

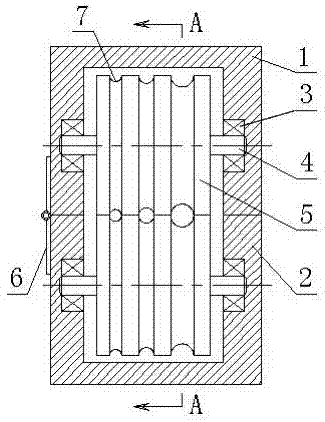

[0018] As shown in the figure, the tool for straightening and cutting secondary circuit wires has a housing, which is composed of upper and lower housings 1 and 2 that are folded and closed by hinges 6 . Two pairs of rolls 5 located in the same vertical plane are arranged in the housing, and each pair of rolls 5 is composed of upper and lower rolls fixed respectively in the upper and lower housings 1, 2 by utilizing the rotating shaft 4. The rotating shaft 4 rotates under the drive of the roll 5, and the upper and lower housings 1, 2 are provided with bearings 3 corresponding to the positions where the rotating shaft 4 is fixed. The rotating shaft 4 is connected with the roll 5 by a key. The material of the roll 5 is Bakelite. The surrounding surfaces of the upper and lower rollers are bonded and correspondingly provided with a plurality of wire slots 7 to accommodate wires of various sizes, and the housing is respectively provided with a wire inlet 8 and a wire outlet 9 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com